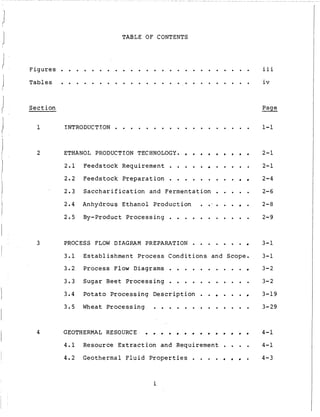

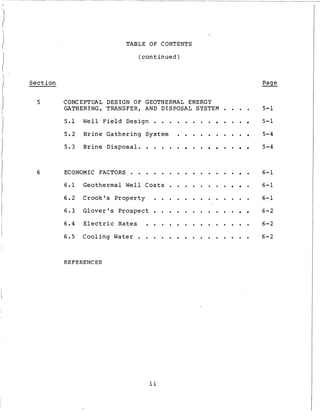

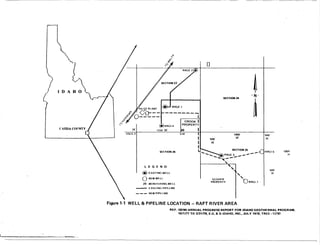

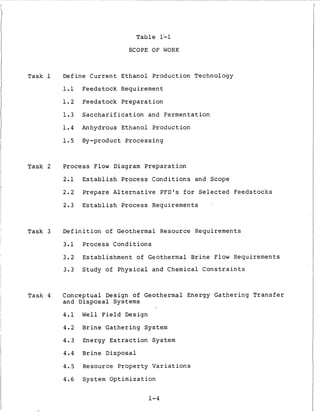

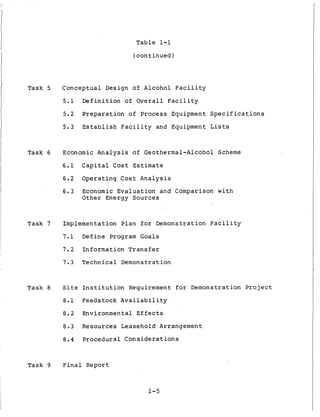

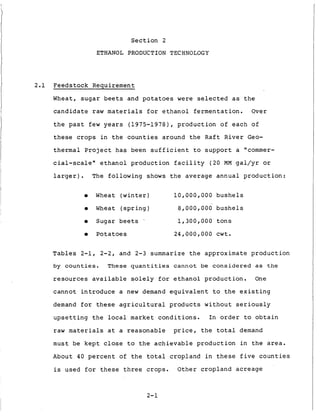

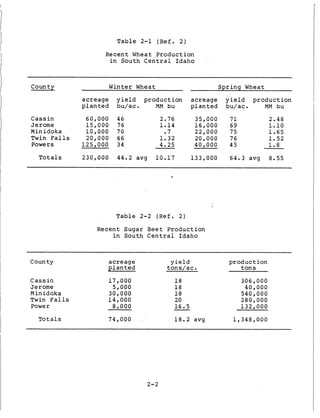

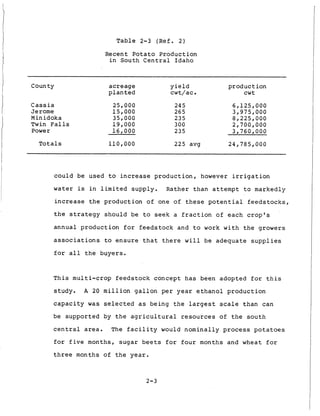

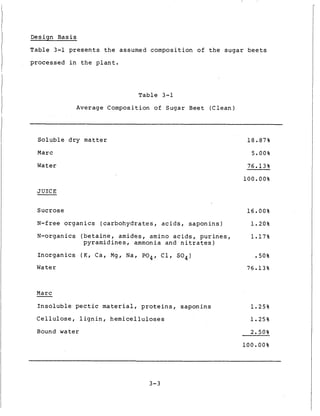

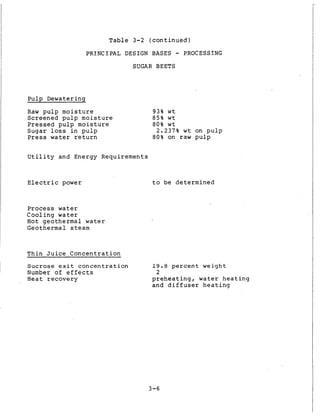

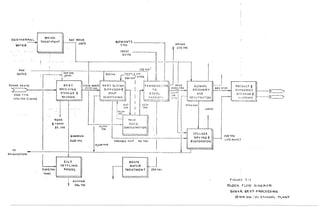

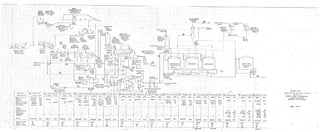

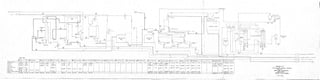

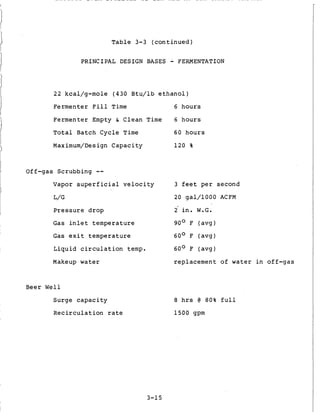

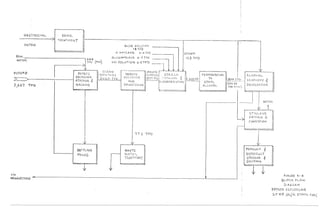

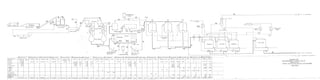

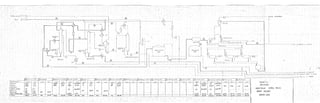

This document summarizes a study evaluating the production of ethanol from potatoes, sugar beets, and wheat using geothermal resources in Idaho. A 20 million gallon per year ethanol plant is proposed that would operate nominally for 5 months on potatoes, 4 months on sugar beets, and 3 months on wheat. Process flow diagrams are being developed for each feedstock. Geothermal fluid at 280°F would provide heat for conventional ethanol production technology. Wells drilled in a grid pattern would supply the geothermal resource to minimize scale deposition. Economic factors such as well costs, electricity rates, and cooling water availability are also considered.