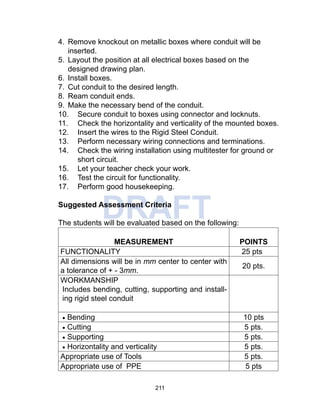

The document outlines a draft learner's material for Grade 10 focusing on Electrical Installation and Maintenance, published by the Department of Education in the Philippines. It emphasizes the assessment and development of personal entrepreneurial competencies (PECs) relevant to the electrical field, including the necessary skills and attributes of successful entrepreneurs. Additionally, the document includes instructional content, objectives, and activities aimed at enhancing students' understanding of entrepreneurship within the context of electrical installation.

![183

DRAFT

The GFCI protection requirement for commercial kitchens

was clarified by adding a definition of a kitchen. New requirement

expands the GFCI protection requirements for 15 or 20A,

125V receptacles to include receptacles located outdoors

that are accessible to the public. A new requirement expands

the GFCI protection requirements for the required 15 or 20A,

125V receptacle for heating, air-conditioning, and refrigeration

equipment [Article 210.63 of National Electrical Code series of

2005 p 54].

Since there have been at least three electrocutions reported

over a three-year period from boat hoists, a new subsection was

added. The rule specifies that GFCI protection is required for

“outlets” that supply boat hoists, not just “receptacle outlet.” This

will ensure GFCI protection regardless of whether the unit is cord-

and plug-connected or hard-wired.

The Philippine Electrical Code (PEC) requires that all

exposed metal on equipment and appliances be connected to

an equipment grounding conductor (Article 2.50). Under normal

circumstances, no current flows in the equipment grounding

conductor. The following example illustrates the purpose of the

equipment grounding conductor.

Figure 1: Show the schematic diagram of an appliance

without an equipment conductor connected to the metal chassis.

The appliance is sitting on a wood table, and therefore isolated

from earth ground. The appliance is “turned off”, but a wire

insulation fault has occurred before the switch. The chassis of

the appliance is at an electrical potential of 110 volts with respect

to ground. Since it is switched “off” and there is no path for fault

current to flow, no current flows in this circuit. Hence, the circuit

breaker will not trip, and the fault will go undetected.](https://image.slidesharecdn.com/electricalinstallationandmaintenancemodule10-190615094852-240724084137-2fe70a22/85/ELECTRICAL-INSTALLATION-AND-MAINTENANCE1-183-320.jpg)