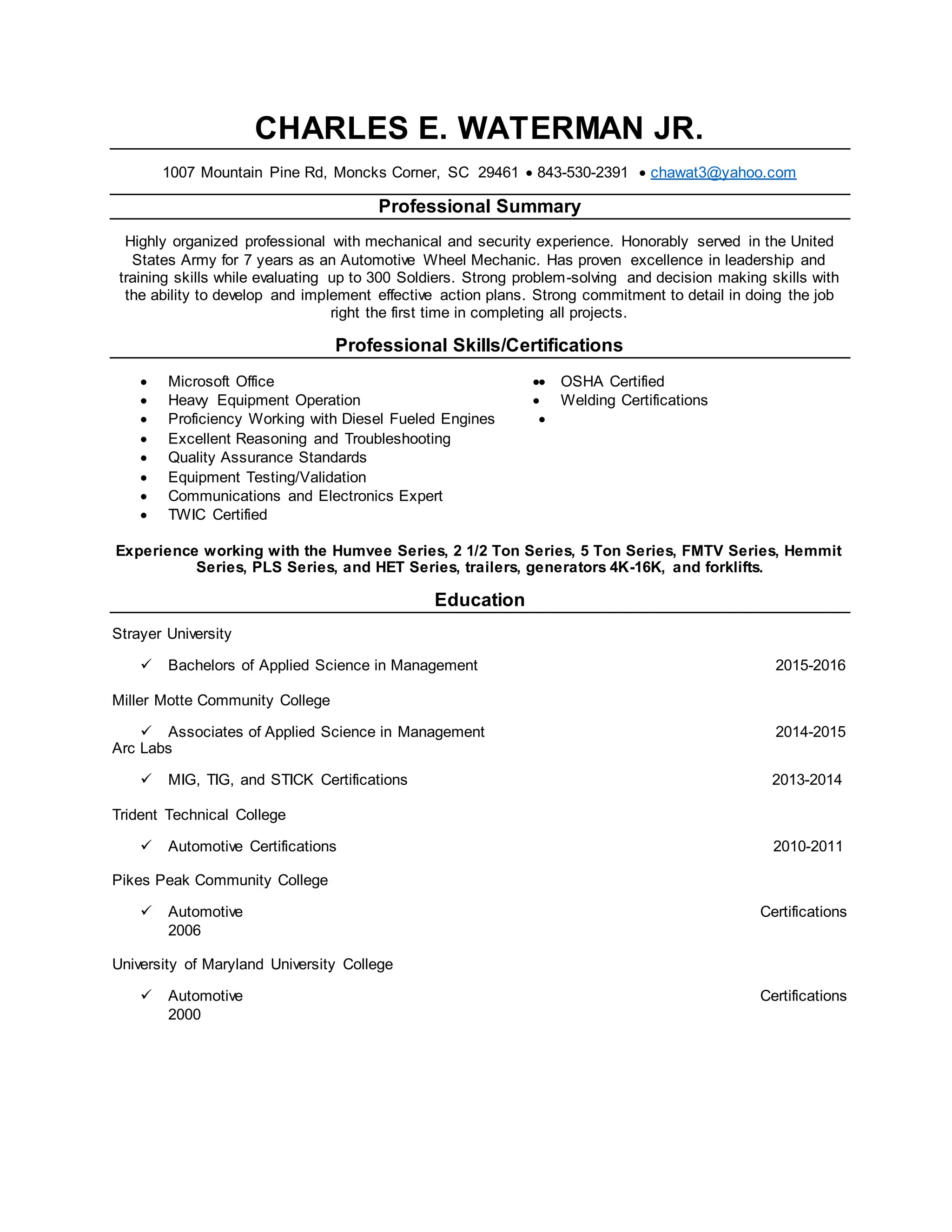

Charles Waterman has over 20 years of experience as an automotive and heavy wheeled vehicle mechanic. He honorably served 7 years in the US Army as an automotive wheel mechanic, where he evaluated up to 300 soldiers. He has worked as a heavy wheeled vehicle mechanic for Honeywell International and Dyncorp International, where he maintained and repaired diesel engines. Waterman holds various welding and automotive certifications and a bachelor's degree in management.