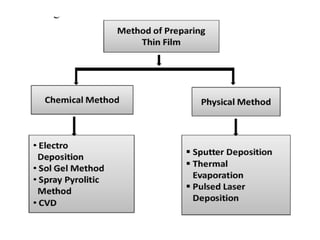

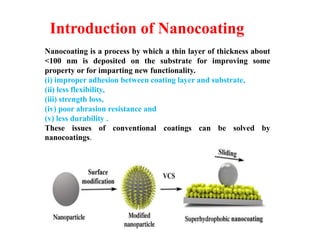

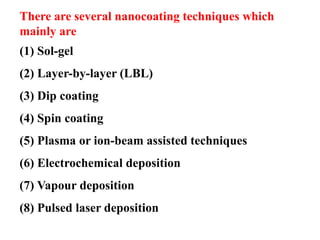

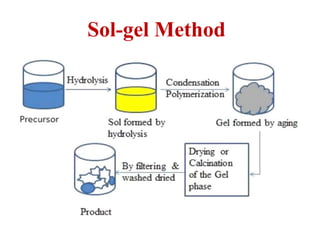

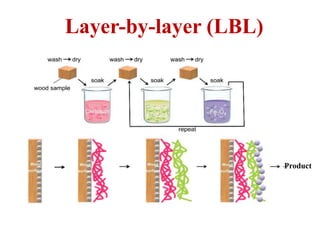

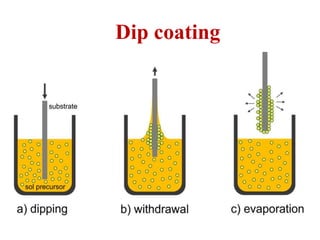

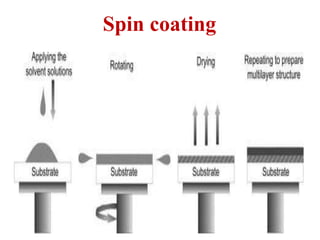

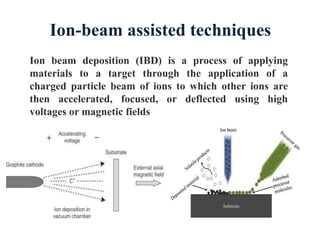

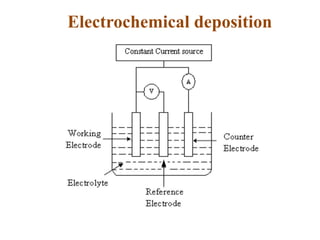

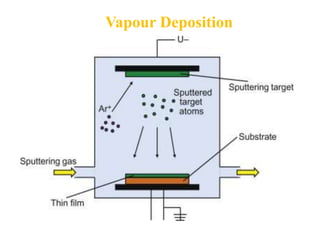

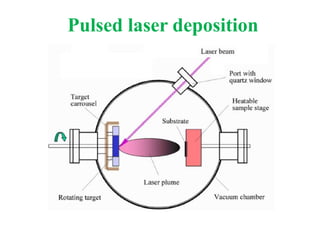

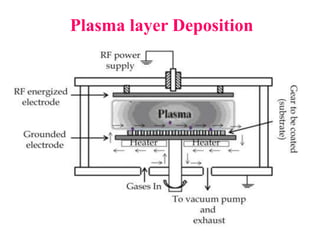

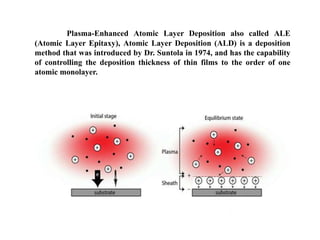

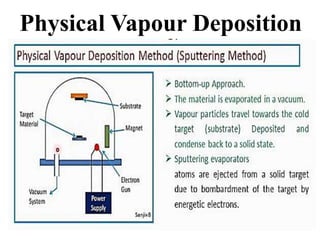

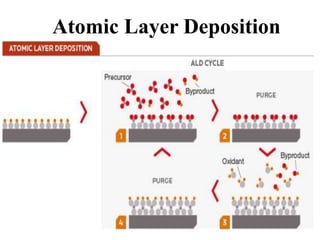

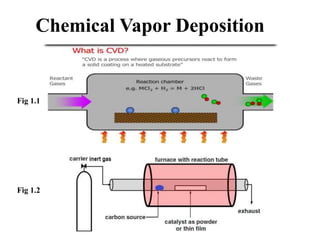

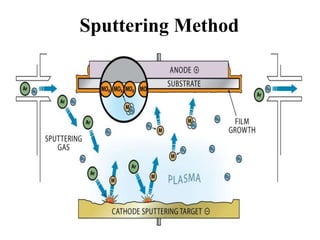

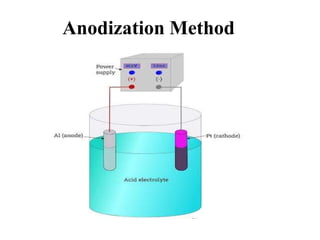

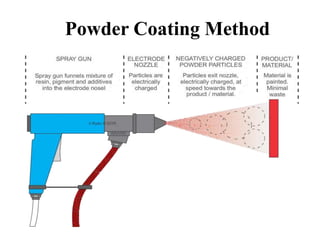

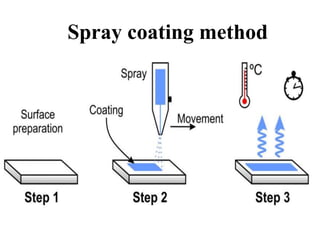

Nanocoating involves depositing a thin layer less than 100 nm thick onto a substrate to improve or add new properties. Conventional coatings can have issues like poor adhesion, flexibility, strength, abrasion resistance and durability, but nanocoatings can solve these issues. Common nanocoating techniques include sol-gel, layer-by-layer deposition, dip coating, spin coating, plasma-assisted deposition, electrochemical deposition, vapor deposition, and pulsed laser deposition. Nanocoatings have various applications including self-cleaning, depolluting, UV protection, anticorrosion, insulation, water sheeting and beading, antifouling, and anti-graffiti coatings.