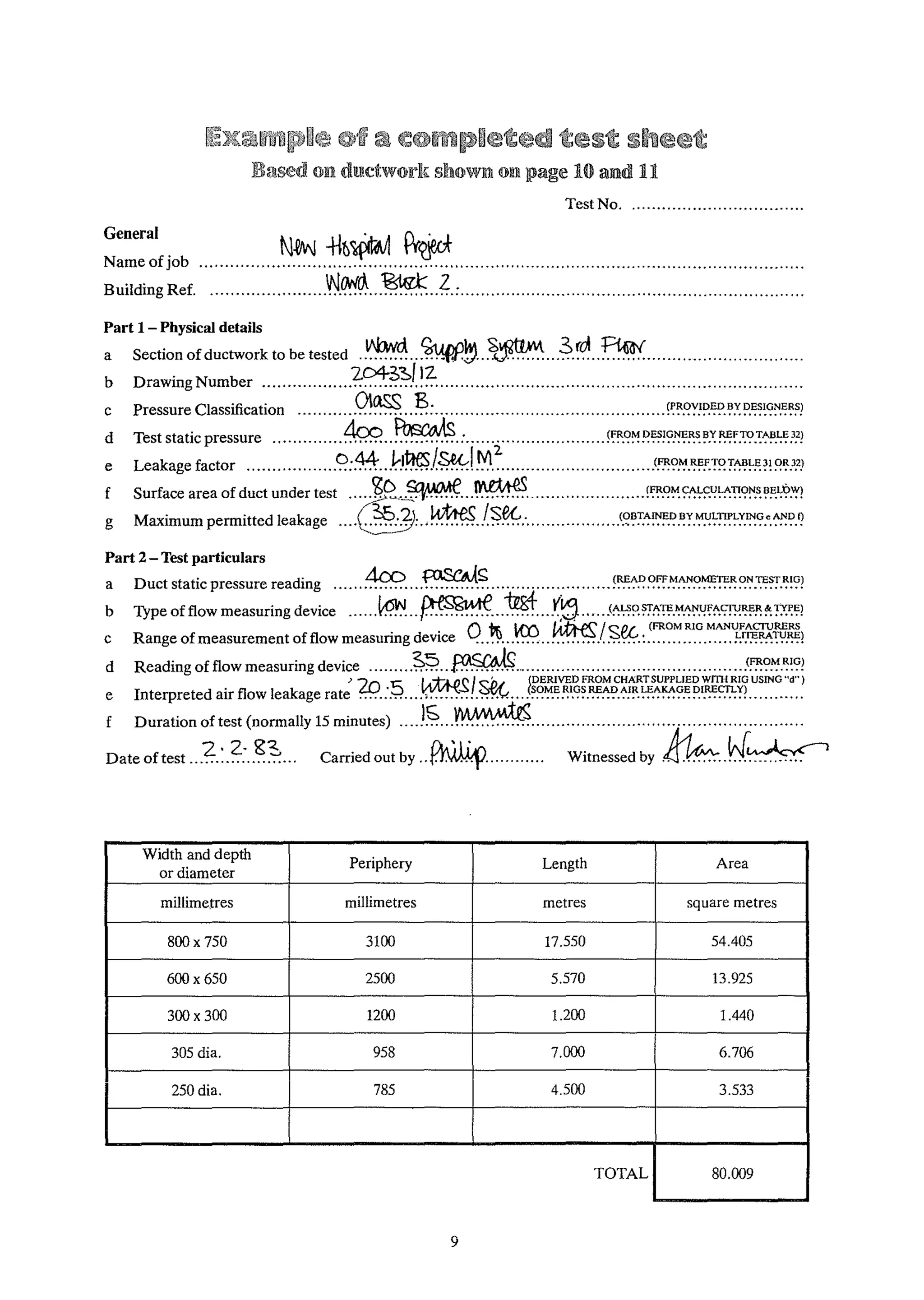

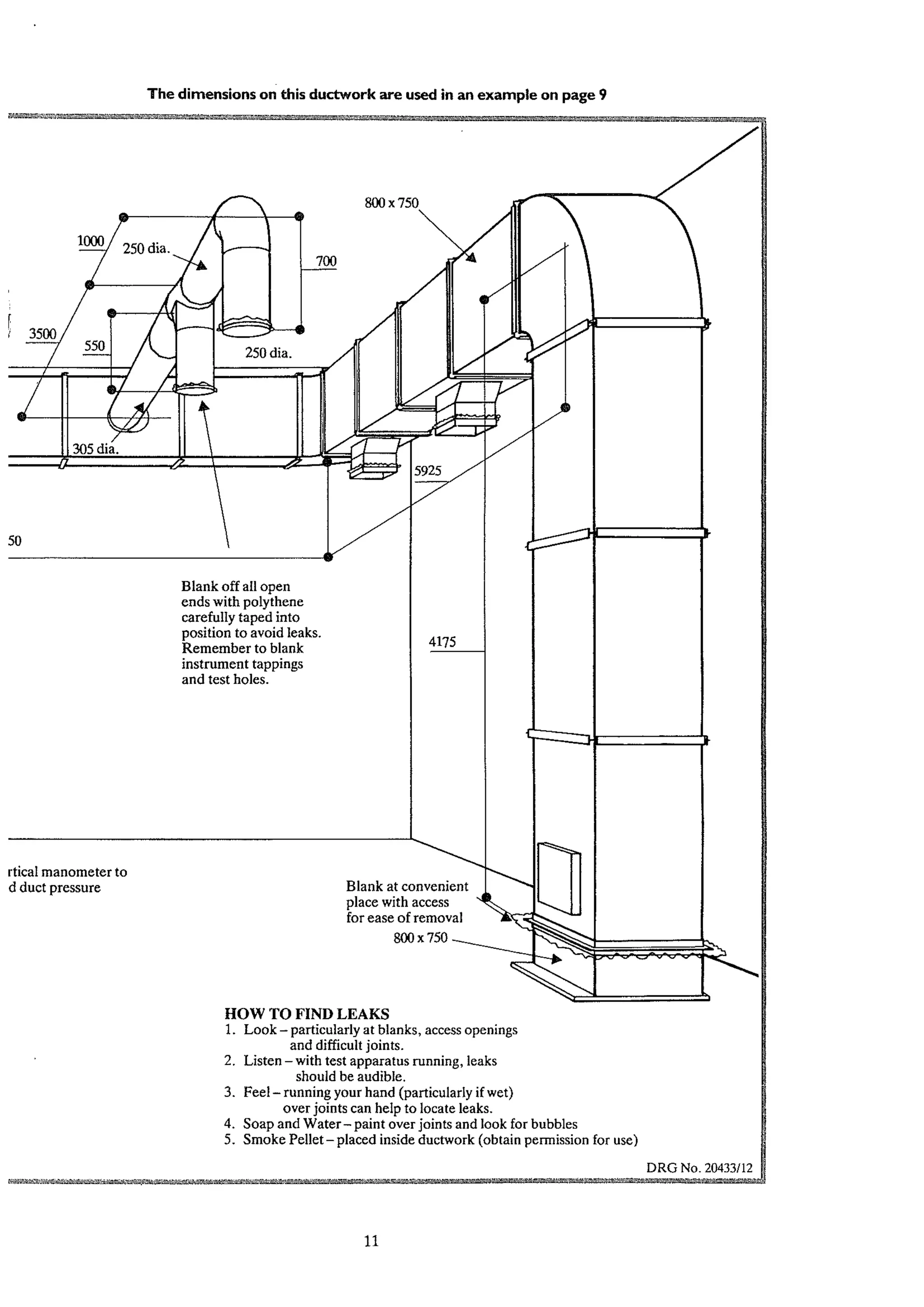

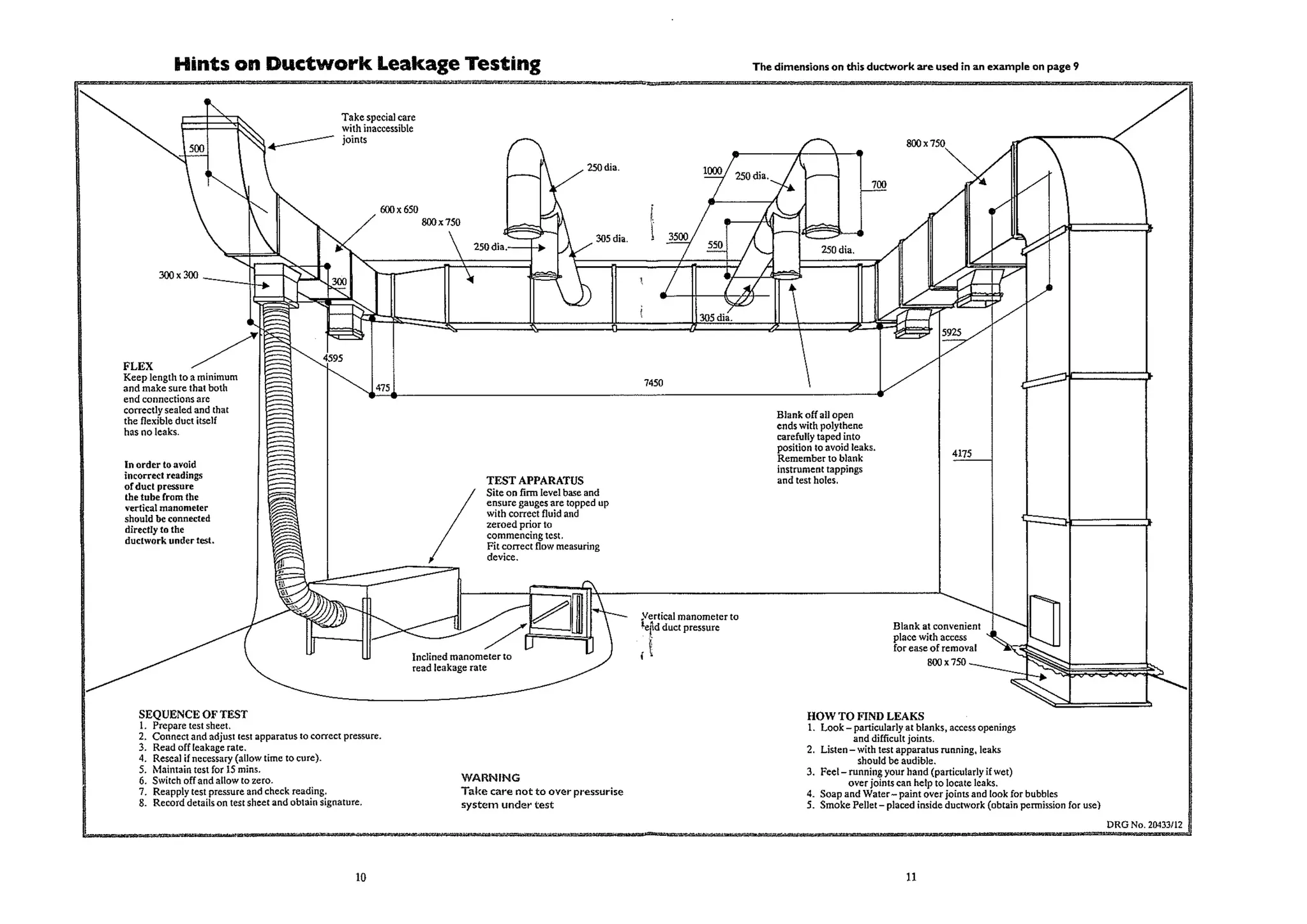

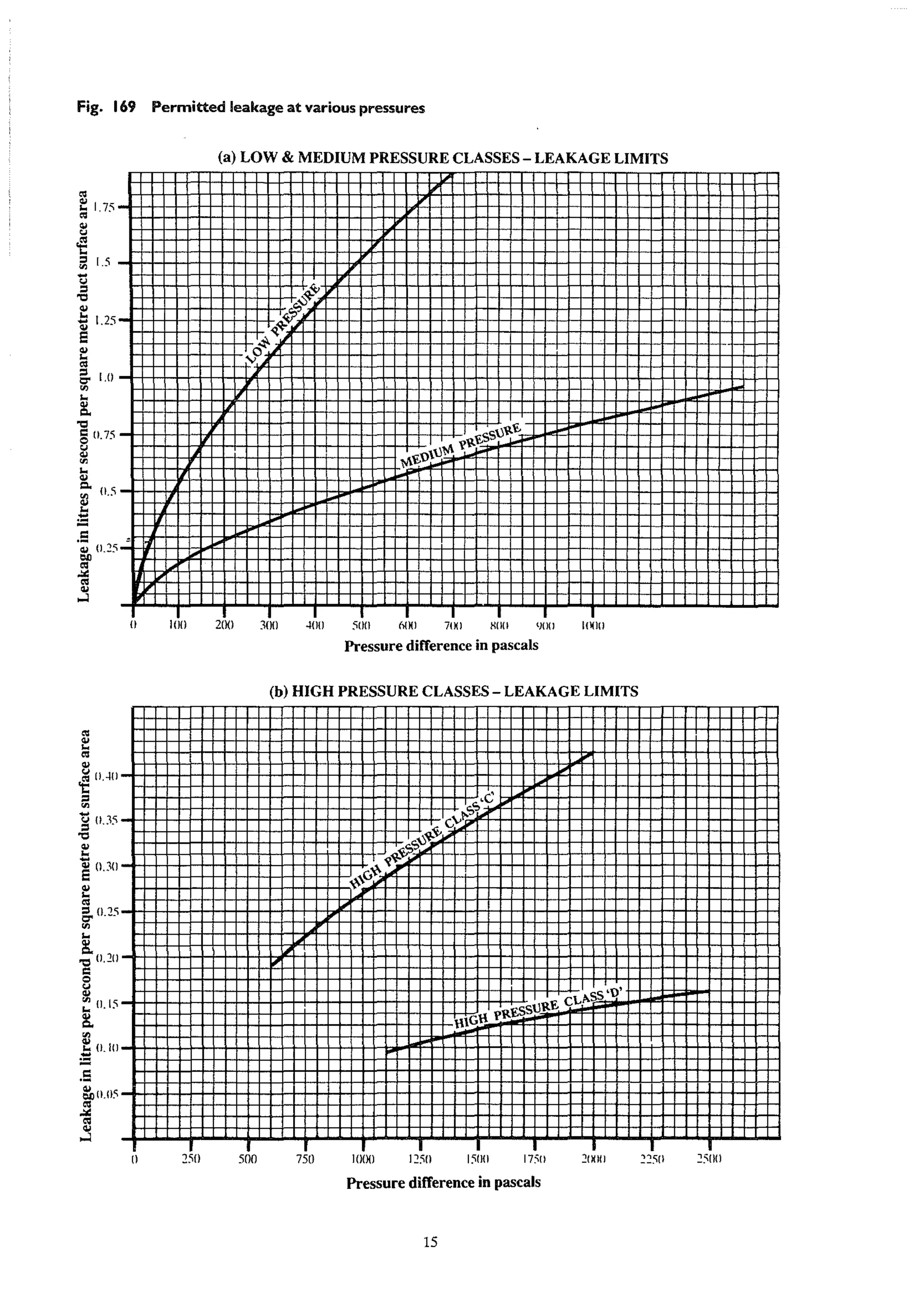

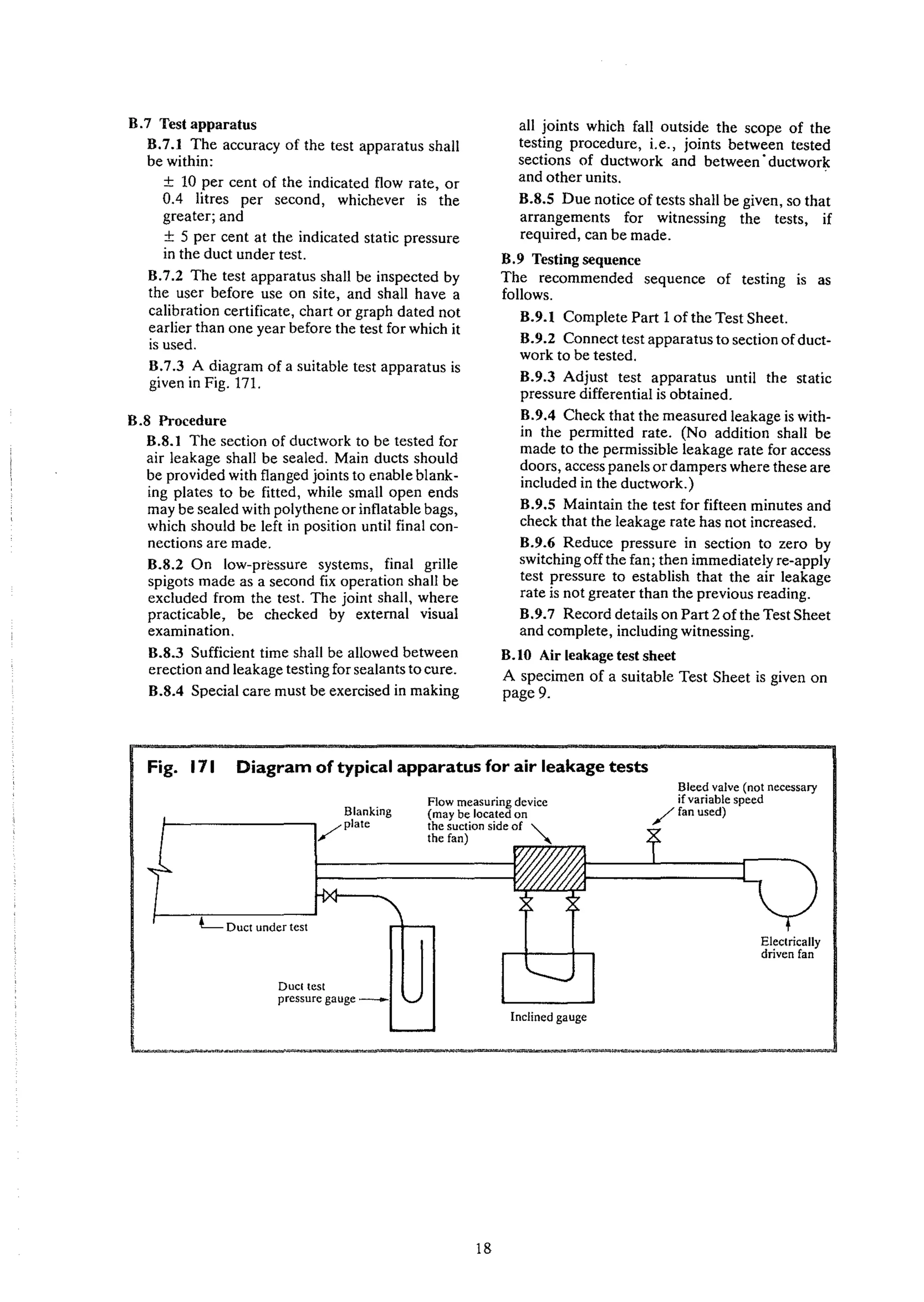

This document provides a guide to ductwork leakage testing based on the requirements of the DW/142 ductwork specification. It outlines the responsibilities of various parties in ensuring low ductwork leakage, including the drawing office in establishing test zones and limits, and the factory in proper sealing. The guide describes how to plan and conduct leakage tests by isolating ductwork into test sections, applying an air pressure, and measuring any air loss. If leakage exceeds limits, the guide advises locating and resealing any leaks before retesting.