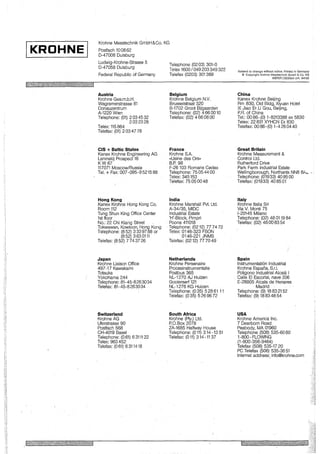

This document provides installation and operating instructions for various Krohne magnetic inductive flowmeters, including the IFM 2100 F, IFM 4100 F, IFM 5100 F, and IFM 9100 F models. It is divided into multiple parts that cover installation of the flowmeter and signal converter, programming and operation of the signal converter, special applications, functional checks, technical specifications, and other reference information. The instructions can be used to install the flowmeter in a pipeline, connect it to a signal converter, and have the system operational with just the information in Part A.

![& SeRarate-system fiowmeter as ordered

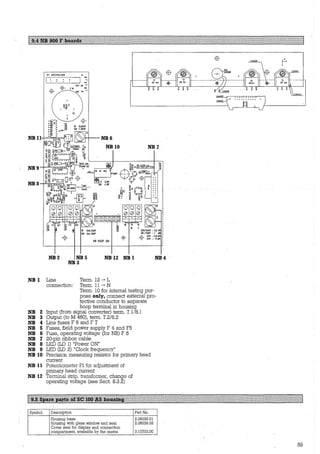

- SC 100 AS/F signal converter, field housing

- primary head with installation material according to the

• Installation and ORerating instructions with pl.:1#-out

condensed instructions for operation of the SC 100 AS/F

signal converter

following table/list

- signal cable (field current cable not supplied, tobe

provided by customer)

• Certificate of system calibration data

• ReROrl on factory setting of the signal converter

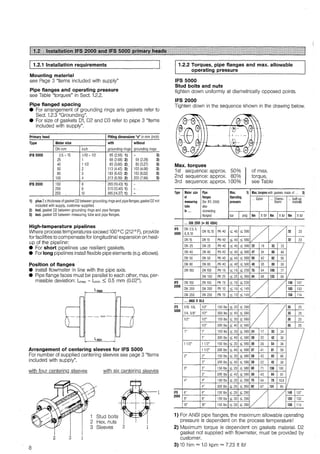

IFS 2000 and IFS 5000 Primary head

Primary head Supplied„. X=Standard O=Option Size of gaskets

Type Metersize Max. operating „.with „.with „.with grounding rings E „.wlo grounding rings

to."" pressure 1) centering stud bolts and gaskets but with gaskets 03 01, 02 + 03 in mm (inches) 3)

bar psig material

IFS 5000 :~]'!Jrr:.l2~Q1t{~S 4~q5f

ON 2.5, 4, 6, 10 40 580 2xrings 4xM12

ON 15 40 580 2xrings 4xM12

ON 25 40 580 2xrings 4xM12

ON 40 40 580 4xsleeves 4xM16

ON 50 40 580 4xsleeves 4xM16

ON 80 40 580 6xsleeves 8xM16

ON 100 16 230 6xsleeves 8xM16

25 360 6xsleeves 8xM20

IFS 2000 ON 150 16 230

/ /ON 200 10 145

ON250 10 145

IFS5000 ,.

.•. :ii":''~ec"''~'l

1/10, 1/8, 1/4, 3/8, 1/2" <20 <290 2xrings 4x1/2"

<40 <580 2xrings 4x1/2"

1" <20 <290 4xsleeves 4x1/2"

<40 <580 2xrings 4x5/8"

11/2" <20 <290 4xsleeves 4x1/2"

<40 <580 4xsleeves 4x3/4"

2" <20 <290 4xsleeves 4x5/8"

<40 <580 6xsleeves 8x5/8"

3" <20 <290 4xsleeves 4x5/8"

<40 <580 6xsleeves 8x3/4"

4" <20 <290 6xsleeves 8x5/8"

<25 <360 6xsleeves 8x3/4"

IFS 2000 6" <20 <290

1/1/8" <20 <290

10" <20 <290

1) With ANSI pipe flanges, the max. admissible operating pressure is

dependent on the product temperature

01

X

X

X

X

X

X

X

X

X

X

2) Gaskets 02 not supplied with flowmeter, tobe provided by customer!

01+02 and cable V da di

/ ~

01 are special 0-rings

01 are special 0-rings

0 X 46 (1.81) 26 (1.02)

0 X 62 (2.44) 39 (1.54)

0 X 74 (2.91) 51 (2.01)

0 X 106(4.17) 80 (3.15)

0 X 133 (5.24) 101 (3.98)

0 X 133 (5.24) 101 (3.98)

/ /

01 are special 0-rings

01 are special 0-rings

01 are special 0-rings

1/~

01 are special 0-rings

01 are special 0-rings

0 X 46 (1.81) 26 (1.02)

0 X 46 (1.81) 26 (1.02)

0 X 62 (2.44) 39 (1.54)

0 X 62 (2.44) 39 (1.54)

0 X 74 (2.91) 51 (2.01)

0 X 74 (2.91) 51 (2.01)

0 X 106 (4.17) 80 (3.15)

0 X 106 (4.17) 80 (3.15)

0 X 133 (5.24) 101 (3.98)

0 X 133 (5.24) 101 (3.98)

1//

01 are special 0-rings

01 are special 0-rings

01 are special 0-rings

3) da = outside diameter

di = inside diameter -

s = thickness of supplied gaskets

For arrangements of gaskets 01, 02 and 03 see "grounding diagrams" in Sect.1.2.3!

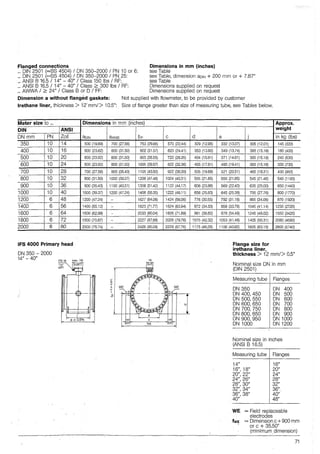

IFS 4000 and M 900 Primary heads

- lnterconnecting cables V, see grounding diagrams in Sect. 1.3.11

- Grounding.J:l.o.gs E (option), if ordered.

Supplied without installation material (stud bolts, gaskets),_to be customer supplied!

s

2)

2)

1.6 (0.06)

1.6 (0.06)

1.6 (0.06)

1.6 (0.06)

1.6 (0.06)

1.6 (0.06)

~)

2)

2)

2)

2)

1.6 (0.06)

1.6 (0.06)

1.6(0.06)

1.6 (0.06)

1.6(0.06)

1.6 (0.06)

1.6(0.06)

1.6 (0.06)

1.6 (0.06)

1.6(0.06)

2)

2)

2)

3](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-3-320.jpg)

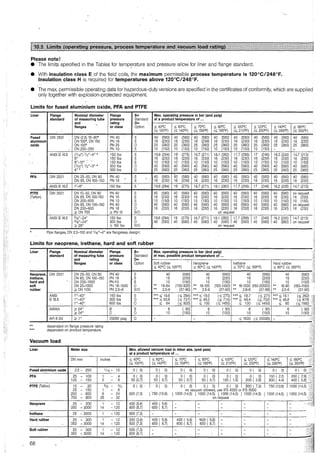

![/ 1.3.1 Neoprnne and hard-rnbber liners

Note temperature limits

e Storage: - 20 to + 60 °C (- 4 to + 140 °F),

keep immobile

• Transport: - 5 to + 50 °C (+ 23 to + 122 °F)

• Process: Neoprene - 20 to + 60 °C (- 4 to + 140 °F)

Hard rubber - 20 to + 90 °C (- 4to+194 °F)

[Temperatures below - 5 °C (+ 23 °F) are only permiss-

ible if the pipe run is supported an both sides oftheflow-

meter, and providing there is only slight vibration and no

water hammer in the pipe.]

Gaskets are necessary for hard-rubber liners, e.g. Neoprene

or soft-rubber gaskets.

Max. torques: see Sect. 1.3.10, Column B

/ 1.3.2 PTFE liner

lnstall to avoid an excessive vacuum condition at the meter.

The PTFE liner is formed around the ends of the flanges,

do not remove or damage.

The flanges are factory-fitted with special protection covers.

Do not remove these until just before installation. Replace by

pieces of smooth sheetmetal [0.3 to 0.6 mm (0.012" to 0.024")

thick] when fitting the flowmeter between the pipe flanges (to

be removed after installation).

Attached protective rings can optionally be supplied, in

which case the above-mentioned sheet metal pieces are not

required. These protective rings can simultaneously be used

as grounding rings, see Sect. 1.3.7.

Max. torques: see Sect. 1.3.10, Column A.

/ 1.3.3 lrethane liner

lmportant for IFS 4000 primary head with irethane liner,

> 12 mm I > 0.47" thick:

The flange connections are !arger than the diameter of the

measuring tube! Use pipe flanges according to the following

tables.

Meter size ON in mm Meter size in inches

Measuring Flanges Measuring

tube tube

ON 350 ON 400 14"

ON 400, 450 ON 500 16", 18"

ON 500, 550 ON 600 20", 22"

ON 600, 650 ON 700 24", 26"

ON 700, 750 ON 800 28", 30"

ON 800, 850 ON 900 32", 34"

ON 900, 950 ON 1000 36'', 38"

ON 1000 ON 1200 40"

Max. torques (according to size of flanges!):

see Sect. 1.3.10, Column B

l 1.3.4 M 900 with sanitary connections

Versions

Flanges

16"

20"

24"

28"

32"

36"

40"

48"

e Sanitary pipe union to DIN 11851, ON 10 to 125

e Clamp connection, measuring tube 1" to 4"

Dimensions

Refer to Section 10.6.3

Cleaning the measuring tube

by CIP (cleaning in place) using various chemicals, acids,

alkalis, steam or water up to 140°C (284°F).

Installation

To prevent damage to the PTFE liner, the factory-supplied

rubber gaskets must be fitted without fail.

Grounding, refer to Section 1.3.11.

10

J 1.3.5 M 900 Hj with heating jacket

8 M 900 HJ primary heads with heating jacket are available

for ON 10 to 100 or 3/s" to 4" meter sizes (for dimensions

see Sect. 10.6.3).

e The two connecting flanges for the heating jacket are

designed to DIN 2501, ON 15, PN 40 or to ANSI, 1f2",

150 lbs.

e Max. operating pressure of heating medium:

10 bar /150 psig.

e The maximum permissible temperature of the heating

medium, in liquid or vapor state, is governed bythe insula-

tion class of the field coils (E up to 120°C / 248° F, H up to

180° C / 356 ° F) and the liner used for the measuring tube.

Refer to Sect. 10.5 for max. permissible operating data.

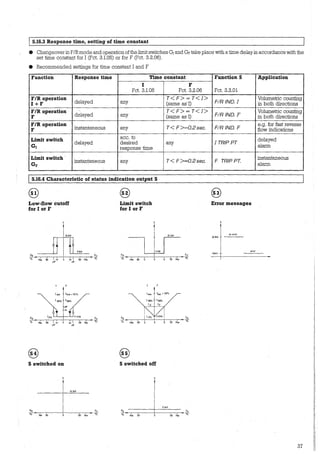

1.3.6 Pipelines with cathodic protection

For installation and grounding, refer to Sect. 6.5.

1.3.7 Grounding rings I Protective rings

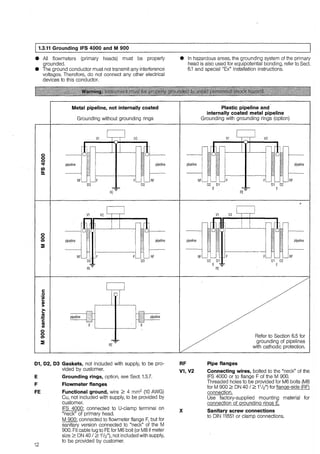

8 Required in conjunction with plastic or internally coated

pipes.

e Grounding rings form a conductive connection with (he

fluid. ·

e Material CrNi steel 1.4571 or SS 316 Ti-AIS!, others on

request.

8 For grounding and connection of the grounding rings,

refer to Sect. 1.3.11.

1

2

3

Grounding ring No. 1,

3 mm/ 0.12" thick.

Grounding/protective

ring No. 2

for primary heads with

PTFE liner, fitted to the

flanges, 3 mm I 0.12" thick.

Grounding/protective

ring No. 3

with cylindi-ical neck,

to protect

the liner of the flowmeter

particularly at the

inlet edge in conjunction

with abrasive fluids.

- Length 30 mm for

ON 10 to 300 or

3/s" to 12".

- Length 100 mm for

2:: ON 350 or ;::::: 14".](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-10-320.jpg)

![f:l:l~~·!lll1~1~111f~1lll~lllllllll!ll.!·:lllllll.l:lll!.=l!l1.:l:l!l:::lil.!:::I

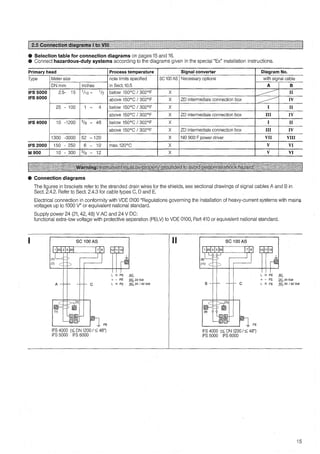

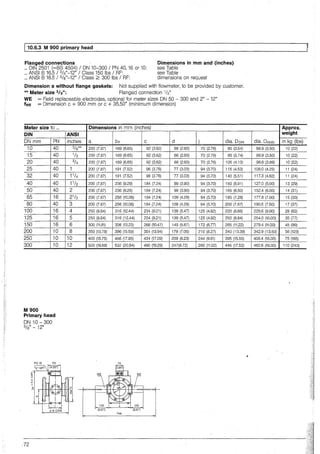

0 Electrical connection in conformity with VDE 0100

"Regulations governing heavy-current installations with rated voltages up to

1000 V" or equivalent national standard. Refer to connection diagrarns,

Seel. 2.5, for power connection to signal converter (and power driver, if pro-

vided).

e Do not cross or loop the cables in the terminal boxes of the primary head,

signal converter and power driver, if supplied. Use separate PG or NPT

screwed conduit entries for each cable~

O Special regulations apply to installation in hazardous areas. Referto Seel. 6.1

and special "Ex" installation instructions.

O On normal customer orders, the GK (primary constant) of the signal converter

is factory-setto match that ofthe primary head with which it is ordered. The GK

is engraved on the primary head nameplate and also shown on the converter

nameplate. These instruments should be installed together, otherwise

the converter will need to be reset (see Seel. 4.6 and 8.2, Fct. 1.04, 1.05 and

4.07).

fäi@l§.i.it~iliU~ifüii~fümli@itIIHIIlHHittIIItIIt11lt1IHl

e Do not expose signal converter (or power driver) and switch gear cubicle(s)

with installed units to direct sunlight. lnstall a sunshade, if necessary.

e Do not expose to intense vibration.

e Ensure adequate cooling of SC 100 AS/F unit(s) when installed in switchgear

cubicle(s), e.g. use heat exchangers.

• lnstall signal converter as close as possible to the primary head.

e Use factory-supplied standard signal cable A (type DS), standard length 10 m

(30 ft). For langer lengths and bootstrap signal cable 8 (type 8TS), refer to

Sect. 2.5.2 and 2.5.3.

e Always use the bootstrap signal cable 8 (type 8TS) for IFS 5000 primary

heads, DN 2.5 -15 OM' - %"), and in conjunction with contaminated fluids

having a tendency to form electrically insulating deposits.

!liliii::mi~MmiM~::;::@~'=«lifl1ftllitifl:::i[fü1Iiti1l

e Noteinformation given in Sect. 2.1!

• Note the information given on the instrument

nameplates on the primary head, signal converter

(voltage, frequency)!

e Power supply 24/42 Volt AC and 24 Volt DC,

functional extra-low voltage with protective separa-

tion (PELV) to VDE 0100, Part 410, or equivalent

national standards.

0 Power supplyforthe primary head via the signal con-

verter (or power driver, if applicable).

e Connection diagrams refer to Section 2.6.

e Line resistance for 24 V DC and 24/42 V AC

max. internal resistance Rmax of voltage supply

(transformer or DC voltage source and cable)

24 Volt DC / 24 Volt AC: Rmax 24 s 1 ohm

42 Volt AC: Rmax 42 s 2 ohms

max. length Lmax of power cable

Lmax = 28 X A (Rmax-R;)

A Cross-section of power cable in mm2

copper wire.

Rmax Interna! resistance of voltage supply

Rmax 24 or Rmax 42, see above

R; Interna! resistance of transformer or

DC voltage source

Example:

42 V AC / A = 1.5 mm2

/ R; = 0.2 ohm !

Rmax 42 = 2 ohms

Lmax = [28 x 1.5 (2-0.2)] = 75.6 m

75.6 m X 3.3 j!_ ::::: 250 fl

m

•.

Connection of several signal converters to 1 transformer

(n = number of converters)

Separate power cable: R; increases by factor "n" (R; xn)

Common power cable: Lmax decreases by factor "n"

(Lma/n)

!llliMHfli'-!llliiiI:'-i!ilMii#.r:li!i~J.illE~5,lIIf1IIl1ltlII11Hl1HIIfü111Il11I1Hll11tIIl1tllittitlt1Il11I111III1Hf1ttll

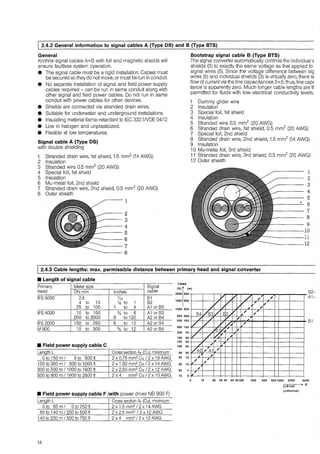

2.4.1 Abbreviations used and important information to Sect. 2.4

A Signal cable A (type OS) with double shielding; for max. length (Lmaxl see Diagram: cuNes A1 and A2

8 Signal cable 8 (type 8TS) with triple shielding; for max. length (Lmaxl see Diagram: cuNes 81, 82, 83 and 84

C Field power supply cable; for minimum cross-section (AF) and length see Table

D High-temperature silicone cable, 3 x 1.5 mm2

Cu / 3 x AWG 14, with single shielding, max. 5 m / 16 ft length

E High-temperature silicone cable, 2x1.5 mm2

Cu/ 2 x AWG 14, max. 5 m / 16 ft length

F Field power supply cable, connection between IFS 4000 primary head (ON ;;::: 1300 / ;;::: 52") and power driver;

see Table for minimum cross-section (AF) and max. length

G Gable connecting power driver and signal converter, min. cross-section 2 x 0.5 mm2 Cu / 2 x 20 AWG,

max. length 300 m (1000 ft)

AF Cross-section of field power supply cables C and F in mm2

(AWG) Cu, see Tables

L Length of cable

x Electric conductivity

ZD lntermediate connection box, required in conjunction with cables D and Efor IFS 5000 and IFS 4000 primary heads where process tem pera-

tures exceed 150°C (302°F)

• Determining the maximum permissible distance between primary head and signal converter

1. The length of signal cableA or Bis dependenton the electric conductivityx ofthe liquid product, and also on the type and meter size

of the primary head; see Table and Diagram "length of signal cable".

2. The length offield power supply cables C and Fis determined bythe cable cross-section AF; see Tables "field power supply cable C

and F".

3. The shortest cable length obtained either according to Point 1 or Point 2, is the maximum permissible distance between primary

head and signal converter!

e Special regulations apply to hazardous-area operation; refer to Sect. 6.1 and special "Ex" installation instructions.

• Always use the bootstrap signal cable B (type 8TS) for IFS 5000 primary heads, DN 2.5to15 (1

'1o"to 1

12") andin conjunction with contami-

nated fluids having a tendency to form electrically insulating deposits.

13](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-13-320.jpg)

![[:?:~~!!l§iiii~fIIItIIIIIIIIIIIItII!IIIItIIIIIIIIfIIIIfIIIIIIIIIIIft!tIIflftIIIIIIIttillIIIIIIfII:IIlIIIIII!

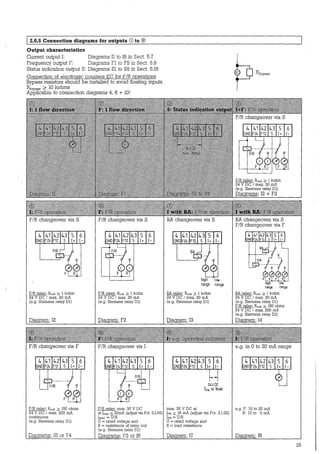

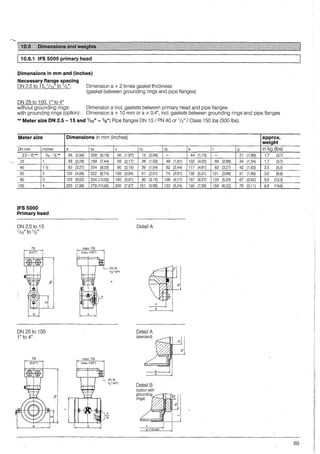

J 2.6.1 Abbreviations used for outputs

Abbreviation Stands for Programming

via Fct.No. ..........

BA Automatie range change 3.3.01 + 3.3.02

EC Electronic counter -

EMC Electro-mechanical counter -

F Frequency (pulse) output 3.2.01 et seq.

F100% Pulses for O = 100% flowrate or 3.2.02 + 3.2.03

pulse value 3.2.02 + 3.2.04

Fmax Pulses at O higher than 100% flow -

(max. 115% of F10o%)

GF Trip point for frequency output 3.3.01 + 3.3.04

G1 Trip point for current output 3.3.01 + 3.3.03

1 Current (analog) output 3.1.01 et seq.

Io% Current at O = 0% flow 3.1.02

1100% Current at O = 100% flow 3.1.03

lrnax Current at O = over 100% flow 3.1.04

Oo% 0% flowrate -

0100% Full-scale range, 100% flowrate F:l.01 / R:l.02 + 1.03

Ornax Max. flow, O greater than 100%, -

corresponding to lmax + Fmax

s Status indication output 3.3.01 et seq.

SMU Low-flow cutoff for 1 + F 1:3.1.06 / F:3.2.07

SMU-1 Low-flow cutoff 1/ on value 3.1.07

off value 3.1.08

SMU-F Low-flow cutoff F / on value 3.2.08

off value 3.2.09

F/R Forward/reverse flow -

J 2.6.2 Current (analog) output 1

e Current output is galvanically isolated, see block diagram in Sect. 12.

• All functions and operating data are programmable, see Sect. 4 + 5.7.

Description

see Sect. „„„„„„••„.

5.17

5.8

5.8

5.8

5.8

5.8

5.8

5.18

5.18

5.7

5.7

5.7

5.7

5.3 (5.7 + 5.8)

5.3 (5.7 + 5.8)

5.3 (5.7 + 5.8)

5.16

„

5.9

5.9

5.9

5.9

5.9

5.10

• Factory-set data and functions are listed in the enclosed report on settings. This can also be used to record any

changes made to the operating parameters.

• Max. load at terminals 5/6 for hooo,,u (Fct. 3.1.03):

max. load in kohms =

20V

(e.g. 1 kohm for Iioo% = 20 mA)

1100% [mA]

• Time constant 1, adjustable between 0.2 and 3600 seconds (Fct. 3.1.05), refer to Sect. 5.7.

e Automatie range change BA, ratio 1:20 to 1:1.25 (corresponding to 5 to 80% of 0100%), adjustable in 1% increments

(Fct. 3.3.01+3.3.02), see Sect. 5.17. Changeover occurs from high to low range at approx. 85% of the low range, and from

low to high range at approx. 98% of the low range. Operative range displayed by status indication output S.

e Low-flow cutoffSMU-1, adjustable independently ofSMU-F (frequency output). Cutoff "on" value between 1and 19% of

Owo% (Fct. 3.1.06 + 3.1.07), cutoff "off" value from 2 to 20% of 0100% (Fct. 3.1.06 + 3.1.08), refer to Sect. 5.9.

e Trip point Gh adjustable between 1 and 110% of 0100% (Fct. 3.3.01 + 3.3.03). Status indication output S shows when trip

point exceeded, refer to Sect. 5.18. Trip point G1 has a delayed action equal to the time constant of current output I.

e Connection diagrams 1, 4, 5, 7, 8, 9, 10, 11 + 12, refer to Sect. 2.6.5.

17](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-17-320.jpg)

![Part B Signal converter SC 100 AS

This Section 4 is repeated in the form of pull-out condensed operating instructions between pages 42 and 43.

!M~!t§i#i'.fü~$fi~it~fil@i.)~QS.M#ilf1fllIIIIIIflf1lIIlIIffIItttlfiffffffIIIlIIIIffällt1ItIIIItittitltifU

J--1~----+•

~JL_Q_b__&.__,

MAGNET (OPTION)

-, r o 1

i: 0 J. 1

rn=:l/hr

1 1 1

SC100AS]

+----?--+--<2

iL~

~

Q ENTER Ü QENTERÜ

1 ill]::::::[IIJ 1

t:m::~Ij::[IIJ

u

ALTERN.

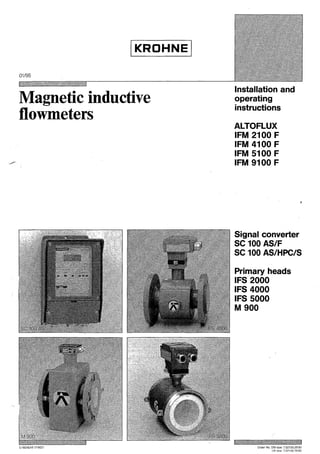

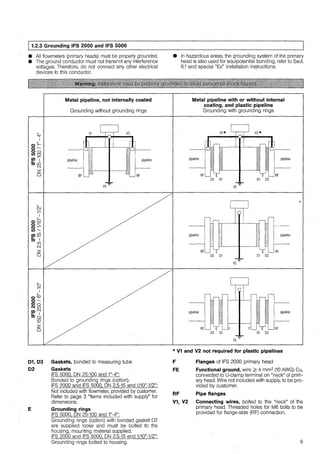

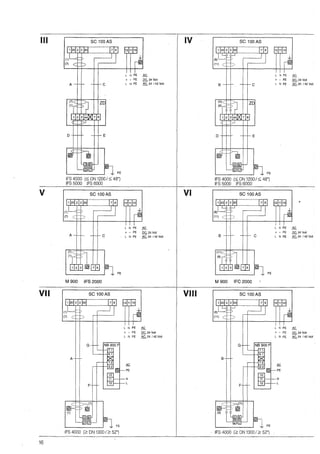

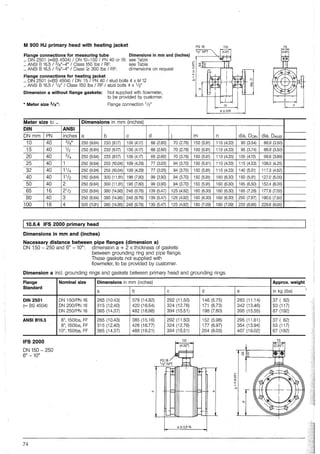

1 4.2.1 Menu levels

NORMAL

IF-TEST

CD Display, lst line

® Display, 2nd line

® Display, 3rd line,

cursor symbols described below:

Q Actual flowrate

+

Status indication output S

active (= 24 V)

Totalizer (Forward flow)

Totalizer (Reverse flow)

Surn totalizer (+ and - )

Low-flow cutoff SMU for

current and/or frequency

output (I/F) "in function"

@ Keys for programming the signal converter, refer to

Sect. 4.3 for function of keys.

@ Magnetic sensors (option) to program the converterby

means of a hand-held bar magnet without having to

open the housing, refer to Sect. 6.3. Function ofsensor'8

same as keys @. Hold the bar rnagnet by the black rub-

ber cap. Apply blue end of the magnet (north pole) to

the glass pane above the magnetic sensors. Sensor

response acknowledged by symbols appearing in lst

line of display.

® Plug connector

(J) Plug-in jurnper positi.ons to check field power supply,

refer to Sect. 7. 1.

The program for the signal converter consists of 5 levels. The Fct.No. in the lst line (bottorn line) of the display will identify

the menu level during prograrnming. ·

Measuring 1 Actual display

mode level

1 Err. E 01- E 16 1 Err. P 01 - P 14 1 1 TOT. RESET

Reset

totalizer

Mainmenu

level

Submenu

level

Function

level

Data level

Measuring mode Error in Error in

(see Sect. 4.3)

1

program plausibility check

(see Sect. 4.4) (see Sect. 4.5)

1 1

r----------~ 1

1 1--------------------~

1 1

T T

Fct. 1.00 Fct. 2.00 Fct. 3.00

Display Outputs

1---------------i Fct. 4.00

Special fct.

Fct. 1.01-

1.07

Data changes acc. to Table in Sect. 4.6 possible only on this level!

21](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-21-320.jpg)

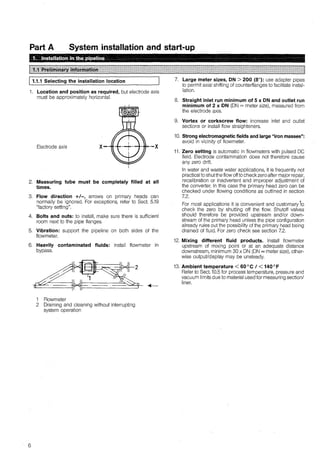

![1 4.2.2 Programming chart Table of functions, see Sect. 4.6

Fct. 4.02: with coding (YESJ

Measurin:g mode

Entry into tprogramming '------1•-----l]•----11•,.___ ___,

mode, see Sect.

5.12

Fct. 1.00

FLOW DATA

Fct. 1.00

FLOW DATA

Fct. 4.02: without coding (NOJ

Fct. 2.00

DISPLAY

Fct. 2.00

DISPLAY

Fct. 3.00

OUTPUTS

Fct. 3.1.00

CUR.DUTP. I

r------;

,_ _______.

Fct. 3.1.00

GUR. OUTP. I

Fct. 3.00

OUTPUTS

Err.E01-E16 _____ ._ _____ ~

-..... Error in meas. mode, see E-List, Sect. 4.4 C!ear

-..... error

Display next error, message tErr. E02-E16 ifmore

··~ ,„ r_·- Terminate error output

1

Fct. 3.2.00

FRE OUTP. F

Fct. 3.2.01 -

3.2.09

Fct. 3:2.01 -

3.2.09

Fct. 3.2.00

FRE OUTP. F

Fct. 3.3.00

/ND. OUTP. S

Fct. 3.3.01 -

3.3.04

Fct. 3.3.00

!NO. OUTP. S

Measuring mode 1-------~-----___,

Plausibility-

check

,_______, Err. P01 - P14 Err. P02 - P14 1--------

Error detected by plau- '. Display next

sibility check, see P-List error, if more

Sect. 4.5 than one

Reset totalizer, see Sect. 5.6

Measuring mode 1---~---L oa--------1Measuring mode

22](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-22-320.jpg)

![Fct. 1.00

FLOW DATA

1Measuring mode 1

1

4.2.3 Description of keys

O 1 Measuring mode level

Enter programming mode

Display errors

Clear error messages

See left for function of keys

Important

applies to all menu levels

1. Continuously pressing C or [] keys will

cause their function to be continuously

repeated (auto-repeat function).

2. If no keystrokes made within approx.

180 sec, signal converter reverts autom.

to meas. mode without accepting any

changed data into meas. prog. (time-out

function). Exception: if at start of

"----+------------------1 programming Err. E04, E05 and/or E14

established, see Sect. 4.4.

Fct. 4.00

SPEC. FCT.

Fct. 4.01 -

4.10

Fct. 4.01 -

4.10

Fct. 4.00

SPEC. FCT.

..-- Terminate error output and revert

to main menu level,

lst·main menu displayed

Fct. 1.00

FLOW DATA

Correct faulty fanction(s)

and data

f) 1 Main menu level

[] Select main menu

C Enter main menu displayed

[j [j [j Revert to measuring mode level, see @

01 Suhmenu level

[] Select menu

C Enter submenu displayed

[j Revert to main menu level, see 0

0 1 Function level

[] Select function

C Enter function displayed,

continue as under 0

"Data level"

[j Return to main menu or

submenu level

01 Submenu level

[j Revert to main menu level

[] Select submenu

C Enter submenu displayed

@ 1 Main menu level

Data/Units

[] Select next

proposal

C Return to

Fct. level,

retain

previous

data/units

Numerical values

Increase flashing digit

(cursor) by 1

Shift flashing digit

1 place to right.

Note: if in last

position, system

reverts to Fct.

level, last numerical

value retained!

Return to Fct. level, store new data

temporarily. Note: display

"Err. 0000 < MIN" or "9999 > MAX"

means num. value too low or too high.

Press any key to display permissible min.

or max. value, then enter correct

numerical value.

} see 0

[j [j [j Return to measuring mode level, any changed data accepted into

measuring program

[] Select main menu

C Enter main menu displayed } see f)

01 Measuring mode level

- Plausibility check }

see left for function of keys

- Reset totalizer

01 Main menu level

Function of keys same as under f)

23](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-23-320.jpg)

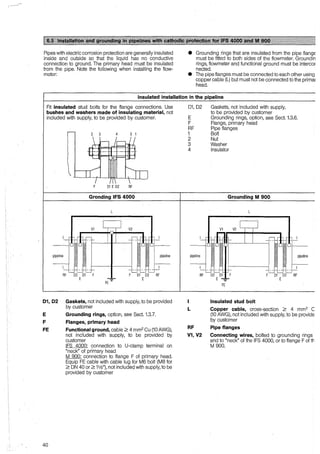

![fä@~!:ri~if.imiii.:!:ii~Ut~ifMfäi{!!l:~H~~!III!IIIIIIlIIII!IIIIIIIIIIII!IIIIIIIIJ!II!lIEtimIIIIIItIIII!tI:ItIIIIl

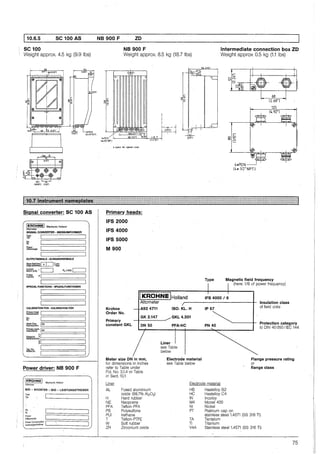

After powering, the signal converter enters the normal measuring mode.

1 Proarammina sfart

- -Key Display Cornments

1st line l2nd linel

ccr::u:u::;rn (ENTER 1, 2, 3, 4, 51 with

} Coding, dependent on programming of

or Fct. 4.02 (YES or NO), refer to Sect. 4.6 + 5.12

rn without

Err. 01„.16 Error(s) in measuring mode, see E-List, Sect. 4.4

appears only, if one or more errors have occurred during measuring Operation

a Err. 02.„16 display next error, if more than one

m terminale error display

Fct. 1.00 !FLOW DATAJ Main menu level, lst main menu displayed, continued as described below

Function of keys in main menu, submenu, functional and data levels, see Sect 4.6

Key Main menu level Submenu level Data level

Functional level Data/Units Numerical values

a Select Select Select next lncrease flashing digit

.main menu submenu or function proposal (cursor) by 1

c Ent.er displayed Enter displayed Return to functional Shift flashing digit (cursor)

mammenu submenu or function level, previous data/units retained 1 place to the right.

Note: If in last position, system

will revert to functional level,

last numerical value retained

rn - - - Revert to main menu Revert to functional level, store new data,

or submenu level units or numerical values temporarily. *

1·

*Flashing display Err. 0000<MIN or Err. 9999>MAX= numerical value too low or too high. Press any key to obtain dis-

play of permissible minimum or maximum value, then enter correct numerical value.

Important

1. Continuously pressing the C or [] key will cause the function of these keys to be continuously repeated (autorepeat

function).

2. If no keystrokes are made for approx. 180 seconds, the signal converter will automatically revert to the measuring mode

without accepting any changed data into the measuring program (time-out function). Exception: if at start of program-

ming errors Err. E04, E05 and/or E14 are established, see Sect. 4.4.

Newly ente:red data will only be accepted into the measuring program ifthe programming mode is terminated

by following the procedure below.

P:rogramming end

Key Display Comments

1st line l2nd linel

1, 2 or 3 x[ai Fct. 1.00„.4.00 Select main menu level

mmm Revert to measuring mode level

Plausibility check, lasts approx. 5 seconds

/

Actua/ measured value No error in plausibility check, any changed data accepted into measuring

program, actual measured value displayed (measuring mode level)

Err. P01...14 Error(s) in plausibility check, see P-List, Sect. 4.5

a Err. P02„.14 Display next error, if more than one

m Fct. 1.00 !FLOW DATAJ Terminate error display and revert to main menu level, Ist main menu displayed,

select faulty function(s) and correct data, see Sect. 4.6

Totalize:r :reset

Key Display l2nd linel Comments

cma IENTER 1, 21 Measuring mode not interrupted

ramm !TOT. RESETJ Totalizer reset

Actua/ measured value Measuring mode level, actual measured value displayed

Clearing e:r:ror messages in measuring mode, see Sect. 4.4

Key Display

1st !ine l2nd linel

IENTER 1,2,3,4,51

or

Err. E01„.E16

Fct. 1.00 !FLOW DATAJ

Actua/ measured value

24

Comments

with 1

without

Goding, dependent on prograrnming of Fct. 4.02

(YES or NO), refer to Sect. 4.6 + 5.12

Error messages (not with Err. E04, E05 and/or E14)

Main menu level

Measuring mode level, actual measured value displayed](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-24-320.jpg)

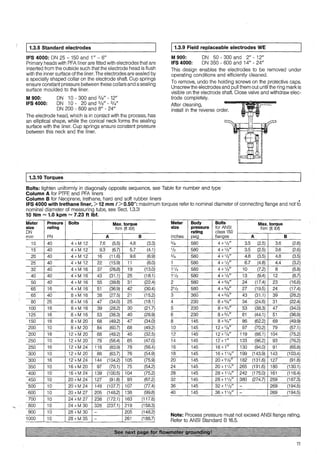

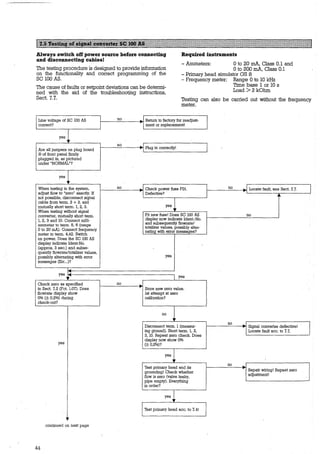

![E-List Description of error Rectify instrument fault Error output in measuring mode via

E:rror messages an.d/or - Display (Fct. 2.04) and/or

clear error message - Status indication output (Fct. 3.3.01)

dependent on programming

Display NO ADC TOT.

lst line* 2nd line MESS. ERROR ERRDR

Err. E01 UNE /NT. Power failure since D - - yes

last programming reset totalizer(s) if necessary

Note: no counting during

power failure

Err. E02 TOTAL/ZER Counts lost or totalizer D - - yes

overflow

Note: totalizer was reset!

Err. E03 DISPLAY Numerical overflow of display Check data Fct. 2.00 - - -

Display lst line: ------------------

Display 3rd line: note T Marker!

Err. E04 EEPROM 1 Data error in EEPROM 1 Check instrument parameters * * * * **

(parameters) 0

Err. E05 CAL. DATA Calibration data lost Recalibrate signal converter, ** * * **

please consult factory

Err. E06 EEPROM 2 Data error in EEPROM 2 (totalizer) D - - yes

Note: totalizer deviation possible reset totalizer(s) if necessary

Err. E07 RAM Check-sum error in RAM 0 - - -

Err. EOB ROM Check-sum error in ROM 0 - - -

Err. E09 AOC ADC value overranged or 0 - yes -

! .

ADC defective

Err. E12 FREQ.OUTP. F Frequency output overranged D - - -

If necess„ check data, Fct. 3.2.00

Err. E13 CUR.OUTP. I Current output overranged D - - -

If necess„ check data, Fct. 3.1.00

Err. E14 EE1 EE2 Current calibration values Terminale programming mode ** ** * *

EPPROM 1+2 are different (press IJ key 4x), values

(occurs only when pc board changed)

corrected automatically

Err. E16 FUSE FS fuse for power failure Fit new F5 fuse, yes*** yes*** yes***

identification defective see Sect. 8.5

* When errors are displayed during the measuring mode, "a numera/" and "Err." will appear in the lst line.

The numeral gives the nurnber of momentarily occurring errors !hat are displayed alternately with the actual measured value.

* * No output in measuring mode! With these errors, the signal converter is automatically in the programming mode.

* * * No output via status indication output (Fct. 3.3.01)

D

0

Invoke and then terminale programming mode.

Keystrokes: 2 XC / 2 X[] / 2 XI] and 4 X IJ or 1 X IJ and 4 XI] (dependent on programming in Fct. 4.02)

Invoke and then terminate programming mode.

Keystrokes: 2 X c I 2 X a I 2 X ra and 4 X IJ or 1 X ra and 4 X ra (dependent on prograrnming in Fct. 4.02)

Consult factory if these errors occur several times in succession.

Err. P.. Text Description

Err. P01 V RANGE Velocity v outside possible range (0.3 to 12 .m/s or 1 to 40 ft/s)

FULL SCALE (Fct. 1.01) <>DIAMETER (Fct. 1.04)

Err. P02 REV. SCALE REV. SCALE (Fct. 1.03) > FULL SCALE (Fct. 1.01)

Err. P03 !RANGE I 0 PCT. (Fct. 3.1.02) > j 100 PCT. (Fct. 3.1.03) or difference < 4 mA

Err. P04 IMAXmA I MAX mA (Fct. 3.1.04) < I 100 PCT. (Fct. 3.1.03)

Err. P05 ICUTOFF I: CUTOFF ON (Fct. 3.1.07);;:::: CUTOFF OFF (Fct. 3.1.08)

Err. P06 FCUTOFF F: CUTOFF ON (Fct. 3.2.08) ;;:::: CUTOFF OFF (Fct. 3.2.09)

Err. P09 F> 10 KHZ Frequency for Q100% > 10 kHz

Err. P10 PULS W!OTH Max. pulse width exceeded (see Fct. 3.2.05)

ALL

ERROR

yes

yes

yes

* *

* *

yes

yes

yes

yes

yes

yes

**

yes

Err. P12 RNG./CUTOFF 2nd range of automatic range change (see Fct. 3.3.02) :S; I CUTOFF ON (see Fct. 3.1.07)

Err. P14 I TRIP PT. I TRIP PT. (Fc:t. 3.3.03) outside range of current output (see Fct. 3.1.04)

25](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-25-320.jpg)

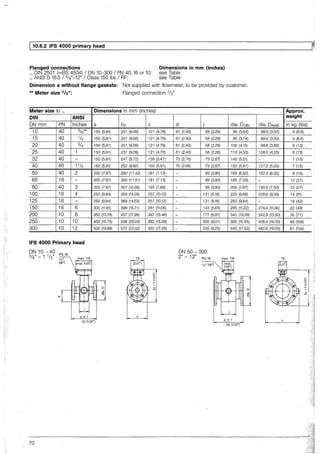

![Fct. No. Text Description and input

3.00 OUTPUTS Main menu 3.00 Outputs

.... -·· ..,„..,. „_...... ..., .;;a""""""l:'"'..........„ .1,,..1,..1.,1,.l.!-'U.L

3.1.00 GUR. OUTP. I Submenu 3.1.00

1.00 FLOW DATA Main menu 1.00 Measurement Current output (I), Seel. 5.7

1.01 FULL SCALE Full-scale range for

flowrate Q1oo%

Unit: select from !ist (Seel. 5.1)

Range: (Seel. 5.3):

0.0034 to 542 900 m3

Ihr or

0.8962 to 143400000 US Glmin

After selecting unit, call numerical

value with C key, lst digjt flashes

1.02 REV. SCALE Different range for reverse

flow? NO or YES

3.1.01 FUNCT/ON I Function, current output (l)

• OFF(= switched off)

e F/R /NO. F(=F/Rindication forF)

• 1 DIR. (= 1 flow direction)

• I < I 0 PCT (=Forward/Reverse

flow, e.g. in 0-20 mA range:

F=l0-20 mA, R=l0-0 mA)

• 2 DIR.(= forward/reverse

flow, F/R measurement)

3.1.02 IO PCT. Current for 0% flow Clo%)

1.03 VALUE Full-scale range for reverse

flow (appears only if YES entered

under Fct. 1.02)

Unit: select from !ist (Seel. 5.1)

Range: 00 to 16 mA

3.1.03 1100 PCT. Current for 100% flow,

Full-scale range (I100%)

Range: 04 to 20 mA

Range: (Sect. 5.3):

0.0034 to 542900 m3

1hr or

(Value at least 4 mA greater

than !hat of Fct. 3.1.02)

0.8962 to 143400000 US Glmin

Value must not be greater

than that of Fct. 1.01

After selectinr;;_ unit ca// numerica/

valua with C key, lst digit flashes

3.1.04 IMAXmA Adjustment of max. output

current Cimaxl

Range: 04 to 22mA

(Value must be greater than/equal

to that of Fct. 3.1.03)

1.04 DIAMETER Meter size 3.1.05 T-CONST. I Time constant, current output

Unit in mm or inch Range: 0.2 to 3600 Sec.

Range: 2 to 4000 mm or

0.0787 to 157.5 inch

After selecting unit, call numerical

3.1.06 L.F.CUTOFFI Low-flow cutoff (SMU) for

current output?

NO or YES (Sect. 5.9)

value· with C key, lst digit flashes 3.1.07 CUTOFFON Cutoff "on" value SMU-I

1.05 GK VALUE Primary constant GK

(see.primary head nameplate)

Range: 0.5 to 14

(appears only if YES entered

under Fct.No. 3.1.06)

Range: 01 to 19 PERCENT

1.06 FLOW DIR. Define direction of forward

(normal) flow

Enter acc. to direction of arrow

{ + or - Jon primary head

1.07 ZERO CALIB. Zero calibration (Sect. 7.2)

Csm out only at "O" flow and when

measurina tube comnl. filled with fluid

3.1.08 CUTOFFOFF Cutoff "off'' value SMU-I

(appears only if YES entered

under Fct. 3.1.06)

Range: 02 to 20 PERCENT

(Value must be greater

than !hat of Fct. 3.1.07)

3.2.00 FRE. OUTP. F Submenu. 3.2.00

1) Inquiry: CALIB. NO or YES Frequency output (F), Sect. 5.8

2) If YES: calibration (duration 45 sec)

with zero display in PERCENT of 0 100%

3) Inquiry: STORE NO or YES

2.00· DISPLAY .·' Main menu 2.00 Display

3.2.01 FUNCT/ON F Function, frequency output (F)

• OFF(= switched off)

e FIR !ND. I (= FIR indication for !)

e 1 DIR.(= 1 flow direction)

2.01 OISP. FLOW Unit for flowrate display

• m

3

/Sec • m

3

Imin • m

3

/h

• 2 DIR.(= forward/reverse

flow, F/R measurement)

• Liter/Sec • Liter/min • Liter/h 3.2.02 PULSOUTP. Unit, frequency output

e US G/Sec e US Glmine US Glh e PULSRATE (= input in pulses

e h Literlhr or US MG/DA Y per unit time)

(=hectoliters per hour, for US version e PULSE/UN/T (= input in pulses

US million gallons per day) factory per unit volume)

set, can be changed as required

via Fct. 4.04, 4.05+4.06 (Sect. 5.14)

e PERCENT

e NO DISPLAY

2.02 UNIT TOTAL. Unit for totalizer display

• m

3

• Liter • US G

3.2.03 PULSRATE Pulse rate for 100% flowrate

(appears only if PULSRATE

entered under Fct. 3.2.02)

Range:

2.778*10-3

to 10000 pulses/Sec

0.1667 to 600000 pulseslmin

• h Liter or US MG (hectoliters 10 to 36 000 000 pulseslhr

or US million gallons) see After selecting unit, call numerical

Fct.No. 2.01 {h LiterIhr or US G/DAY)

2.03 O/SP. TOTAL. Function of totalizer display

• + TOTAL. (= forward totalizer)

• - TOTAL. (= reverse totalizer)

• +/- TOTAL. (= forward and

reverse flow totalizers, altemating)

e SUM TOTAL. (= sum of + and

- totalizers)

e ALL TOTAL. (= sum, + and

- totalizers, altemating)

e NO O/SPLAY (= totalizer

switched on but no display)

e TOTAL. OFF(= totalizer

switched off)

value with C key, lst digjt flashes

3.2.04 PULSE/UN/T Pulse value

(appears only if PULSEIUNIT

entered under Fct. 3.2.02),

Unit in pulses per m3, Liter, US G

or unit of Fct. 4.04, 4.05 + 4.06

(Sect. 5.14) - Range:

0.0001 to 0.9999*109

pulses

[no input check but:

0100%* pulse value ::::;

36 000 000 pulses ~ 10 kHz]

After selecting unit, call numerical

value with C key, lst digjt flashes

2.04 ERRORMSG Which error messages to 3.2.05 PULS WIOTH Pulse width for frequencies ::::;10Hz

be displayed? (Seel. 4.4)

• 30mSec.

• 50mSec.

e NO MESSAGE • 100mSec. • 200mSec.

(= no error messages) • 500mSec.

e AOC ERROR (= only ADC

conversion errors)

e TOT ERROR

(= only errors of intemal totalizer)

e ALL ERROR (=all errors)

2.05 O/SP. TEST Carry out display test

Start with C key

3.2.06 T-CONST. F Time const. for frequency output

T< F> = 0.2 Sec.

T< F> = T< I >(=time constant

for F same as for I, Fct. 3.1.05)

3.2.07 L.F.CUTOFF F Low-flow cutoff (SMU) for

frequency output

NO or YES (Sect. 5.9)

26](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-26-320.jpg)

![Fct. No. Text Description and input Fct. No. Text Description and input

3.2.08 CUTOFFON Cutoff "on" value SMU-F 4.00 SPEC. FCT. Main menu 4.00

(appears only if YES entered Special functions

under Fct. 3.2.07)

Range: 01 to 19 PERCENT

4.01 LANGUAGE Language of display texts, Sect. 5.11

e GB/USA (= English)

3.2.09 CUTOFFOFF Cutoff "off'' value SMU-F • 0 (= German)

(appears only if YES entered e F (= French)

under Fct. 3.2.07) e SF (= Finnish)

Range: 02 to 20 PERCENT • others pendinq

(Value must be greater

than that of Fct. 3.2.08)

4.02 ENTRYCOOE Coding for entry into

programming mode? Sect. 5.12

3.3.00 /NO. OUTP. S Submenu 3.3.00 Status indication

output (S), Sect. 5.16

• NO = entry with 1:§1 key

• YES = entry with keys

3.3.01 FUNCTION S Funct. of status indication output

• OFF(= switched off,

0 V at term. 4/43)

• ON(= switched on,

24 V at term. 4/43, e.g. as

operational status indicator

e FIR /NO. I (= FIR indication

c c [][][§1 [§1

4.03 OUTP. HOLD Hold values of outputs

during programming?

NO or YES (Sect. 5.13)

4.04 UNITTEXT Text for field-programmable

unit, Sect. 5.14

for I), Sect. 5.10 A„.Z I a„.z / 0„.9 I _ (= space)

e F/R /NO. F (= F/R indication 4.05 FACT. QUANT. Conversion factor for

for F), Sect. 5.10

e AUTO. RANGE (= automatic

range change), Sect. 5.16

• I TRIP. PT. (= trip point I as %

quantity FM, Sect. 5.14

Factor FM= quantity l§er 1 m3

Range: 0.00001*10- to

9.99999*10+9

of 0100%• Fct. 3.3.03)

e F TRIP. PT. (= trip point F as %

of 0 100%, Fct. 3.3.04)

e L.F.CUTOFF I (= low-flow cutoff I),

Fct. 3.1.06

e L.F.CUTOFF F (= low-flow cutoff F)

Fct. 3.2.07

4.06 FACT. TIME Conversion factor for time FT

Sect. 5.14

Factor FT in seconds

Range: 0.00001*10-9

to

9.99999* 10+9

4.07 FIELO FREQ. Magnetic field frequency,

e AOC ERROR}

e TOT. ERROR s. E-List Sect. 4.4

e ALL ERROR

Sect. 5.15+8.2

• 116 • 1116 • 1132

4.08 NO/SE Noise rejection, Sect. 6.2 .,

3.3.02 AUTO. RANGE Automatie range change for e NO NO/SE

current output, see Sect. 5.17 e NO/SE

(appears only if AUTO. RANGE

enternd under Fct. 3.3.01)

4.09 REF. SEL. Selecting the reference voltage

Sect. 6.2

Range: 05 to 80 PERCENT of 0 100%, e AUTO. REF.

(Value must be greater than

SMU-1 cutoff "on" value, Fct. 3.1.07)

(= automatic rnfernnce)

e HIGH-FLOW

3.3.03 I TRIP PT. Trip point for current output, (= high flow range)

Sect. 5.18 (appears only if e MED1-FLOW

I TRIP PT. enternd underFct. 3.3.01) (= lst medium flow range)

Range: 001 to 110 PERCENTof 0 100%

(Value must be greater than

e ME02-FLOW

(= 2nd medium flow range)

SMU-1 cutoff "off" value, Fct. 3.1.08) e MED3-FLOW

3.3.04 F TRIP PT. Trip point for frequency output,

Sect. 5.18 (appears only if

F TRIP PT. entered under Fct 3.3.01)

(= 3rd medium flow range)

e LOWFLOW

(= low flow ranqe)

Range: 001 to 115 PERCENTof 0 100% 4.10 FIELD GUR. Input of field current

(Value must be grnater than

SMU-F cutoff "off" value, Fct. 3.2.09)

Range: 225.00 to 275.00 mA

(see sticker at term 7 + 8 on

"basic" pc board/with power driver

NB 900 F always ± 250 mA)

Must not be changed, Sect. 7.2 + 8.1!

27](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-27-320.jpg)

![e To avoid erroneous measurements at lowflowrates, the

S:rvfTJ SV'"Vitches the CUi--rent fu!d frequency outputs (I+F)

off. I goes to Io% (Fct. 3.1.02) and F to 0 Hz.

• If "NO"is entered underfunctions 3.1.06 +3.2.07, fixed

cutoff "on" and cutoff "off" values of 0.1 and 0.25%,

resp., of 0100% (full-scale range, see Fct. 1.01) act on the

outputs I + F.

• If "YES"is entered under functions 3.1.06 + 3.2.07, the

cutoff "on" and cutoff "off" values forI +F are separately

adjustable in the ranges specified below.

• The low-flow cutoff (SMU) can be indicated either for I

orfor F via the status indication output S(see Sect. 5.16).

Fct. 3.1.06 Low-flow cutoff (SMU) for I desired?

Enter NO or YES.

Fct. 3.1.07 Cutoff "on" value for SMU-I

(appears only if "YES" entered in Fct. 3.1.06)

Range: 01to19 PERCENTof 0 100% -

The low-flow cutoffdrives the current outputto lo% when the

flow decreases to the cutoff "on" value (see Fct. 3.1.02).

Fct. 3.1.08 Cutoff "ofr' value for SMU-I

(appears only if "YES" entered in Fct. 3.1.06)

Range: 02 to 20 PERCENTof 0 100%

This value must be greater than that of Fct. 3.1.07, other-

wise a "plausibility" error (Err. POS) will occur, see Sect. 4.5.

When the flow returns to the cutoff "off" value, the current

output returns to normal.

Fct. 3.2.07 Low-flow cutoff (SMU) for F desired?

Enter NO or YES:

Fct. 3.2.08 Cutoff "on" value for SMU-F

(appears only if "YES" entered in Fct. 3.2.07)

Range: 01to19 PERCENTof 0 100%

The low-flow cutoff drives the frequency output to 0 Hz

when the flow decreases to the cutoff "on" value.

Fct. 3.2.09 Cutoff "off" value for SMU-F

(appears only if "YES" entered in Fct. 3.2.07)

Range:: 02 to 20 PERCENTvon 0 100%

This value must be greater than that of Fct. 3.2.08, other-

wise a "plausibility" error (Err. P06) will occur, see Sect. 4.5.

When the flow returns to the cutoff "off" value, the fre-

quency output returns to normal.

!iil#J.mt.ml„ii~ii~ttiii~i~[m.@li#lfüfüJI1J11111t11tH~I

Electrical connection, characteristic and programming of

outputs, refer to Sect. 2.6, 5.7 + 5.8.

Fct. 1.06 Define direction of forward (normal) flow

(+ or -)

In the case of F/R operation, program the direction of the

forward flow with "+"or"-·:in accordance with the arrows

marked "+" and "-" on the primary head. Note that if the

flowmeter does not have a "+" and "-" on the primary head

the "+" direction is the direction the arrow is pointing.

Fct. 1.01 Full-scale setting for flowrate 0 1oo%

Program the full-scale range. Unit and range, see Sect. 5.1

+ 5.3.

Fct. 1.02 Separate range desired for reverse flow?

Enter "YES" only if the range required for reverse flow is

differentfrom the range for the normal (forward) flow. Ifnot,

enter "NO".

34

Fct. 1.03 Full-scale range for reverse flow

(appears only if "YES" entered in Fct. 1.02). This is used fo:

programming the full-scale range for reverse flow. Uni

and range, see Sect. 5.1 + 5.3. This value must not bE

greater than that of Fct. 1.01, otherwise "plausibility" erro:

(Err. P02) will occur, see Sect. 4.5.

A choice of languages for the display texts is offered ir

Fct. 4.01:

• GB/US English

• D Gerrnan

• F French

e SF Finnish

other languages pending.

11ii1111•1i11~~llillli~;lllllilllll1Bllljlll

• Enter NO or YES.

• If "NO" entered, there are 2 ways of entering the pro-

gramming möde:

1. by pressing the mkey only or

2. by pressing the C C [] [] 1]11]1 keys.

• If "YES" entered, the only way of entering the

programming mode is to press keys as follows:

ccaamm

tm.11j~!ii!Hiij~ifji!mimi~liHiiIIWfiim~iiIIIM

e Enter in Fct. 4.03 whether or not the outputs shall hold

the last values (before entry into the programming

mode).

• If "YES" entered: output values prior to entry into the

programming mode are retained duringprogramming.

After leaving the programming mode, the outputs go to

the values corresponding to the actual operating condi-

tions.

e If "NO" entered: the outputs go to the programmed

minimum values:

I to the value of Io% (see Fct. 3.1.02)

F to 0 V, consequently no pulses

S to 0 V.](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-34-320.jpg)

![An arbitrary volumetrie flow unit or, if density of the fluid

produet is consistent and knovvn, a unit of mass (weight)

ean be programmed in funetions 4.04 to 4.06. The unit

"h Literlhr" (heeto-liters per hour) is faetory-set unless

another special unit is speeified. US-version: "US

MG/DA Y" (US million gallons per day).

Fct. 4.04 Text for field-programmable unit

• Volumetrie (or mass) unit per unit time

• Text for volume (mass): 6 charaeters (places)

• Text for time: 3 characters (plaees)

9 The fraction bar "/" in the 7th plaee has a fixed position.

• Alpha charaeters A-Z and a-z, numbers 0-9 or blank

charaeter (J are seleetable for every plaee.

• Pressing the [] key will sequenee the alpha eharaeters

and numbers in the order given above.

• The C key shifts the eursor 1 plaee to the right.

• Text examples are given in the following Tables in

braekets (....../...).

Fct. 4.05 Conversion factor Quantity FM

Enter the faetor FM= quantity per 1 m3

.

Volumetrie unit Factor FM

Cubie meters (m 3) 1.0

Liters (Liter) 1000

Heeto-liters lhLiter) 10

Deei-liters (d Liter) 10000

Centi-liters (c Liter) 100000

Milli-liters (m Liter) 1000000

US gallons (US G) 264.172

US million

0.000264172gallons (US MG)

Imperial gallons

219.969(GB G)

Imperial mega-

0.000219969gallons (GB MG)

Cubie feet (Feet 3) 35,3146

Cubie inehes (inch 3) 61024.0

US barrels liquid 8.38364

US fluid ounees 33813.5

Fct. 4.06 Conversion factor Time FT

Enter the faetor Fr in seeonds.

Time unit Factor FT

[seconds]

Seeond (Sec) 1

Minute (min) 60

Hour (hr) 3600

Day (DAY) 86400

Year (YR)

31536000(.2. 365 days)

Fct. 1.05 GK value

Inpuit

1.00000± 0

1.00000 + 3

1.00000 + 1

1.00000 + 4

1.00000 + 5

1.00000 + 6

2.64172 + 2

2.64172 :-- 4

2.19969 + 2

2.19969 - 4

3.53146 + 1

6.10240+ 4

8.38364± 0

3.38135 + 4

Input

1.00000± 0

6.00000 + 1

3.60000 + 3

8.64000 + 4

3.15360 + 7

'J'he primfily eonstant GK is faetory-set. Range: 0.5 to 14,

dependent on primary head, see instrument nameplate.

Examples of volume per unit time

Desired Hecto-liters Deci-liters

units: per year per hour

Volumetrie

unit h Liter d Liter

in Fet. 4.04

Faetor FM 10 10000(see Table)

Input in

1.00000 + 1 1.00000 +4Fet. 4.05

Time unit

YR hr

in Fet. 4.04

Faetor Fr 31536000 3600

(see Table) (seconds) (seeonds)

Input in

3.15360 + 7 3.60000 +3Fet. 4.06

Examples of mass per unit time

Produet density Q = 1.2 g/em3

= 1.2 kg/Liter= eonstant

Mass of 1 m3 produet = 1200 kg = 2646 pounds

Desired Kilograms Pounds

unit: per minute per hour

Mass unit

kg lbs

in Fet. 4.04

Factor FM

1200 2646(see Table)

Input in

1.20000 + 3 2.646 + 3Fet. 4.05

Time unit

min hrin Fet. 4.04

Factor Fr 60 3600(see Table)

Input in

6.00000 + 1 3.60000 +3Fet. 4.06

Fct. 4.07 Magnetic field frequency

The magnetie field frequeney is factory-set to 116, 1116

or 1132 of the power frequeney, see signal eonverter

nameplate.

Data of Fct. 1.05 + 4.07 must not be changed! Exeeption: replaeement of prirn.ary head, see Seet. 8.2

35](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-35-320.jpg)

![Part C Special applications, functional checks and senice

6. Special applications

!fäi~j,tJfä~t#miw.Ji.tiii.iil~~~iJlitf@tltltI{Ifüillitft!

Altoflux electromagnetic flowmeters are certified to Euro-

pean standards and to Factory Mutual standards

(FM) as electrical appliances suitable for use in hazar-

dous areas.

Onlythe primaryheads are permitted tobe installed

in the hazardous area. The signal converter must always

be installed outside the hazardous area.

Allocation oftemperature class to temperature ofthe fluid,

meter size and material of the measuring tube liner is spe-

cified in the test certificate.

Since the intrinsically safe signal circuit is grounded under

field conditions via the fluid, equipotential bonding is

required in the entire hazardous area andin the cable run

ofthe mtrinsically safe signal circuit (inside and outside the

hazardous area).

Test certificate, certificate ofconformity and wiring

instructions are attached to the Installation and

Operating Instructions (applies only to hazardous-

duty equipment).

lli~~ll!ll.lllllrt1~11111illl~lilllillllilillill·:llllil:::

The signal converter is equipped with an intemal automa-

tic reference unit which ensures optimum adjustment to

the input signal from the primary head during changing

flowrates.

In the case of rapidly changing flowrates, e.g. batching

processes and where operation with reciprocating pumps

is involved, it may be necessary to influence or cut out this

automatic unit via Fct. 4.08 and 4.09.

With Fct. 4.08, the response time of the automatic unit is

decreased by up to 30%.

The automatic unit is switched off via Fct. 4.09. However,

this reduces the measuring accuracy of the signal con-

verter.

Since there are no hard and fast rules for applying Fct. 4.08

and 4.09, it is advisable to determine the optimum setting

as follows.

Always switch off the power source before connec-

ting and disconnecting cables!

• Connect an LED with series resistor (0.68 to 2 kohms) or

an oscilloscope to terminals 4 + 43 (digital voltmeters

are unsuitable).

• Program "ADC ERROR"in Fct. 3.3.01 (status indication

output).

• Start the flow.

• The optimum setting for the signal converter is found

when the LED does not turn off (remains lighted),

• If the LED tums off, even momentarily, reprogram the

signal converter in the following order until the LED

remains on (lighted).

Order Fct. 4.08 Fct. 4.09

lst NO/SE AUTO. REF.

2nd NO NO/SE HIGH FLOW

3rd NO NO/SE MED1-FLOW

4th NO NO/SE MED2-FLOW

5th NO NO/SE MED3-FLOW

6th NO NO/SE LOWFLOW

• Subsequently, reprogram Fct. 3.3.01 (status indication

output) according to its original application.

• If the above procedure does not lead to the desired

effect, please consult factory.

l'::~1~::1lllRlil~ll~~i:lllll!l~llit~:·111111i1iill1:llllililllllll

Output values can be stabilized to values as for "zero" flow

to prevent random output signals when the measuring tube

is empty orwhen the electrodes are notwetted in the event

the measuring tube is partially full.

This means:

Totalizer Display - does not accumulate random

counts

Current output - value of Io% (see Fct. 3.1.02)

Frequency output - 0 V(= no pulses)

Preconditions

• Electrical conductivity offluid ~ 200 µSlcm (µmholcm)

[~ 500 µSlcm (µmholcm) in conjunction with primary

head IFS 5000 (-Ex), DN::; 15 or:::;; 1/ 2"]

• Max. signal cable length 50 m (165 ft), for cable type DS

or BTS.

Changes on basic pc board

(see components drawing, Sect. 9.1)

• Insert two resistors Rx = 10 Mohms

• Insert soldering jumper Lx.

Additional change to programming

Program low-flow cutoff (SMU) for current output I and fre~

quency output F as follows (minirnum values):

Fct. 1 F Comments

3.1.06

YES YES Activate SMU

3.2.07

3.1.07

1 PERCENT 1 PERCENT Cut off "on" value

3.2.08

3.1.08

2 PERCENT 2 PERCENT Cut off "off" value

3.2.09

Note

The low-flow cutoff function does not affect the flowrate

display, Fct. 2.01: DISP. FLOW Therefore, depending

upon the resolution of this display, there may be a slight

positive or negative flowrate displayed during the period

the pipe is empty or the measuringtube electrodes are not

wetted.

lii:ll:lll.r.~l.lllf.lllllmllllllilil:ji!j:llililllliillllil:iill:l

• The signal converter can optionally be equipped with

magnetic sensors, see Sect. 4.1, Item 5.

e This allows programming of the signal converter by

means of a hand-held bar magnet. Function of sensors

without removing the front cover is the same as the cor-

responding keys. Sensor response is acknowledged

by symbols in the lst line of the display.

• Hold the bar magnet by the black rubber cap. Apply

blue end of the magnet (north pole) to the glass pane

above the magnetic sensors.

39

'1](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-39-320.jpg)

![Condensed lnstructions - SC 100 AS 0119s IKROHNE j

3K24E/A6 019521 Printed in Gennany Subject to change without notice. ° Copyright KROHNE-Messtechnik GmbH & Co.

[:j~iM~llfü8ii#ifüi!I~ii1tfJ1111fI1lfitff1f11Ilfilfill1t1HlHII1Il!Itttt!füilfl@1Hf1@[~f[llHf1Ittmm

After powering, the signal converter enters the normal measuring mode.

Key Display 1st line l2nd linel Comments

CCDD1111l (ENTER 1, 2, 3, 4, 5]

with 1 Coding, dependent on programrning of

or

a

D

Key

a

c

Err. 01...16

Err. 02... 16

Fct. 4.02 (YES or NCI';, refer to Seel. 4.6 +5.12

without

Error(s) in measuring mode, see E-List, Sect. 4.4

appears only, if one or more errors have occurred during measuring operation

display next error, if more than one

terminale error display

Fct. 1.00 lFLOW OATAJ Main menu level, lst main menu displayed, continued as described below

Main menu level

Select

mainmenu

Enter dIBplayed

mainmenu

Submenu level

Functional level

Select

submenu or function

Enter displayed

submenu or function

Revert to main menu

or submenu level

Data level

Data/Units

Select next

proposal

Return to functional

level, previous data/units retained

Numerical values

Increase flashing digit

(cursor) by 1

Shift flashing digit (cursor)

1 place to the right.

Note: If in last position, system

will revert to functional level,

last numerical value retained

Revert to functional level, store new data,

units or numerical values temporarily. *

*Flashing display Err. 0000< M/Nor Err. 9999> MAX=numerical yalue too low ortoohigh. Press anykeyto obtain dis-

play of perrnissible minimum or maximum value, then enter correct numerical value.

Important ·

1. Continuously pressing the C or D key will cause the function of these keys to be continuously repeated (autorepeat

function).

2. lfno keystrokes are made for approx. 180 seconds, the signal converter will automatically revert to the measuring mode

without accepting any changed data into the measuring program (time-out function). Exception: if at start of program-

ming errors Err. E04, E05 and/or E14 are established, see Sect. 4.4.

Newly entered data will only be accepted into the measuring program ifthe programming mode is terminated

by following the procedure below.

Key

1, 2 or 3 xi]

llllll

Key

CllD

ll ll ll

Key

ccaamm

o:r

Display 1st line l2nd linel

Fct. 1.00...4.00

Actua/ measured value

Err. P01...14

Err. P02...14

Fct. 1.00 lFLOW DATAJ

Display l2nd linel

lENTER 1, 21

lTOi. RESETJ

Actua/ measured value

Display 1st line l2nd Jinel

lENTER 1,2,3,4,51

Err. E01...E16

Fct. 1.00 lFLOW DATAJ

Actua/ measured value

Comments

Select main menu level

Revert to measuring mode level

Plausibility check, lasts approx. 5 seconds

lfo error in plausibility check, any changed data accepted into measuring

prograrn, actual measured value displayed (measuring mode level)

Error(s) in plausibility check, see P-List, Sect. 4.5

Display next error, if more than one

Terminate error display and revert to main menu level, lst main menu displayed,

select faulty function(s) and correct data, see Sect. 4.6

Comments

Measuring mode not interrupted

Totalizer reset

Measuring mode level, actual measured value displayed

Comments

with lwithout

Coding, dependent on programrning of Fct. 4.02

(YES or NCJ), refer to Sect. 4.6 + 5J2

Error messages (not with Err. E04, E05 and/or E14)

Main menu level

Measuring mode level, actual measured value displayed

A](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-43-320.jpg)

![Text

1.01 FULL SCALE

1.02 REV. SCALE

1.03 VALUE

1.04 DIAMETER

1.05 GKVALUE

1.06 FLOW DIR.

1.07 ZERO CALIB.

2.01 DISP. FLOW

2.02 UNITTOTAL.

2.03 DISP. TOTAL.

2.04 ERRORMSG

2.05 DISP. TEST

B

Desc::ription and input

:e'n .i>~!!~B:;.

Full-sc::ale range for

ßowrate 0100%

Unit: select from list (Sect. 5.1)

Range: (Sect. 5.3):

0.0034 ta 542900 m3

Ihr or

0.8962ta143400000 US G/min

After selecting unit. call numerical

value with C key. Ist diqit flashes

Different range for reverse

ßow? NO or YES

Full-sc::ale range for reverse

ßow (appears only if YES entered

under Fct. 1.02)

Unit: select from list (Sect. 5.1)

Range: (Sect. 5.3):

0.0034 ta 542900 m3

Ihr or

0.8962 ta 143400000 US G/min

Va/ue must not be greater

than that af Fct. 1.01

After se/ectjng unit ca// numerica/

value with C key. Ist diqit flashes

Meter size

Unit in mm or inch

Range: 2 ta 4000 mm or

0.0787 ta 157.5 inch

After selecting unit. call numerical

value with C key, Ist diqit flashes

Primary c::onstant GK

(see primary head nameplate)

Range: 0.5 ta 14

Deime direc::tion of forward

(normal) ßow

Enter acc. to direction of arrow

( + or - J on primary head

Zero c::alibration (Sect. 7.2)

Carry out only at "O" flow and when

measurin tube com 1. filled with fluid

1) Inquiry: CALIB. NO or YES

2) If YES: calibration (duration 45 sec)

with zero display in PERCENT of 0100%

3) Inquiry: STORE NO or YES

'"'II,

Unit for ßowrate display

• m3

/Sec • m

3

Imin • m

3

lh

• Liter/Sec • Liter/min • Literlh

e US G/Sec e US G/mine US Glh

e h LiterIhr or US MG/DA Y

(=hectoliters per hour, for US version

US million gallons per. day) factory

set, can be changed as required

via Fct. 4.04, 4.05+4.06 (Sect. 5.14)

e PERCENT

e NO DISPLAY

Unit for totalizer display

• m

3

• Liter • US G

• h Liter or US MG (hectoliters

or US million gallons) see

Fct.No. 2.01 (h LiterIhr or US G!DAY)

Func::tion of totalizer display

• + TOTAL. (= forward totalizer)

• - TOTAL. (= reverse totalizer)

e +/- TOTAL. (= forward and

reverse flow totalizers, altemating)

e SUM TOTAL. (= sum of + and

- totalizers)

e ALL TOTAL. (= sum, + and

- totalizers, altemating).

e NO D/SPLAY (= totalizer

switched on but no display)

e TOTAL. OFF(= totalizer

switched off)

Whic::h error messages to

be displayed?· (Sect. 4.4)

e NO MESSAGE

(= no error messages)

e ADC ERROR (= only ADC

conversion errors)

e TOT. ERROR

(= only errors of intemal totalizer)

e ALL ERROR (=all errors)

Carry out display test

Start with CJ key

3.1.01 FUNCTIONI

3.1.02 I 0 PCT.

3.1.03 1100 PCT.

3.1.04 IMAXmA

3.1.05 T-CONST. I

3.1.06 L.F.CUTOFFI

3.1.07 CUTOFFON

3.1.08 CUTOFFOFF

3.2.01 FUNCT/ON F

3.2.02 PULSOUTP.

3.2.03 PULSRATE

3.2.04 PULSE/UN/T

3.2.05 PULS WIDTH

3.2.06 T-CONST. F

3.2.07 L.F.CUTOFF F

Func::tion, c::urrent output (1)

e OFF (= switched off)

e FIR /NO. F(=F/RindicationforF)

• 1 DIR. (= 1 flow direction)

• I < I 0 PCT. (=Forward/Reverse

flow, e.g. in 0-20mA range:

F=l0-20 mA, R=l0-0 mA)

• 2 DIR. (= forward/reverse

flow, F/R measurement)

Current for 0% ßow CJoq.)

Range: 00 ta 16 mA

Current for 100% ßow,

Full-scale range CI100%)

Range: 04 ta 20 mA

(Value at least 4 mA greater

than that of Fct. 3.1.02)

Adjustment of max. output

c::urrent Cimax)

Range: 04 ta 22mA

(Value must be greater than/equal

to that of Fct. 3.1.03)

Time c::onstant, c::urrent output

Range: 0.2 ta 3600 Sec.

Low-ßow c::utoff (SMU) for

c::urrent output?

NO or YES (Sect. 5.9)

Cutoff "on" value SMU-I

(appears only if YES entered

under Fct.No. 3.1.06)

Range: 01 ta 19 PERCENT

Cutoff "off" value SMU-I

(appears only if YES entered

under Fct. 3.1.06)

Range: 02 ta 20 PERCENT

(Value must be greater

than that of Fct. 3.1.07)

Func::tion, frequenc::y output (F)

• OFF(= switched off) _

e FIR !NO. I (= FIR indication for I)

• 1 DIR. (= 1 flow direction)

• 2 DIR. (= forward/reverse

flow, F/R measurement)

Unit, frequenc::y output

e PULSRATE (= input in pulses

per unit time)

e PULSE/UNIT(= input in pulses

per unit volume)

Pulse rate for 100% ßowrate

(appears only if PULSRATE

entered under Fct. 3.2.02)

Range:

2.778*10-3

ta 10000 pulses/Sec

0.1667 ta 600 000 pu/ses/min

10 ta 36 000 000 pu/ses/hr

After selecting unit, call numerical

value with C key, lst diqit flashes

Pulse value

(appears only if PULSE/UN/T

entered under Fct. 3.2.02),

Unit in pulses per m3

, Liter, US G

or unit of Fct. 4.04, 4.05 + 4.06

(Sect. 5.14) - Range:

0.0001 ta 0.9999*1a9 pu/ses

[no input check but:

0100%* pulse value ::;

36 000 000 pulses ~ 10 kHz]

After selecting unit, call numerical

value with C key, Ist digit flashes

Pulse width for frequenc::ies ::;toHz

• 30mSec. • 50mSec.

• 1OOmSec. • 200mSec.

• 500mSec.

Time c::onst. for frequency output

T< F> = 0.2 Sec.

T< F> = T< I >(=time constant

for F same as for !, Fct. 3.1.05)

Low~flow c::utoff (SMU) for

frequenc::y output

NO or YES (Sect. 5.9)](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-44-320.jpg)

![Fct. No. Text

3.2.08 CUTOFFON

3.2.09 CUTOFF OFF

3.3.01 FUNCTION S

3.3.02 AUTO. RANGE

3.3.03 I TRIP PT.

3.3.04 F TRIP PT.

Description and input

Cutoff "on" value SMU-F

(appears only if YES entered

under Fct. 3.2.07)

Range: 01to19 PERCENT

Cutoff "off'' value SMU-F

(appears only if YES entered

under Fct. 3.2.07)

Range: 02 to 20 PERCENT

(Value must be greater

than that of Fct. 3.2.08)

Funct. of status indication output

• OFF(= switched off,

0 V at term. 4/43)

• ON(= switched on,

24 V at term. 4/43, e.g. as

operational status indicator

e FIR /NO. I (= FIR indication

for I), Sect. 5.10

e FIR /NO. F (= FIR indication

for F), Sect. 5.10

e AUTO. RANGE(= automatic

range change), Sect. 5.16

e I TRIP. PT. (= trip point I as %

of 0100%, Fct. 3.3.03)

e F TRIP. PT. (= trip point F as %

of 0100%, Fct. 3.3.04)

e L.F.CUTOFF I (= low-fl.ow cutoffI),

Fct. 3.1.06

e L.F.CUTOFF F (= low-flow cutoff F)

Fct. 3.2.07

e AOC ERROR}

e TOT. ERROR s. E-List Sect. 4.4

e ALL ERROR

Automatie range change for

current output, see Sect. 5.17

(appears only if AUTO. RANGE

entered under Fct. 3.3.01)

Range: 05 to 80 PERCENT of 0100%•

(Value must be greater than

SMU-I cutoff "on" value, Fct. 3.1.07)

Trip point for current output,

Sect. 5.18 (appears only if

I TRIP PT. entered under Fct. 3.3.01)

Range: 001to110 PERCENTof 0100%

(Value must be greater than

SMU-I cutoff "off" value, Fct. 3.1.08)

Trip point for frequency output,

Sect. 5.18 (appears only if

F TRIP PT. entered under Fct. 3.3.01)

Range: 001to115 PERCENTof010o%

(Value must be greater than

SMU-F cutoff "off" value, Fct. 3.2.09)

4.02 ENTRYCODE

4.03 OUTP. HOLD

4.04 UNITTEXT

4.05 FACT. QUANT.

4.06 FACT. TIME

4.07 FJELD FREQ.

4.08 NO/SE

4.09 REF. SEL.

4.10 FJELD GUR.

Coding for entry into

programming mode? Sect. 5.12

• NO = entry with fil key

• YES = entry with keys

CJ CJ [] IJ fil fil

Hold values of outputs

during programming?

NO or YES (Sect. 5.13)

Text for field-programmable

unit, Sect. 5.14

A„.Z I a„.z I 0„.9 / _ (= s ace)

Conversion factor for

quantity FM, Sect. 5.14

Factor FM= quantity ~er 1 m3

Range: 0.00001*1U to

9.99999*10+9

Conversion factor for time FT

Sect. 5.14

Factor FT in seconds

Range: D.00001*1U9

tci

9.99999* 1o+9

Magnetic field frequency,

Sect. 5.15+8.2

• 116 • 1116 • 1132

Noise rejection, Sect. 6.2

e NO NO/SE e NO/SE

Selecting the reference voltage

Sect. 6.2

e AUTO. REF.

(= automatic reference)

e HIGH-FLOW

(=high flow range)

e ME01-FLOW

(= lst medium flow range)

e ME02-FLDW

(= 2nd medium flow range)

e ME03-FLOW

(= 3rd medium flow range)

e LOWFLOW

(= low flow ran e)

Input of field current

Range: 225.00 to 275.00 mA

(see sticker at term 7 + 8 on

"basic" pc board/with power driver

NB 900 F always ± 250 mA)

Must not be changed, Sect. 7.2 + 8.1!

Please note: signal converter SC 100 AS/HPC/S, new structure of main menu 4.0 Special functions

4.02 ENTRYCOOE

4.03 OUTP. HOLD

4.04 UNITTEXT

4.05 FACT. QUANT.

4.06 FACT. TIME

Language of display texts; Sect. 5.11

e GB/USA (= English)

• 0 (= German) • F (= French)

• SF (= Finnish) • others endin

Coding for entry into

programming mode? Sect. 5.12

e NO = entry with l]I key

• YES = entry with keys

aaccmm

Hold values of outputs

during programming?

NO or YES (Sect. 5.13)

Text for field-programmable

unit, Sect. 5.14

A„.Z I a...z / 0„.9 I _ (= s ace)

Conversion factor for

quantity FM, Sect. 5.14

Factor FM= quantity ~er 1 m3

Range: 0.00001*1U to

9.99999*1o+9

Conversion factor for time FT

Sect. 5.14

Factor FT in seconds

Range: 0.00001*1U9

to

9.99999*10+9

Fct. No.

4.07

4.08

4.09

4.10

4..11

4.12

Text Description and input

FJELD FREQ. Magnetic field frequency,

Sect. 5.15+8.2

• 116 • 1116 • 1132

SCALE SEL. Select preamplification, Sect. 13

•AUTO (automatic)

e HIGH FLOW (high flow range)

• MED. FLOW (medium flow range)

• LOW FLOW (low flow range)

FJELD GUR. Input of field current

Range: 225.00 to 275.00 mA

(see sticker at term '] + 8 on

"basic" pc board/with power driver

NB 900 F always ± 250 mA)

Notto be changed, see Sect. 7.2 + 8.1

NO/SE Noise rejection, see Sect. 13

eND e YES

LIMITCNT Counter for off-lirnit condition

(appears only if YES entered under

(Fct. 4.10 NO/SE), see Sect. 13

Range: 001 to 250

LIMIT VAL Limit value for noise amplitude

(appears only if YES entered under

Fct. 4.10 NO/SE), see Sect. 13

Ranqe: 01 to 90 PERCENT

c](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-45-320.jpg)

![1 Err. P„ 1 Text 1 Description

Err. P01 V RANGE Velocity v outside possible range (0.3 to 12 m/s or 1 to 40 ft/s)

FULL SCALE (Fct. 1.01) < > DIAMETER (Fct. 1.04)

Err. P02 REV. SCALE REV. SCALE (Fct. 1.03) > FULL SCALE (Fct. 1.01)

Err. P03 IRANGE I 0 PCT. (Fct. 3.1.02) > I 100 PCT. (Fct. 3.1.03) or difference < 4 mA

Err. P04 IMAXmA I MAX mA (Fct. 3.1.04) < I 100 PCT. (Fct. 3.1.03)

Err. P05 ICUTOFF I: CUTOFF ON (Fct. 3.1.07) ~ CUTOFF OFF (Fct. 3.1.08)

Err. P06 FCUTOFF F: CUTOFF ON (Fct. 3.2.08) ~ CUTOFF OFF (Fct. 3.2.09)

Err. P09 F> 10 KHZ Frequency for Orno% > 10 kHz

Err. P10 PULS W/OTH Max. pulse width exceeded (see Fct. 3.2.05)

Err. P12 RNG./CUTOFF 2nd range of automatic range change (see Fct. 3.3.02):::; I CUTOFF ON (see Fct. 3.1.07)

Err. P14 I TRIP PT. I TRIP PT. (Fct. 3.3.03) outside range of current output (see Fct. 3.1.04)

E-List Description of error Rectify instrument fault Error output in measuring mode vi

Error messages and/or - Display (Fct. 2.04) and/or

clear error message - Status indication output (Fct. 3.3.0

dependent on programming

Display NO ADC TOT. ALL

Ist line* 2ndline MESS. ERROR ERROR ERROR

Err. E01 UNE /NT. Power failure since D - - yes yes

last programming reset totalizer(s) if necessary

Note: no counting during

power failure

Err. E02 TOTAL/ZER Counts lost or totalizer D - - yes yes

overflow

Note: totalizer was reset!

Err. E03 DISPLAY Numerical overflow of display Check data Fct. 2.0.0 - - - yes

Display Ist line: ------------------

Display 3rd line: note 'Y Marker!

Err. E04 EEPROM 1 Data error in EEPROM 1 Check instrurnent parameters ** * * * * * *

(parameters) 0

Err. E05 CAL. DATA Calibration data lost Recalibrate signal converter, ** * * ** **

please consult factory

Err. E06 EEPROM 2 Data error in EEPROM Z (totalizer) D - - yes yes

Note: totalizer deviation possible reset totalizer(s) if necessary

Err. E07 RAM Check-sum error in RAM 0 - - - yes

Err. EOB ROM Check-sum error in ROM 0 - - - yes

Err. E09 ADC ADC value overranged or 0 - yes - yes

ADC defective

Err. E12 FREQ.OUTP. F Frequency output overranged D - - - yes

If necess„ check data, Fct. 3.2.00

Err. E13 CUR.OUTP. I Current output overranged D - - - yes

If necess., check data, Fct. 3.1.00

Err. E14 EE1 EE2 Current calibration values Terminate programming mode ** ** * * **

EPPROM t+Z are different (press mkey 4x), values

(occurs only when pc board changed)

corrected automatically

Err. E16 FUSE FS fuse for power failure Fit new F5 fuse, ye_s*** yes*** yes*** yes

identification defective see Sect. 8.5

* When errors are displayed during the measuring mode, "a numeral" and "Err." will appear in the Ist line.

The numeral gives the nurnber of momentarily occurring errors that are displayed alternately with the actual measured value.

**

***

0

0

No output in measuring mode! With these errors, the signal converter is automatically in the programming mode.

No output via status indication output (Fct. 3.3.01)

Invoke and then terminate programming mode.

Keystrokes: 2 X c /2 X a /2 X l]I and 4 X l]I or 1 X l]I and 4 X l]I (dependent on programming in Fct. 4.02)

Invoke and then terminate programming mode.

Keystrokes: 2 X c /2 X a /2 X [il and 4 X [il or 1 X [il and 4 X [il (dependent on programming in Fct. 4.02)

Consult factory if these errors occur several times in succession.

Programming and function of keys (Sect. 4.3)

Table of programmable functions (Sect. 4.6)

Plausibility check, P-List (Sect. 4.5)

Error messages, E-List (Sect. 4.4)

The Sect. Nos. referred to in these Condensed Instructions

will be found in the SC 100 AS Installation and Operating Instructions

D

Page

Pages B +

Page

Page](https://image.slidesharecdn.com/dok-150713074349-lva1-app6892/85/Dok-46-320.jpg)

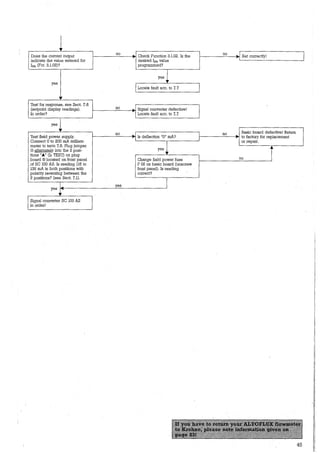

![1 7.6.3 Check of setpoint display

1. Switch on power source, allow at least 15 minutes'

warm-up ti_me.

2. Set switch D (front panel GS8) to "O" position.

3. Adjust zero with the 10-turn potentiometer P (front

panel GS8) to Io% ± < 10 µA.

4. Determine position of switch Y and setpoints I and f as

follows:

4.l X = 0100% *K * F

GK * DN2

0100%= full-scale range (100%)

in volumetric units (V)

per unit time (t)

GK = prirnary constant

(see prirnary head nameplate)

F = 2, if GK value

begins with "L"

= 1, GK value without L

DN = meter size in mm

or inches

=time in seconds (Sec.)

minutes (min), hours (hr)

V =volume

K = constant, see following Table

DN ~ Sec.

mm Liter 25464

m3 25464800

US gal 96396

inches Liter 39.47

m3 39470

US gal 149.4

4.2 Determine position of switch Y

min hr

424.4 7.074

424413 7074

1607 26.78

0.6578 0.0196

657.8 10.96

2.49 0.0415

Use table (front panel GS8) to determine the value Y which

comes closest to the factor X and meets condition Y ~ X.

4.3 Calculate setpoint reading CD current output

y

I = lo% + XCI100%-Io%) [mA]

Io% = current at 0% flowrate, see Fct. 3.1.02

(e.g. 4 mA, at 4 to 20 mA)

I100%= current at 100% flowrate, see Fct. 3.1.03

(e.g. 20 mA, at 014 to 20 mA)

4.4 Calculate setpoint reading (f) freguency output

y

f = x* f100% [HzJ

f10o% = pulses per second at 100% flowrate,

see Fct. 3.2.03

5. SetswitchD (frontpanel GS8) to position „+" or "-" (for-

li!ard or reverse floi'tl).

6. Set switch Y (front panel GS8) to the value determined

by the method described above.

7. Check setpoint readings I or f (see Points 4.3 and 4.4).

8. Deviation < 1.5% of setpoint! If greater, locate fault as

described in Sect. 7.5 + 7.7. First check field power

supply as described in Sect. 7.1.

9. Linearity test: adjust lower Yvalues, readings will drop

in proportion to the determined Yvalue (see Point 4.2).

10. Switch of power source after completing the test.

11. Disconnect GS8.

12. Reconnect leads of prirnary head.

13. Replace housing cover.

14. The system is ready for operation after the power

source has been switched on.

17.6.4 Example

Full scale range 0100% = 280m3/hr

(Fct. 1.01)

Meter size DN = 80 mm c~ 3")

(Fct. 1.05)

Current at Oo% Ioo/o = 4 mA (Fct. 3.1.02)

Current at 0 100% 1100% = 20 mA (Fct. 3.1.03)

Pulses at Owo% f100% = 280 pulses/hr