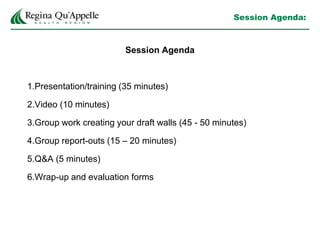

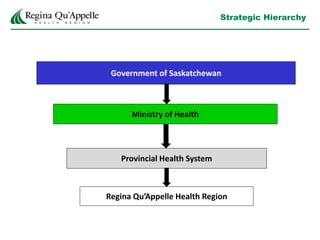

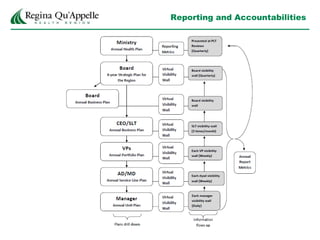

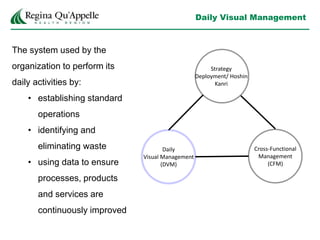

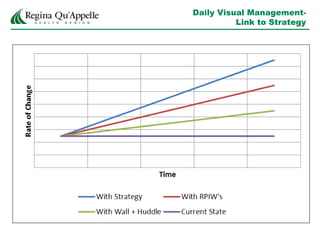

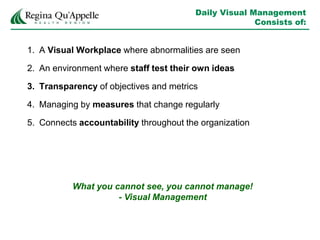

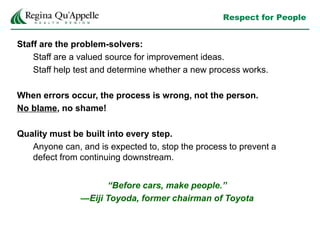

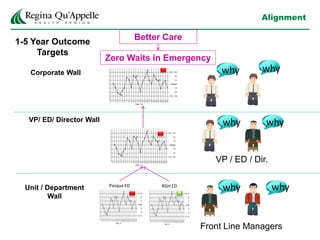

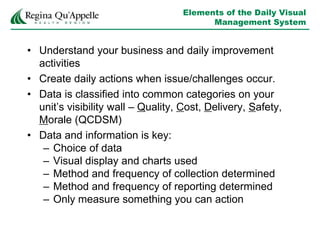

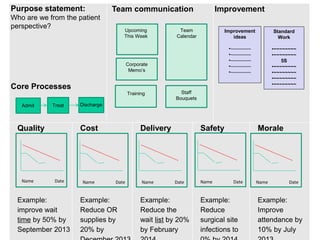

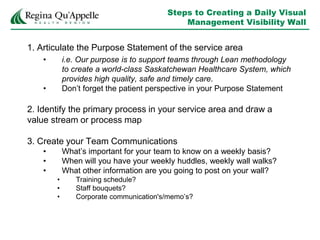

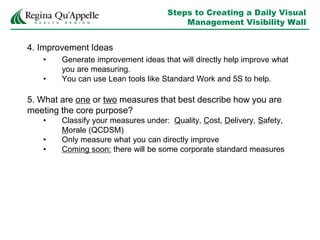

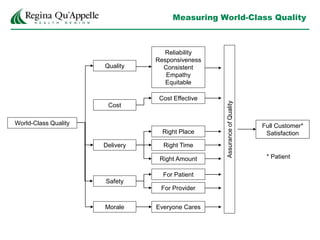

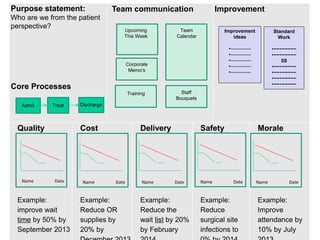

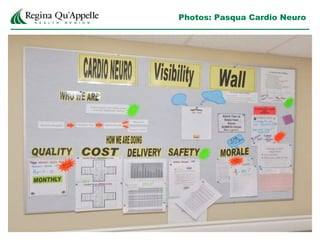

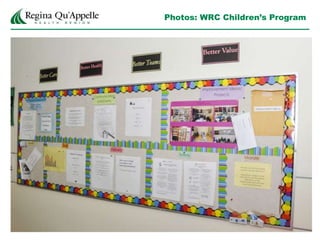

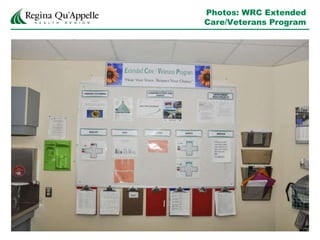

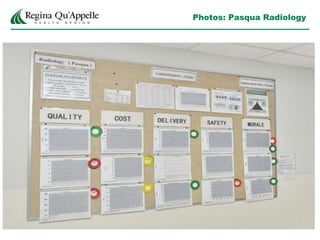

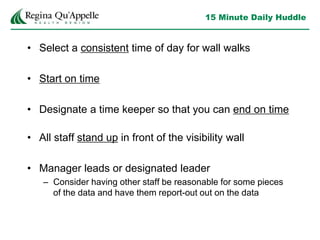

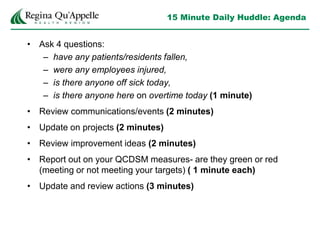

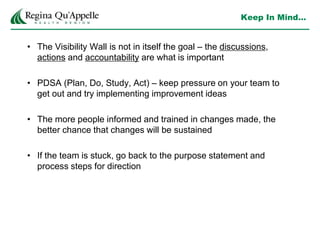

The document outlines a training session agenda for implementing daily visual management (DVM) in the healthcare context, focusing on establishing standard operations and promoting continuous improvement through visual tools. It emphasizes the importance of employee involvement in problem-solving, setting measurable targets across various categories such as quality, cost, delivery, safety, and morale. Effective communication and accountability through structured team interactions and visible performance metrics are highlighted as critical components for fostering a culture of improvement in the organization.