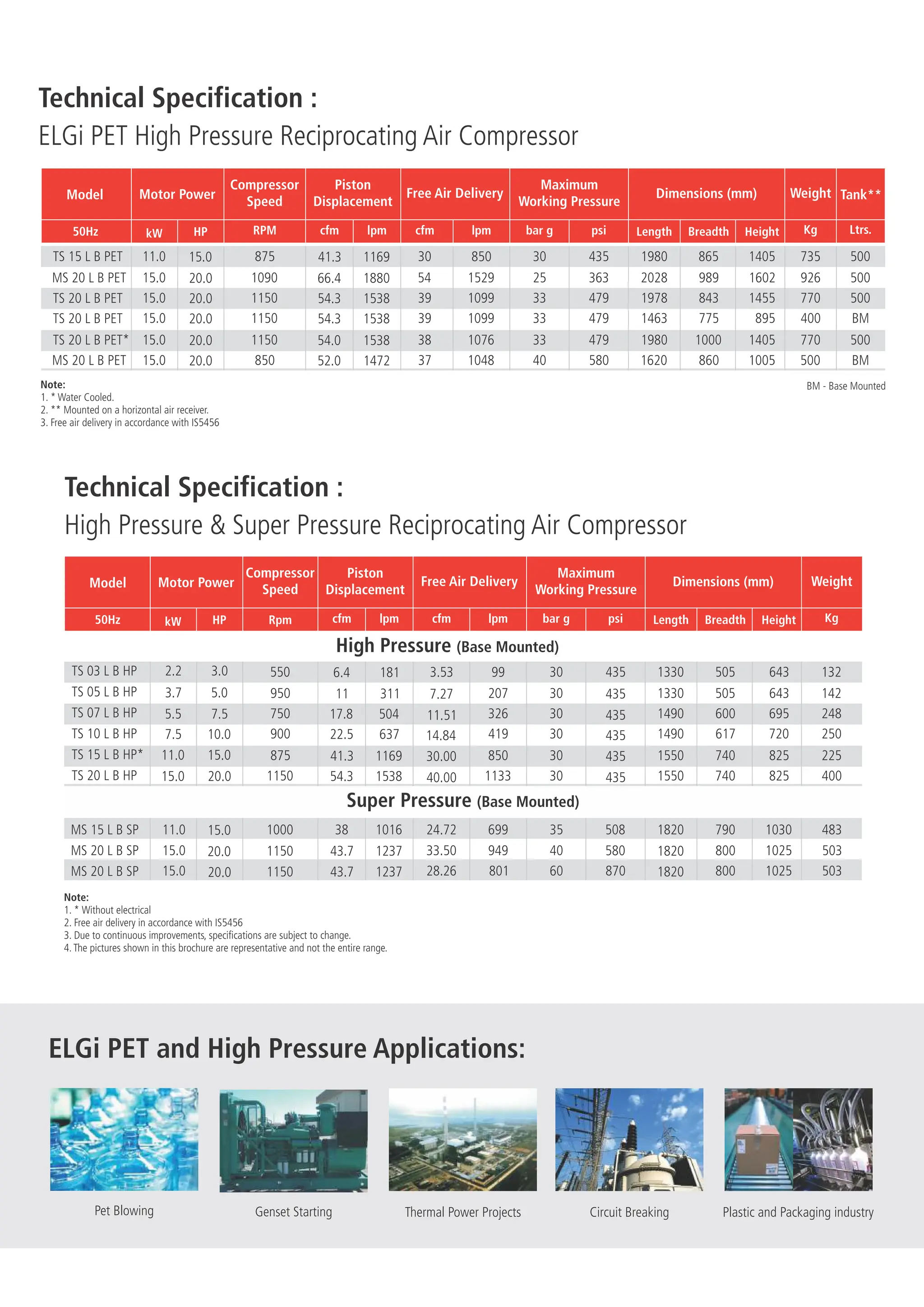

ELGi manufactures a diverse range of air compressors, particularly high-pressure reciprocating compressors, established in 1960 and known for their reliability and custom-engineered solutions. The company has extensive manufacturing capabilities and offers comprehensive after-sales support and parts availability, ensuring long-term customer satisfaction. ELGi’s products are widely used in various sectors such as packaging, plastic industries, and power plants, featuring innovative technology for enhanced performance and safety.