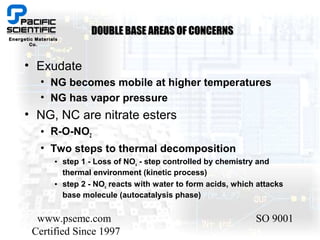

The document discusses the performance evaluation and failure investigation of the US Army M-796 and US Air Force BBU-35B impulse cartridges used in aircraft for ejecting countermeasures. It highlights the decomposition of double base propellant under specific temperature and altitude conditions, leading to inconsistent functioning of cartridges during qualification testing. The findings emphasize the importance of understanding the limitations of energetic materials and recommend design guidelines for propellants based on their thermal stability and performance characteristics.