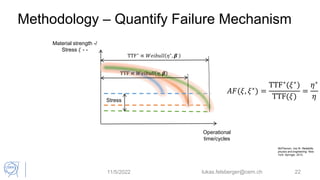

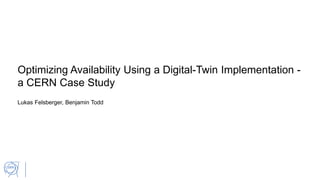

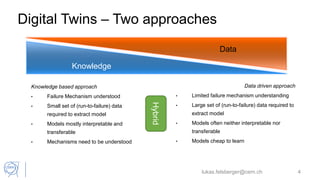

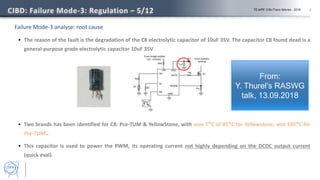

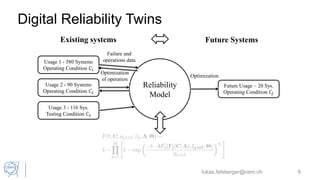

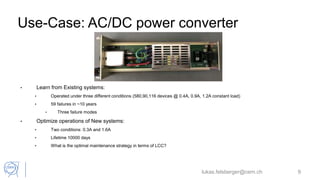

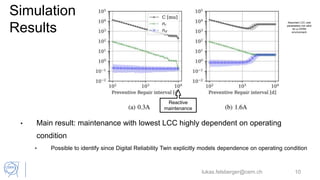

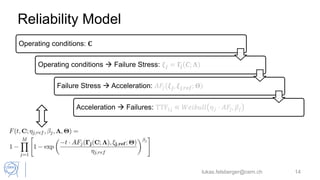

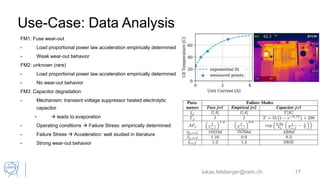

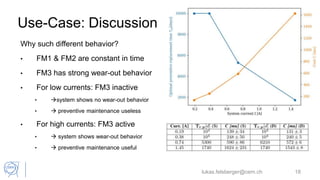

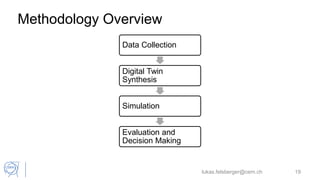

The document discusses using a digital twin approach to optimize availability for complex systems like electronics. It describes two main approaches - a knowledge-based one using limited failure data and models, and a data-driven one requiring large failure datasets. The case study presented learns from failure data of existing power converters under different usage conditions to build a reliability model. This allows simulating optimal maintenance strategies for new converters operating under different conditions to minimize life cycle costs. Criticism notes the approach may be difficult with limited early data, and emphasizes reliability testing and knowledge reuse.

![Introduction - Availability

The proportion of time a unit U is in a functional state

• 𝐴𝑣𝑎𝑖𝑙𝑎𝑏𝑖𝑙𝑖𝑡𝑦 =

𝐸[𝑈𝑝𝑡𝑖𝑚𝑒]

𝐸[𝑈𝑝𝑡𝑖𝑚𝑒]+𝐸[𝐷𝑜𝑤𝑛𝑡𝑖𝑚𝑒]

11/5/2022 lukas.felsberger@cern.ch 20

U

I O

E](https://image.slidesharecdn.com/digittwin-221105162156-34033850/85/digit_twin-pptx-20-320.jpg)