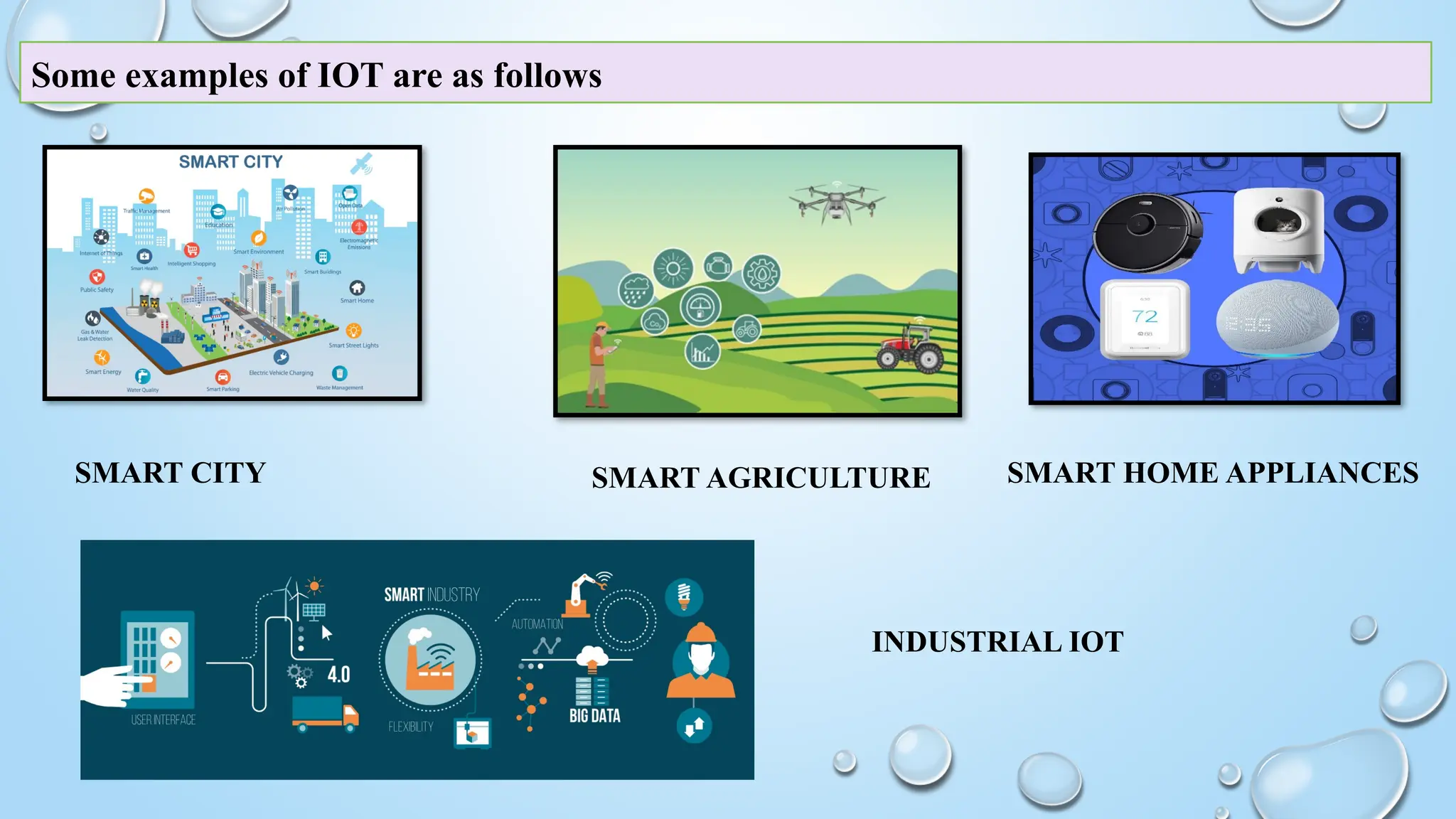

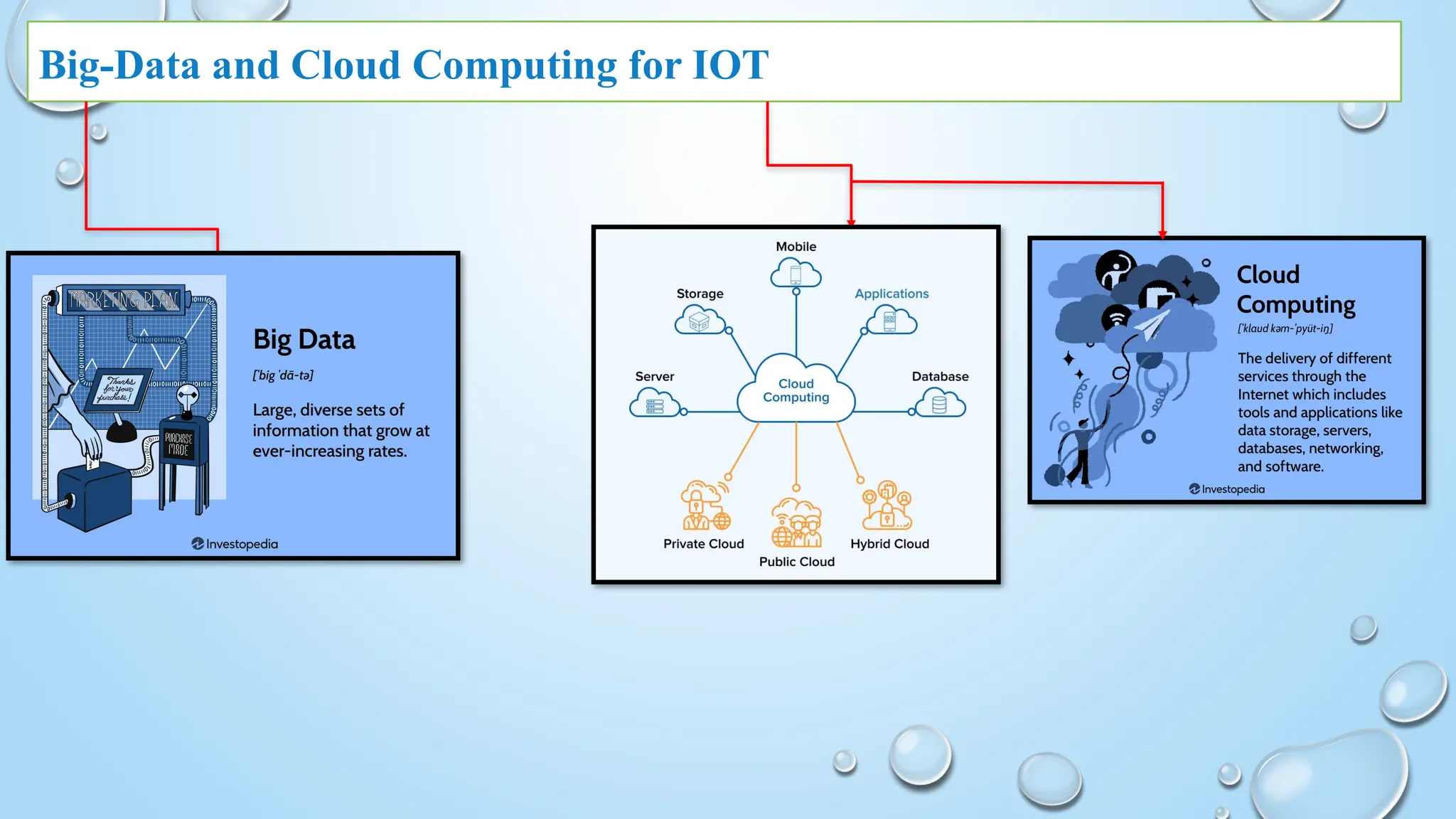

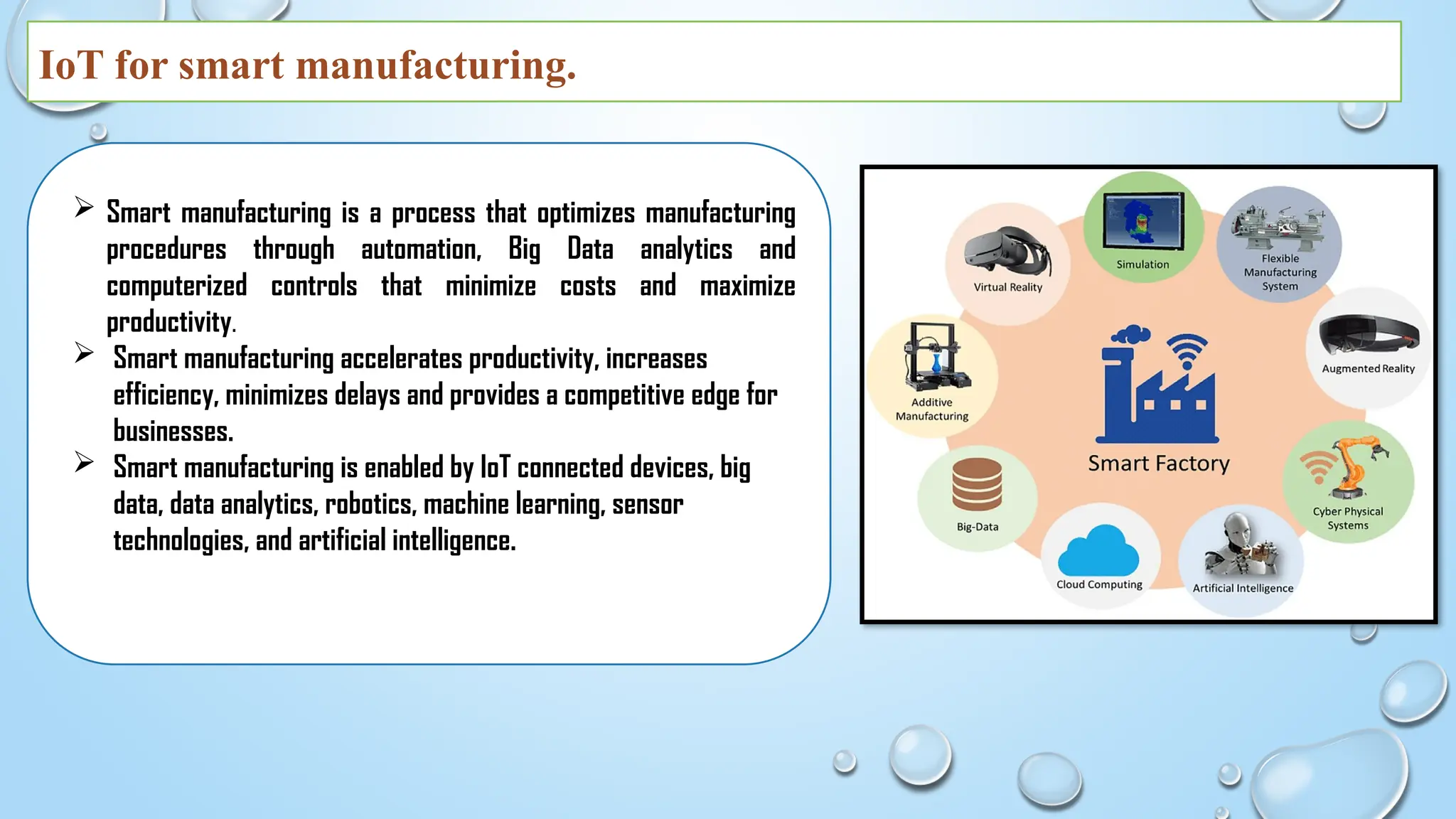

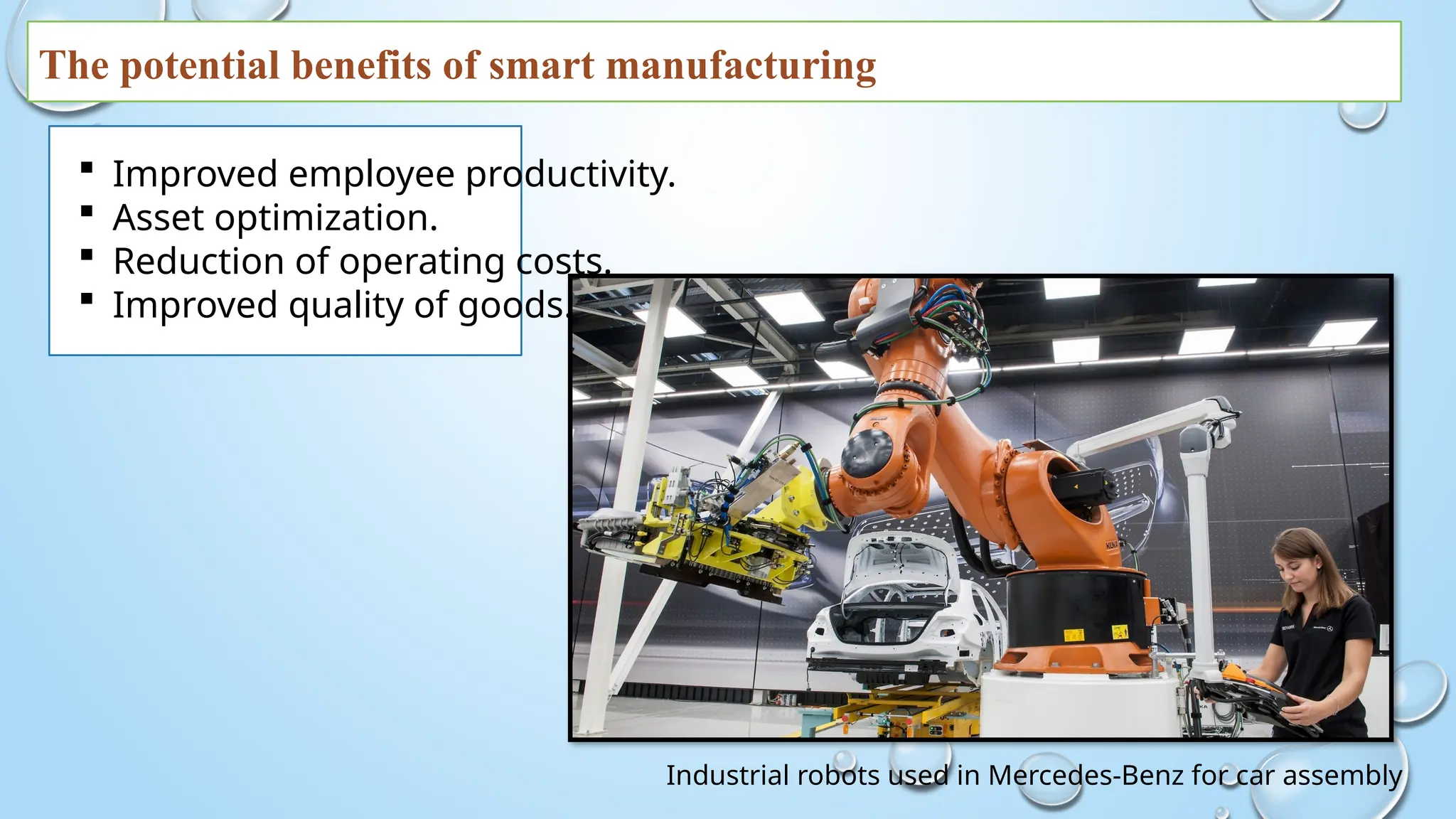

The document discusses the Internet of Things (IoT) and its applications across various sectors, emphasizing its role in smart manufacturing and industrial automation. It highlights how IoT enables devices to connect and share data without human intervention, leading to improved efficiency, reduced costs, and better productivity. The potential benefits of integrating IoT in manufacturing include enhanced employee productivity, asset optimization, and predictive maintenance.