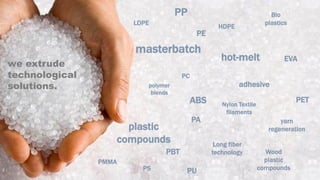

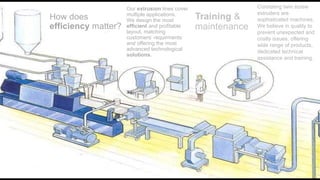

COMAC is an Italian company that has been developing extrusion technology for plastics since 1978. They produce twin screw extruders and specialized equipment for processing polymers and plastic compounds. COMAC works with customers to design efficient and profitable extrusion lines tailored to their needs and applications. Their goal is to offer advanced technological solutions and expertise in extrusion processing.