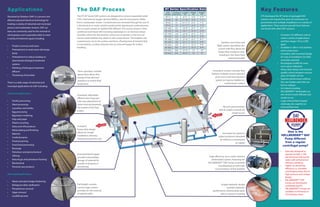

This document discusses dissolved air flotation (DAF) systems for treating industrial and municipal wastewater. DAF uses microscopic air bubbles to attach to contaminants like oils and suspended solids, floating them to the surface for removal. The document outlines ETS's turn-key DAF systems, which are simple and effective at removing various contaminants. It also lists their industrial and municipal applications and provides specifications for ETS's 14 standard DAF models.