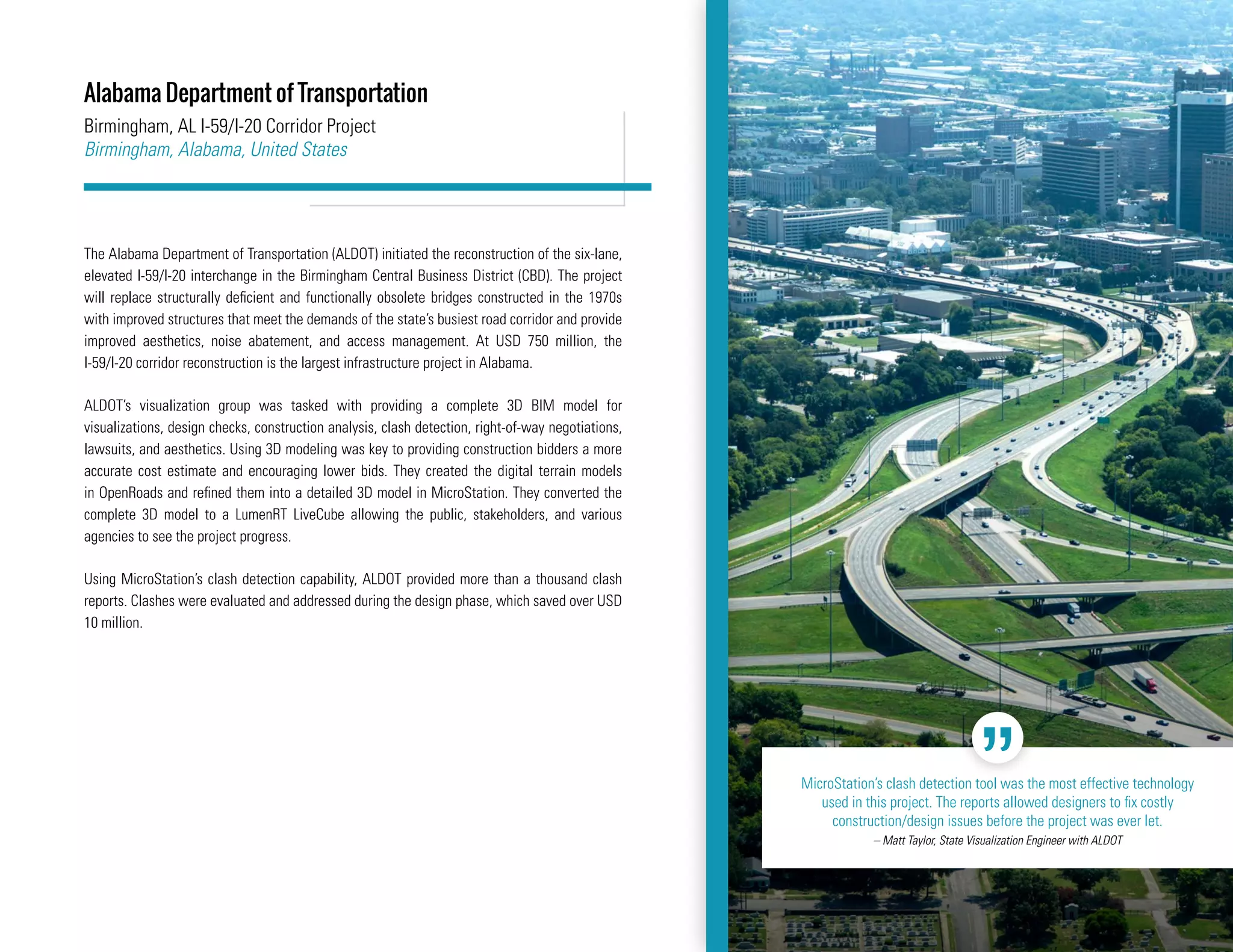

MicroStation software provides civil engineers with tools to improve design workflows and deliver projects more efficiently. It allows teams to incorporate various file formats, leverage multiple disciplines, and scale designs for both large and small projects. MicroStation also helps ensure quality deliverables are completed on time through integrated 3D modeling capabilities, real-world context, and automated output of plan sets and other documentation. Case studies demonstrate how MicroStation has helped civil engineering firms accelerate designs, reduce errors and costs, and improve collaboration across large project teams.