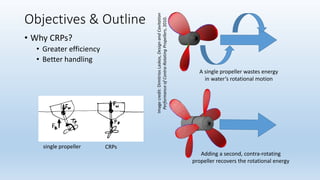

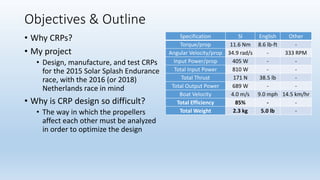

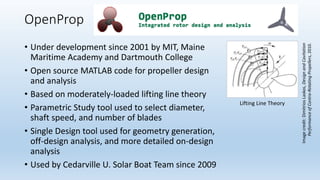

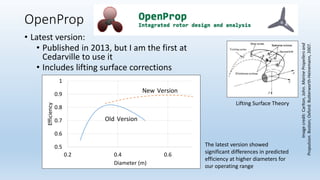

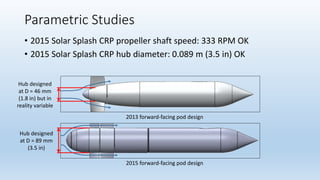

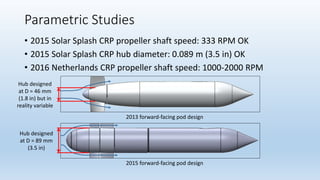

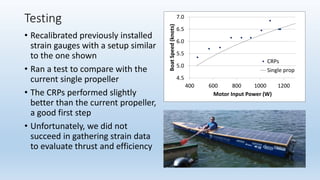

The document summarizes the design and testing of contra-rotating propellers (CRPs) for a solar-powered boat. It describes modifying an open-source propeller design program called OpenProp to model CRPs, parametric studies to select propeller dimensions, manufacturing the CRP system using a CNC mill, and preliminary testing that showed a 3% improvement in efficiency over a single propeller. The overall goal was to design, build, and test CRPs for an upcoming solar boat race.