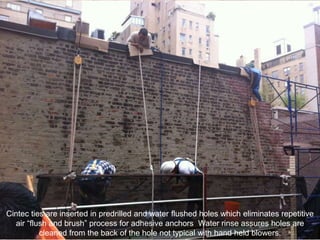

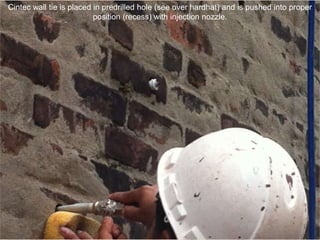

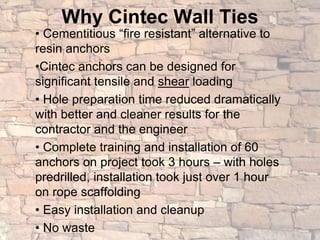

Cintec fire-rated wall ties are being used as an alternative to adhesive wall ties in New York City construction projects according to NYC Buildings Bulletin 2012-007. Cintec ties are inserted into predrilled holes using water flushing which eliminates the need for air flushing and brushing required for adhesive anchors. Cintec ties are supplied with a cementitious grout and are placed wetted in predrilled holes for later grout injection. The installation of Cintec ties is faster than adhesive anchors with cleaner results and less waste.