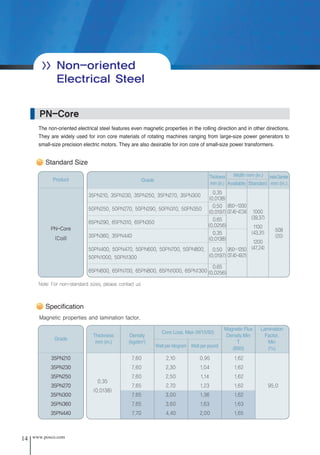

The document details the manufacturing process and specifications of electrical steel produced in Korea, highlighting its excellent performance and energy efficiency. It discusses grain-oriented and non-oriented electrical steel, quality control standards, and diverse product lines tailored to customer needs, particularly for use in transformers and environment-friendly vehicles. Additionally, it outlines key technical properties, testing standards, and product applications.

![23

Electrical Steel

1.8

1.7

2.5 3.0 3.5

B50(T)

High Induction

50PNA300 50PNA350 50PN400 50PN470

▲ △

▲

△

200

180

160

140

120

Hardness

(Hv1)

Punchability

Better

▲

△

Through higher induction and punchability, PNA-core features higher efficiency of products and longer

life of dies.

[High Efficient Refridgerator

Compressor Motor]

[High Efficient Aircon

Compressor Motor]

Typical Mechanical Property and Lamination Factor

Grade

0.50

(0.0197)

0.50

(0.0197)

0.50

(0.0197)

402

382

380

415

401

381

260

268

269

269

278

270

37

36

39

39

38

39

141

124

117

98.0

L C L C L C

Hardness

(Hv1)

Lamination

Factor

(%)

50PNA300

50PNA350

50PNA450

Note : 1. L : Specimens taken longitudinal to the rolling direction

C : Specimens taken transverse to the rolling direction

2. Specimens with C-6A coating are used for lamination factor test.

Thickness

mm (in.)

Tensile Stength

(N/mm2

)

Yield Point

(N/mm2

)

Elongation

(%)

Typical Electrical and Magnetic Property

Grade

50PNA300

50PNA350

50PNA450

Note : Above values are not guaranteed.

W15/50 indicates the core loss at the frequency of 50 Hz, magnetic flux density of 1.5T.

Tests were conducted in accordance with IEC60404-2 (or JIS C 2550-2000) method, after stress reliefannealing.

(Annealing condition : 750℃ (1380℉) × 2 Hr under neutral at mosphere.)

Core Loss

Watt per kilogram Watt per pound

W10/50 W15/50 W10/60 W15/60 W10/50 W15/50 W10/60 W15/60 B25 B50

0.50

(0.0197)

0.50

(0.0197)

0.50

(0.0197)

37

33

25

1.29

1.36

1.73

2.70

3.05

3.89

1.72

1.83

2.22

3.71

3.91

5.11

0.59

0.62

0.79

1.35

1.38

1.77

0.78

0.83

1.01

1.68

1.77

2.32

1.66

1.67

1.63

1.73

1.74

1.72

Thickn

ess

mm

(in.)

Density

(kg/dm3

)

Magnetic Flux

Density.Min

(T)

W15/50(W/kg)

Magnetic Property and Puncturbility Comparison (PNA-Core VS PN-Core)

전기강판영문내지최종1113 2010.11.13 2:27 PM 페이지23 g6](https://image.slidesharecdn.com/posco-crgo-240802144746-ae95ec5f/85/electrical-steel-process-manufacturing-POSCO-CRGO-23-320.jpg)

![26 www.posco.com

Types and Features of Surface Insulation

>> Surface Insulation

Inorganic

1.5~2.0

≥ 15

≥ 15

95.0

Not

recogniozed

Not

recogniozed

Not

recogniozed

-

-

-

- - excellent good excellent good Not

allowed

Curreent : 100~150A

Ar 99% flow10~20L/minSpeed

0.25~0.50mpm

ASTM A 717

SRA condition : 750°

C×2hrs. in DX rich gas

1.0MPa ± 0.05 in Pressure (JIS C 2550)

155℃×24hr in Air

750°

C×2hrs.

in DX rich gas

65 ℃, 95% humidity,

72 Hr

ISO 1519

ASTM D3359B

[0B (poor) ~ 5B

(excellent)] SRA:

R-134a/Freol @15C =

65g/100g

(130℃, 21day,0.45㎛

filter paper)

GO NO

Notice

Applied Spec

Composition

Thickness (um)

Resistivity

(Ωcm2/sheet)

Heat resistance

flaking after SRA

Weathering (powdering)

Adhesion

(mmФ)

Resistance

to

refrigerants

Weldability

Lamination Factor (%)

Note: 1) Please designate surface insulation according to usage. Regarding coating properties, please contact us.

2) The coating thickness value and the resistivity is typical value, not guaranteed.

General

Eco-

friendly

0A GS

General

C-6A

Eco-friendly

NS NM NT

C-9A

GO NO

Brfore SRA

After SRA

Brfore SRA

(Mandrel bend

tester)

30

Inorganic

1.5~2.0

≥ 15

≥ 15

95.0

Not

recogniozed

Not

recogniozed

Not

recogniozed

-

-

-

30

Inorganic

+organic

0.5~1.0

≥ 0.5

≥ 0.1

98.0

Not

recogniozed

Not

recogniozed

Not

recogniozed

5B

Not

recogniozed

Not

recogniozed

10

Inorganic

+organic

1.2~1.8

≥ 5.0

≥ 0.5

98.0

Not

recogniozed

Not

recogniozed

Not

recogniozed

5B

Not

recogniozed

Not

recogniozed

10

Inorganic

+organic

0.5~1.0

≥ 0.5

≥ 0.1

98.0

Not

recogniozed

Not

recogniozed

Not

recogniozed

5B

Not

recogniozed

Not

recogniozed

10

Inorganic

+organic

1.2~1.8

≥ 5.0

≥ 0.5

98.0

Not

recogniozed

Not

recogniozed

Not

recogniozed

5B

Not

recogniozed

Not

recogniozed

10

Inorganic

+organic

5.0~7.0

≥ 100

SRA Not Accepted

97.0

SRA Not

Accepted

SRA Not

Accepted

Not

recogniozed

5B

-

-

20

After

SRA(Cross cut

tester)

Change of

surface

Change of

weight

전기강판영문내지최종1113 2010.11.13 2:27 PM 페이지26 g6](https://image.slidesharecdn.com/posco-crgo-240802144746-ae95ec5f/85/electrical-steel-process-manufacturing-POSCO-CRGO-26-320.jpg)