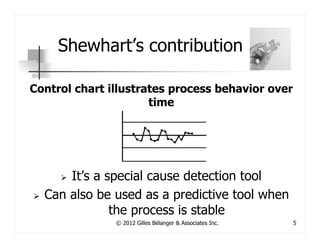

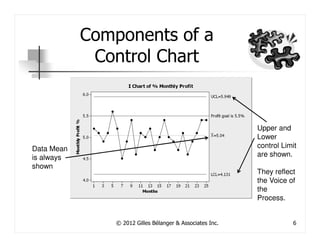

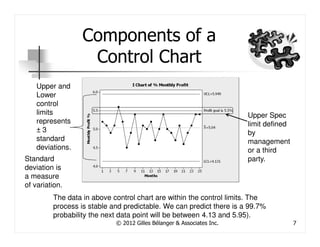

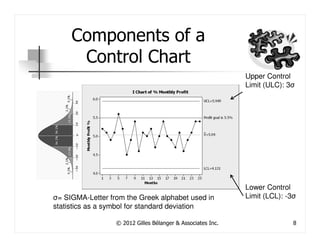

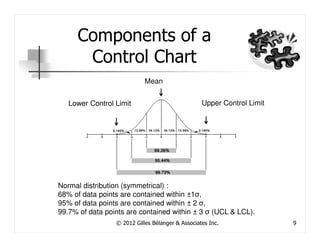

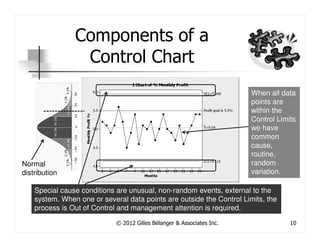

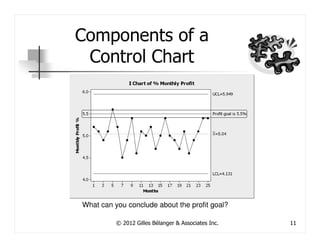

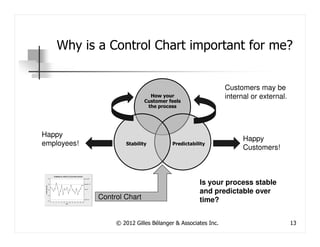

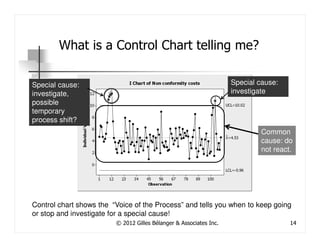

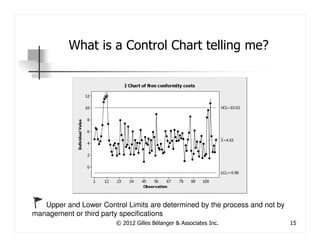

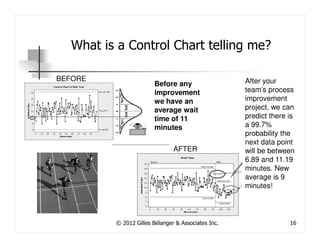

This document summarizes a workshop on control charts for management. The workshop will teach participants how to interpret control charts and explain their benefits. Control charts were invented in the 1920s to distinguish between common and special causes of variation in processes. The workshop will cover the components and interpretation of control charts, why they are important for monitoring processes, and how they benefit management by showing when processes are stable or in need of intervention.