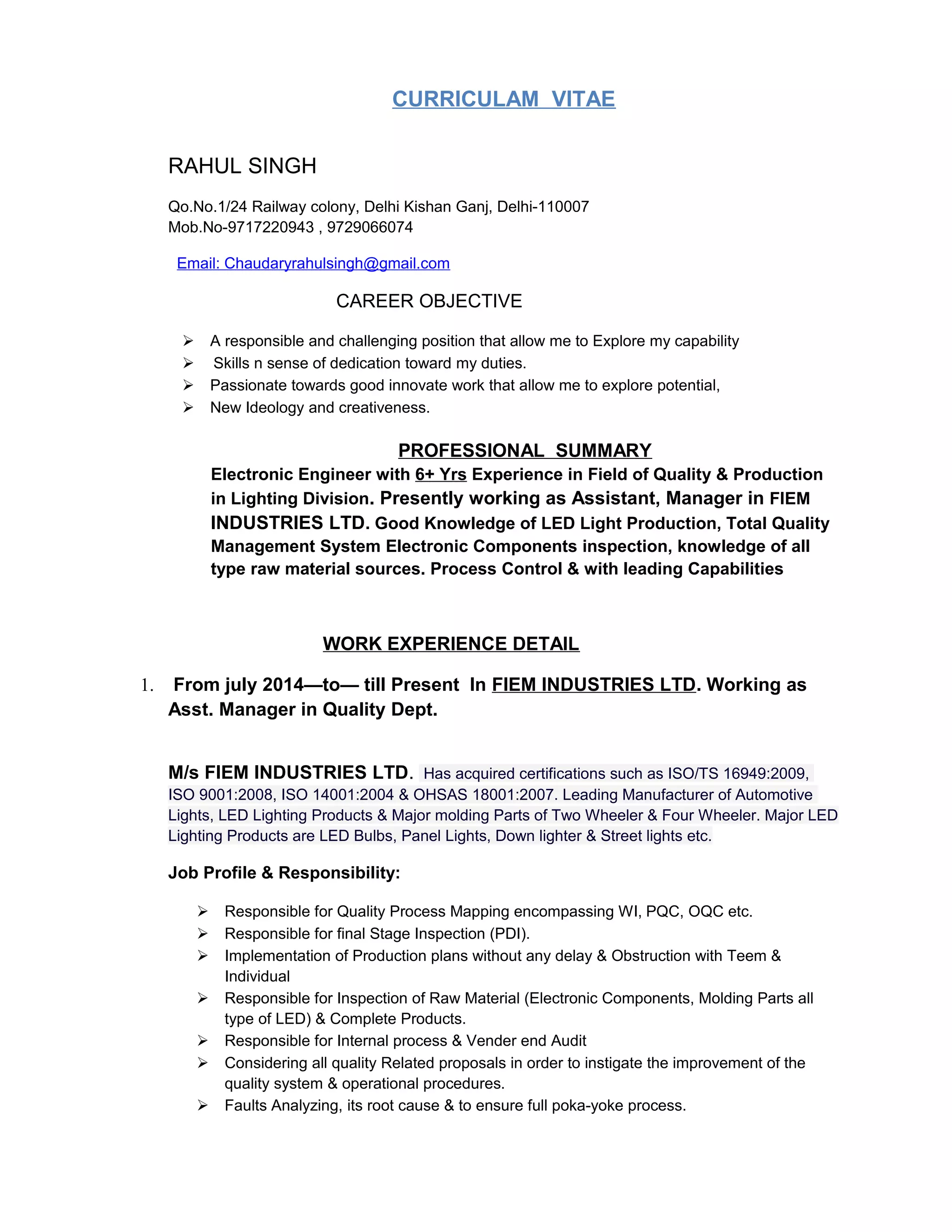

Rahul Singh is seeking a responsible and challenging position that allows him to explore his capabilities. He has over 6 years of experience in quality and production roles in the lighting industry. Currently he works as an Assistant Manager at FIEM INDUSTRIES LTD, where he is responsible for quality processes, inspection of materials and products, internal audits, and continuous improvement projects. He holds a B.Tech in Electronics and Communication from U.P. Technical University Lucknow.