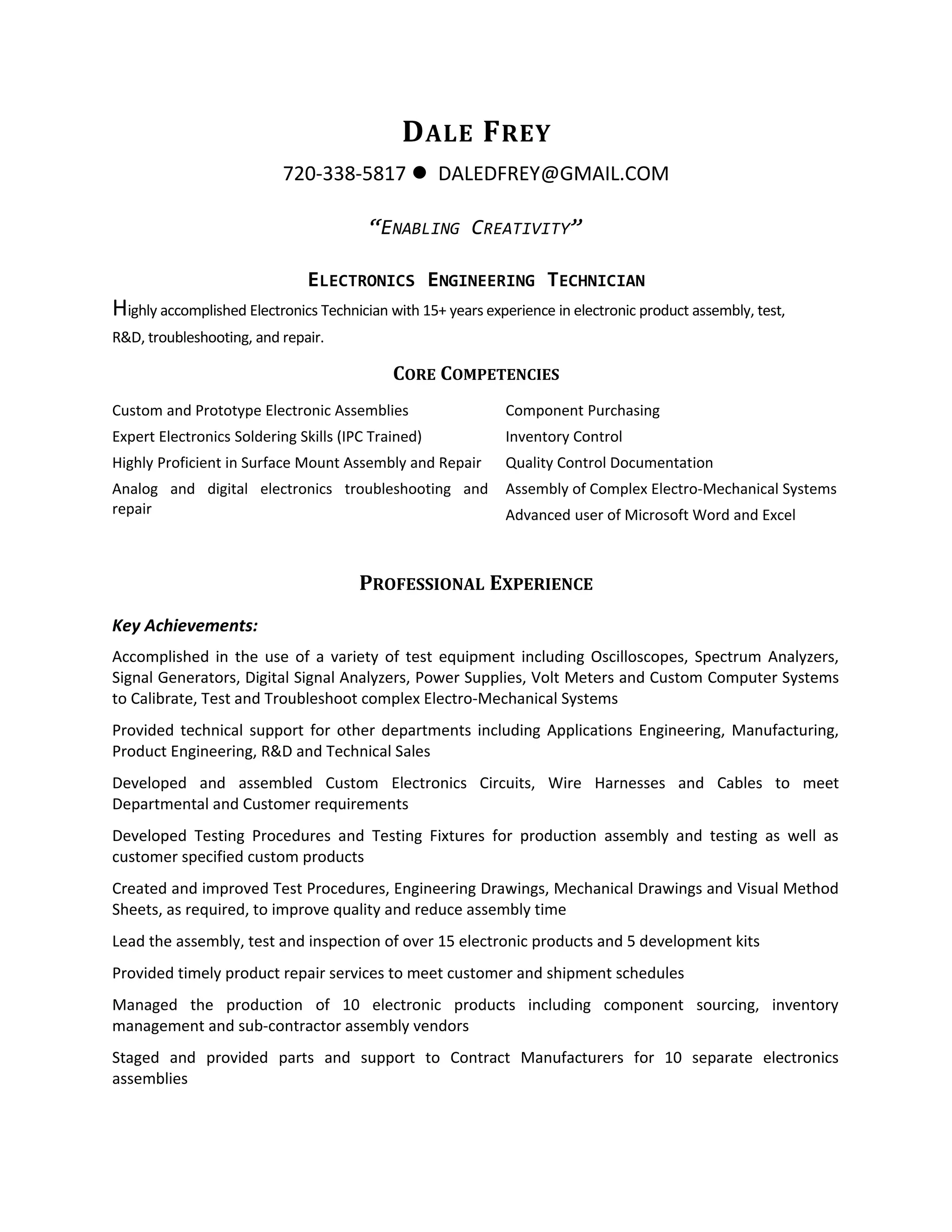

Dale Frey is an experienced Electronics Engineering Technician with over 15 years of experience in electronics assembly, testing, troubleshooting, and repair. He has expertise in custom electronic assemblies, soldering, surface mount assembly, analog and digital troubleshooting. At his current role at Creation Technologies, he assists with the development, assembly, and testing of new electronic products. Previously, he worked at Infinite Power Solutions as an Electro-Mechanical Technician, where he helped manufacture thin film lithium ion batteries.