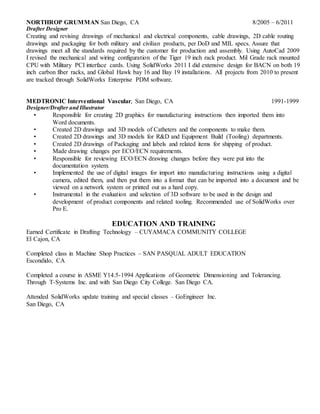

Daniel Chesser has over 20 years of experience as a drafter and designer for various industries including aerospace, medical devices, agriculture, automotive, and more. He has extensive knowledge of drafting standards and practices as well as software such as AutoCAD, SolidWorks, PTC Creo, Windchill, and Teamcenter. His background includes creating 2D drawings, 3D models, and ensuring documentation meets all required standards.