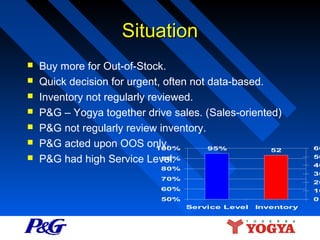

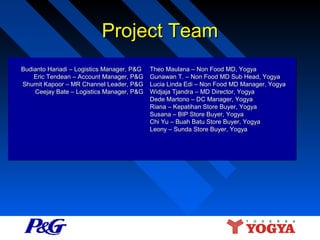

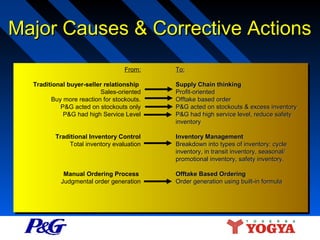

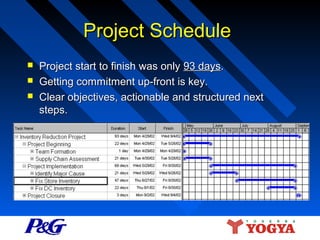

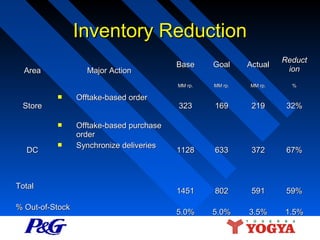

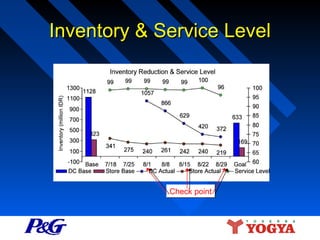

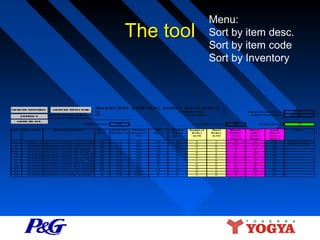

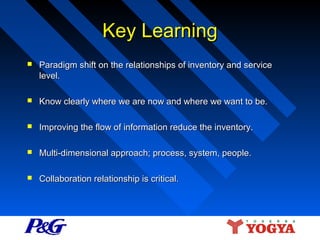

This document outlines an initiative between P&G and Toserba Yogya to reduce inventory levels. It describes the initial situation of high and unmanaged inventory levels driven by a sales-focused relationship. The objective was to reduce inventory by 650 million rupiah without impacting store service levels. Key actions taken included implementing offtake-based ordering, synchronizing deliveries, and developing an inventory tracking tool. These actions resulted in a 59% reduction in total inventory and an improvement in service levels. Key learnings included shifting from a sales paradigm to focusing on inventory and service level relationships, taking a multi-dimensional approach, and ensuring collaborative relationships.