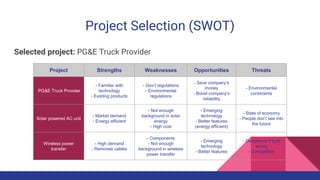

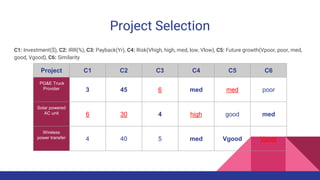

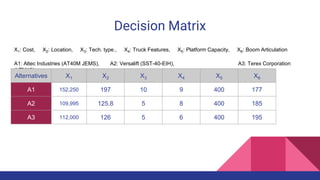

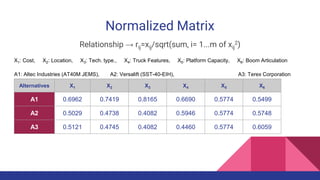

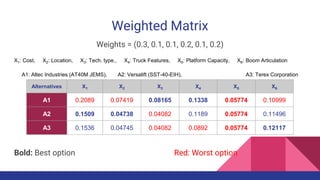

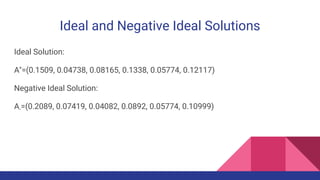

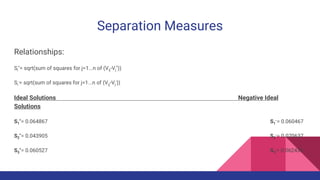

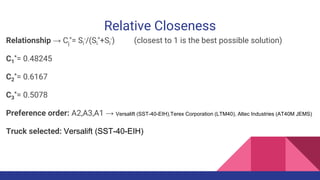

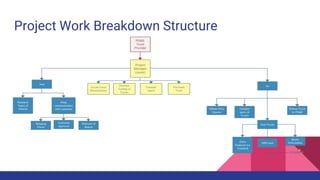

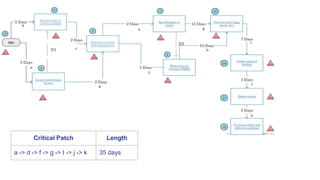

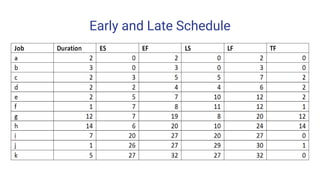

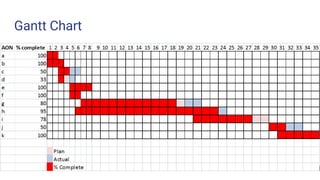

This document summarizes a project analyzing truck options for PG&E. The team used techniques learned in ECE 103 like SWOT analysis, decision matrices, and TOPSIS to select the best option. They analyzed trucks from Altec Industries, Versalift, and Terex Corporation. Using weighted criteria like cost, location, and features, TOPSIS identified the Versalift truck as the preferred option. It had similar capabilities to competitors at a lower price. Project planning tools like a work breakdown structure, time distribution, and Gantt chart were created to organize and complete the analysis.