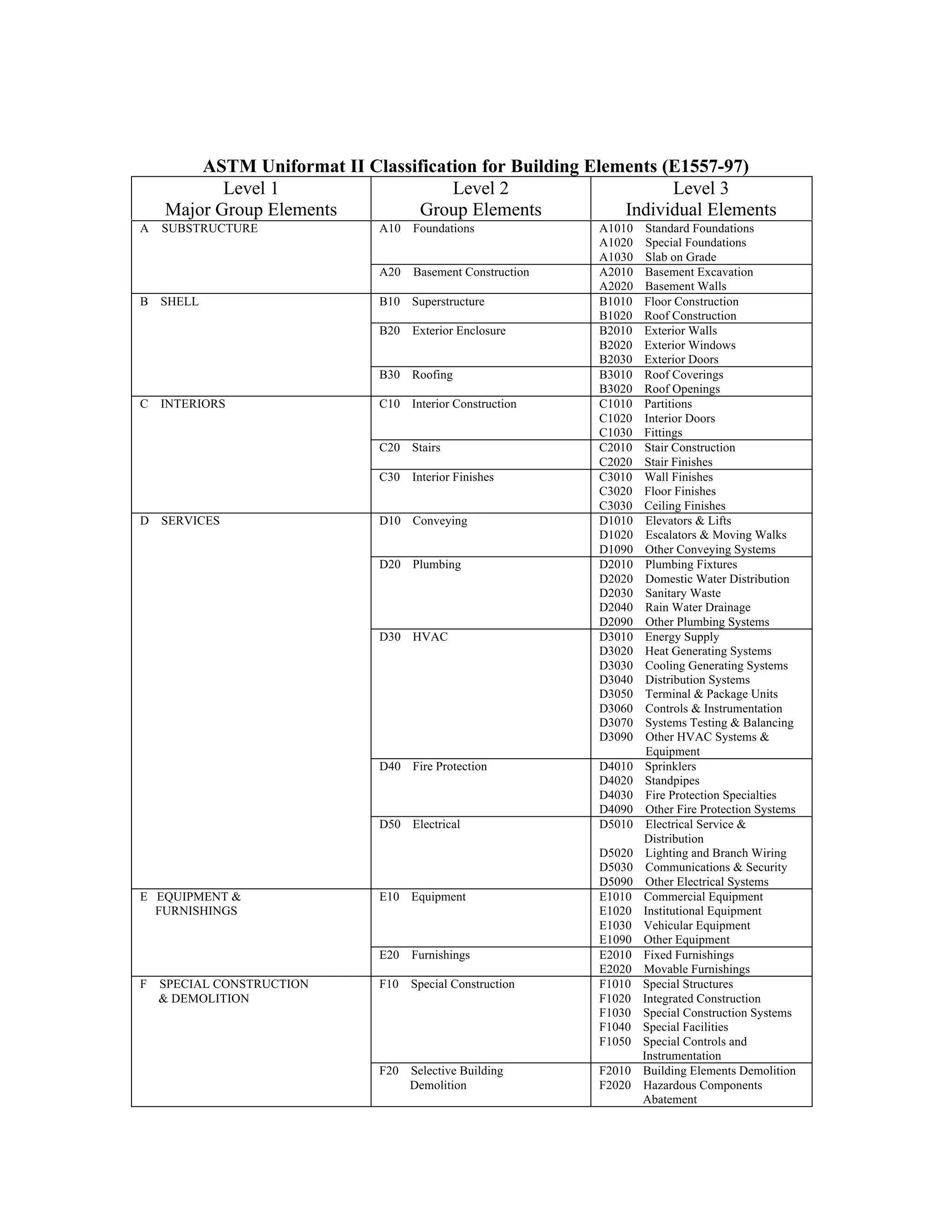

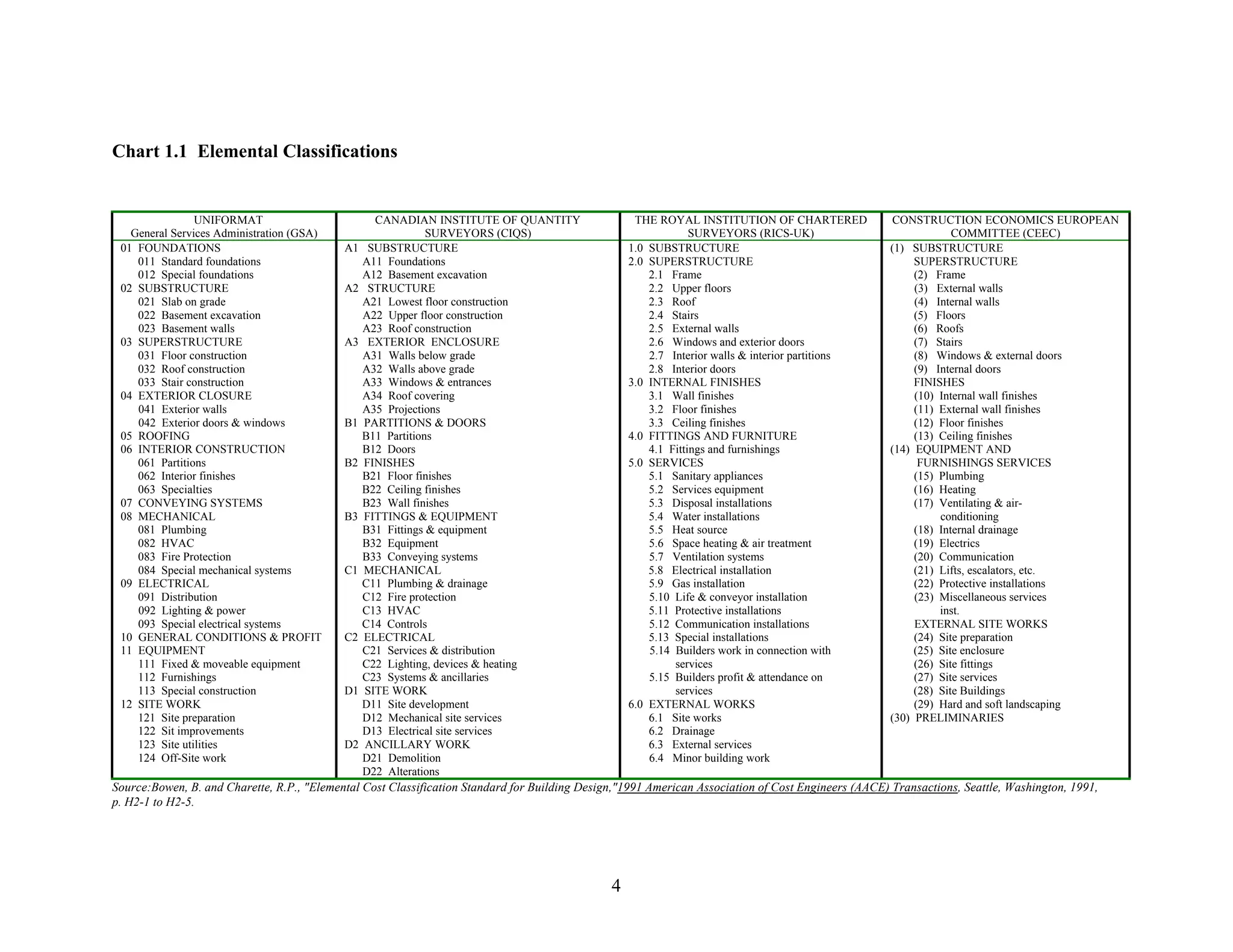

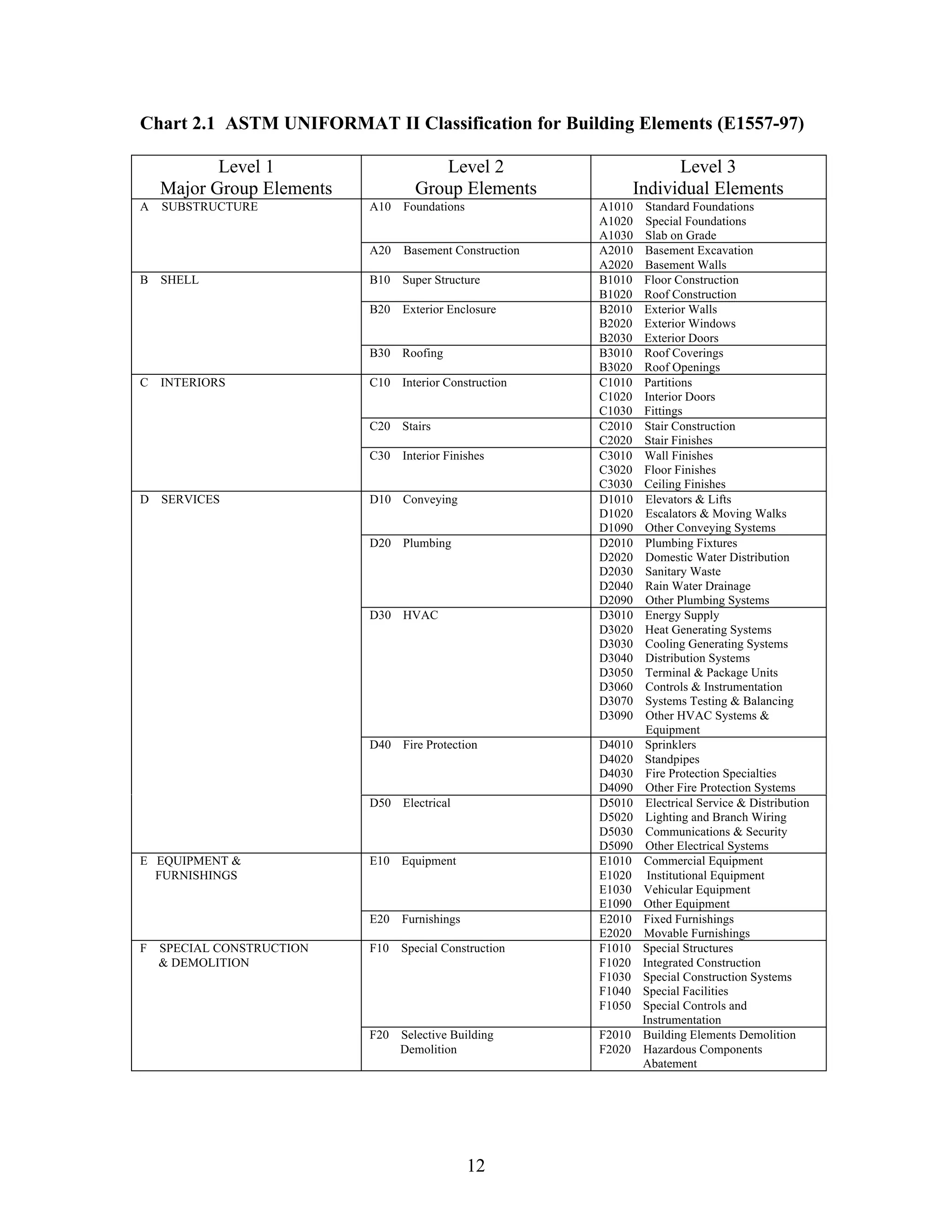

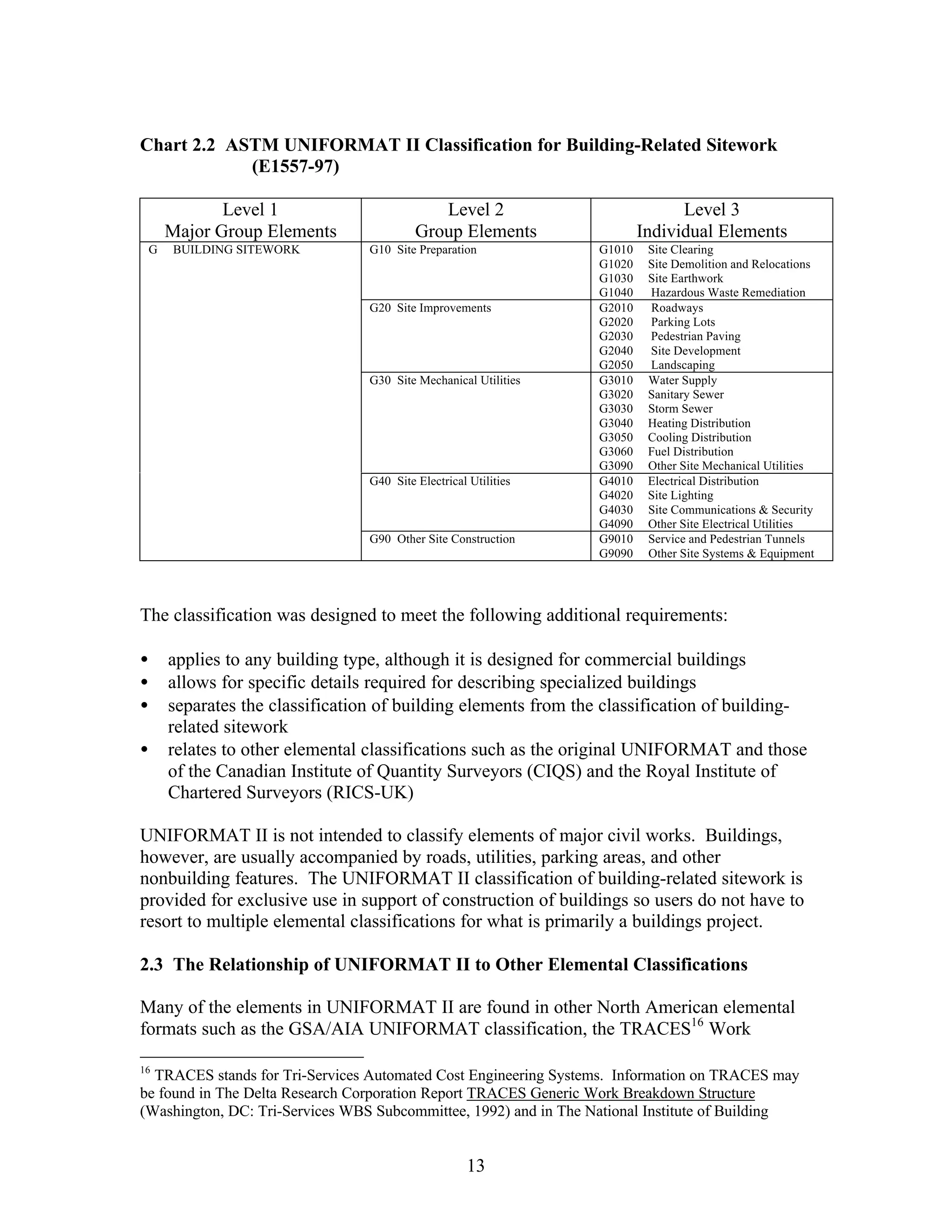

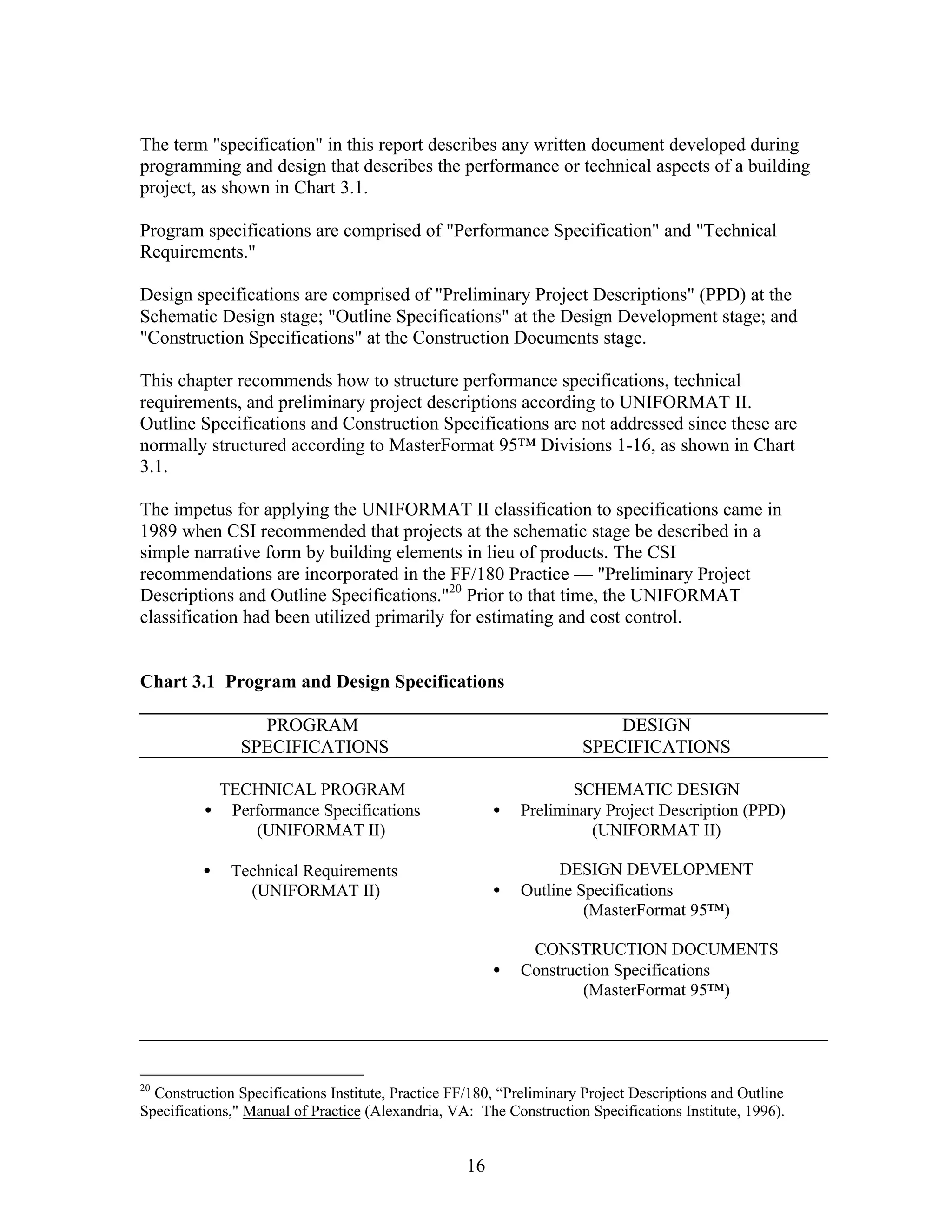

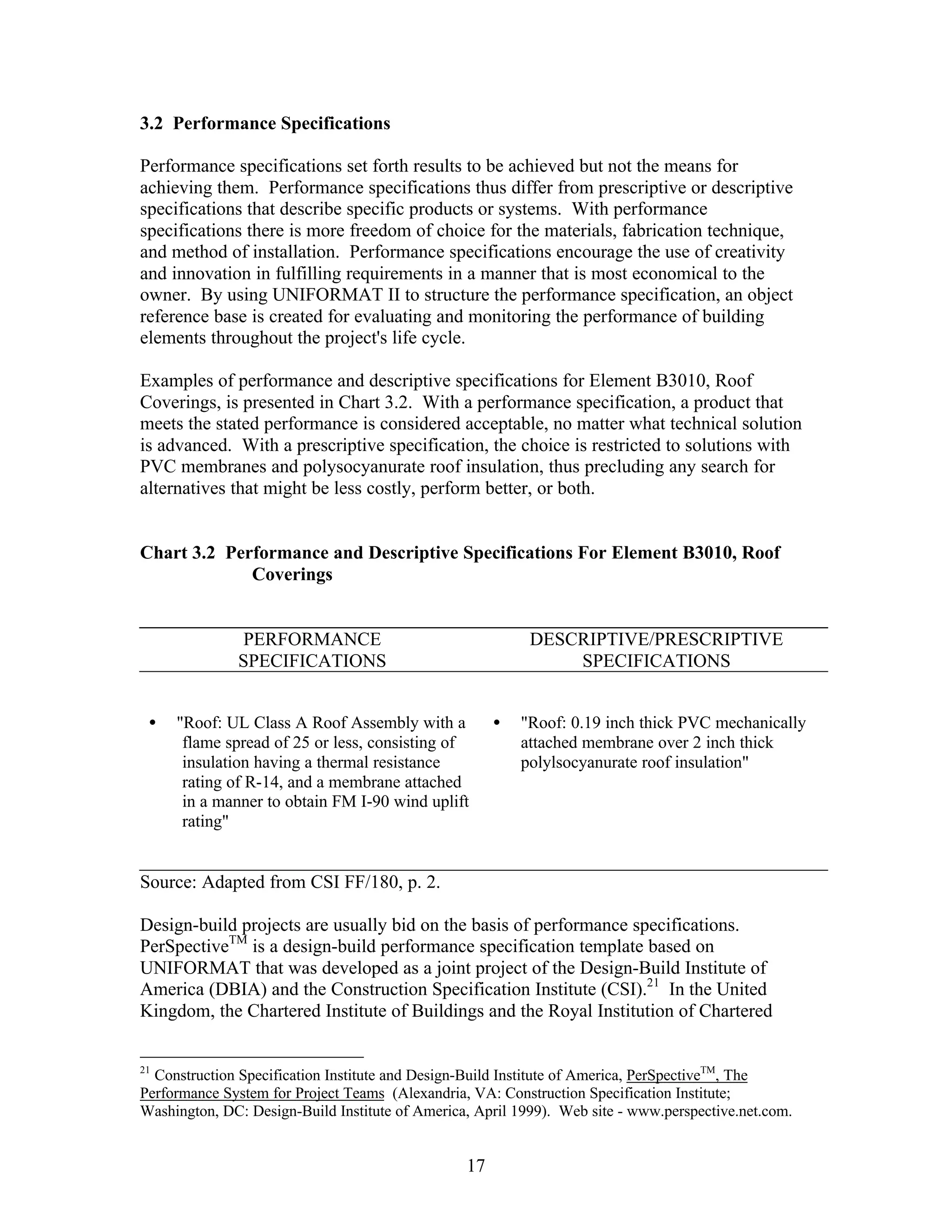

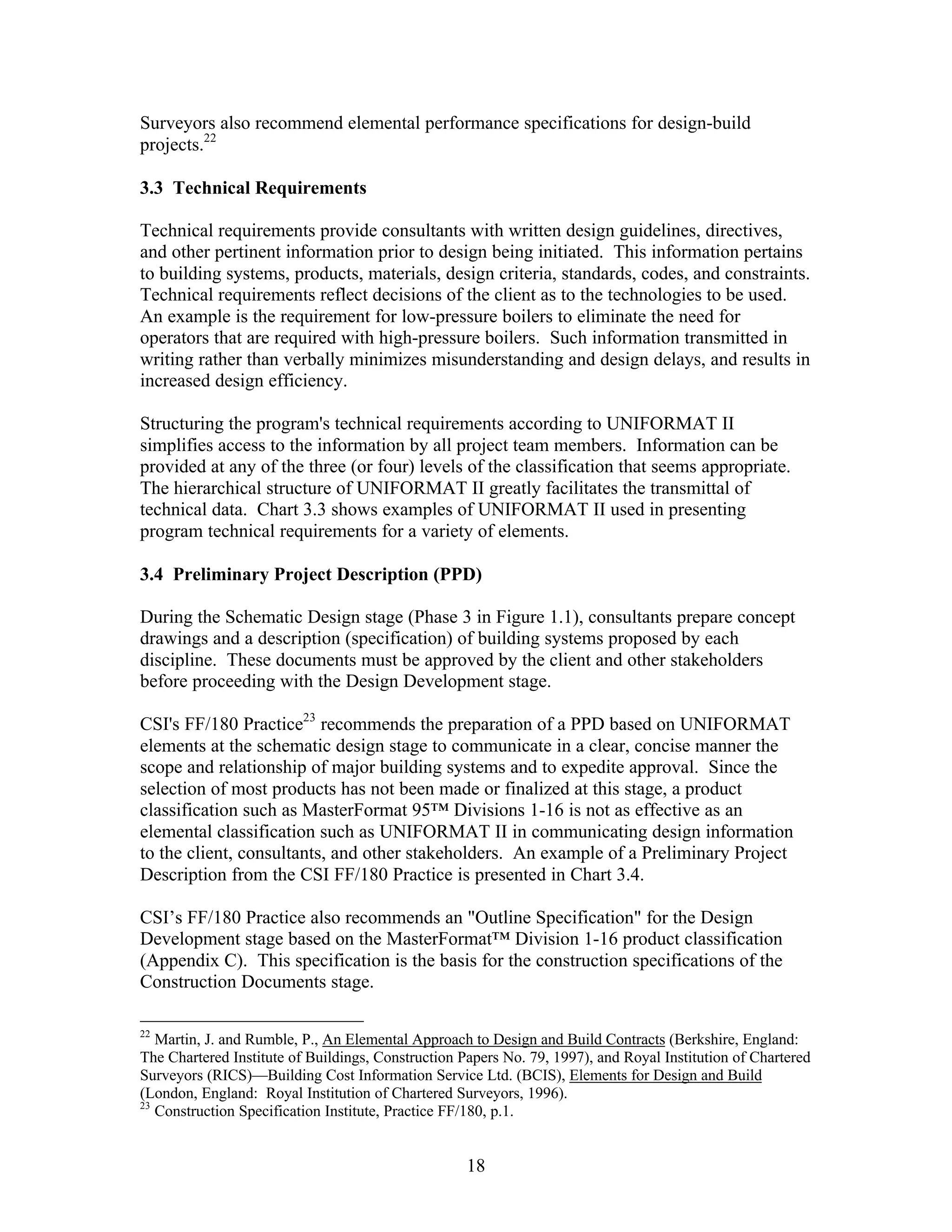

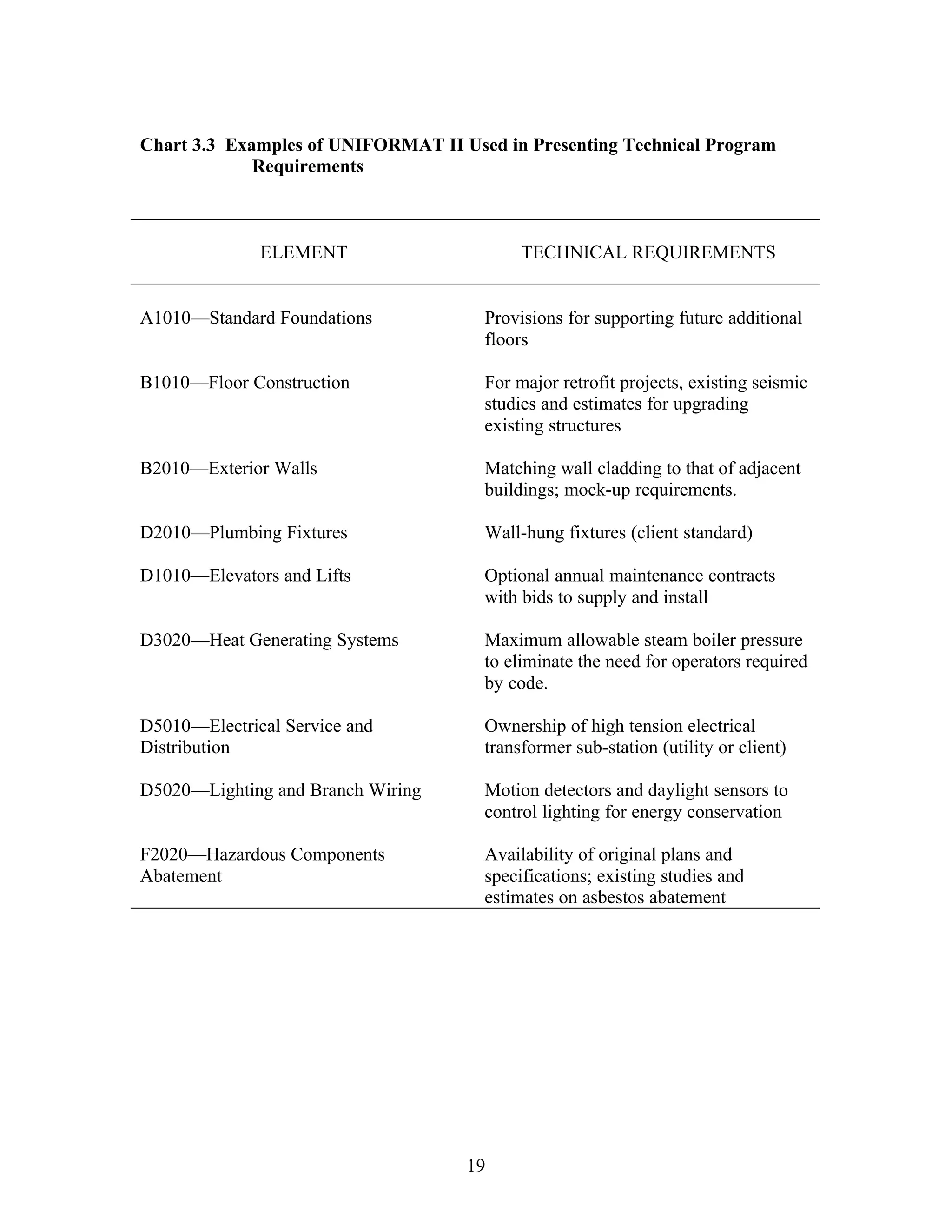

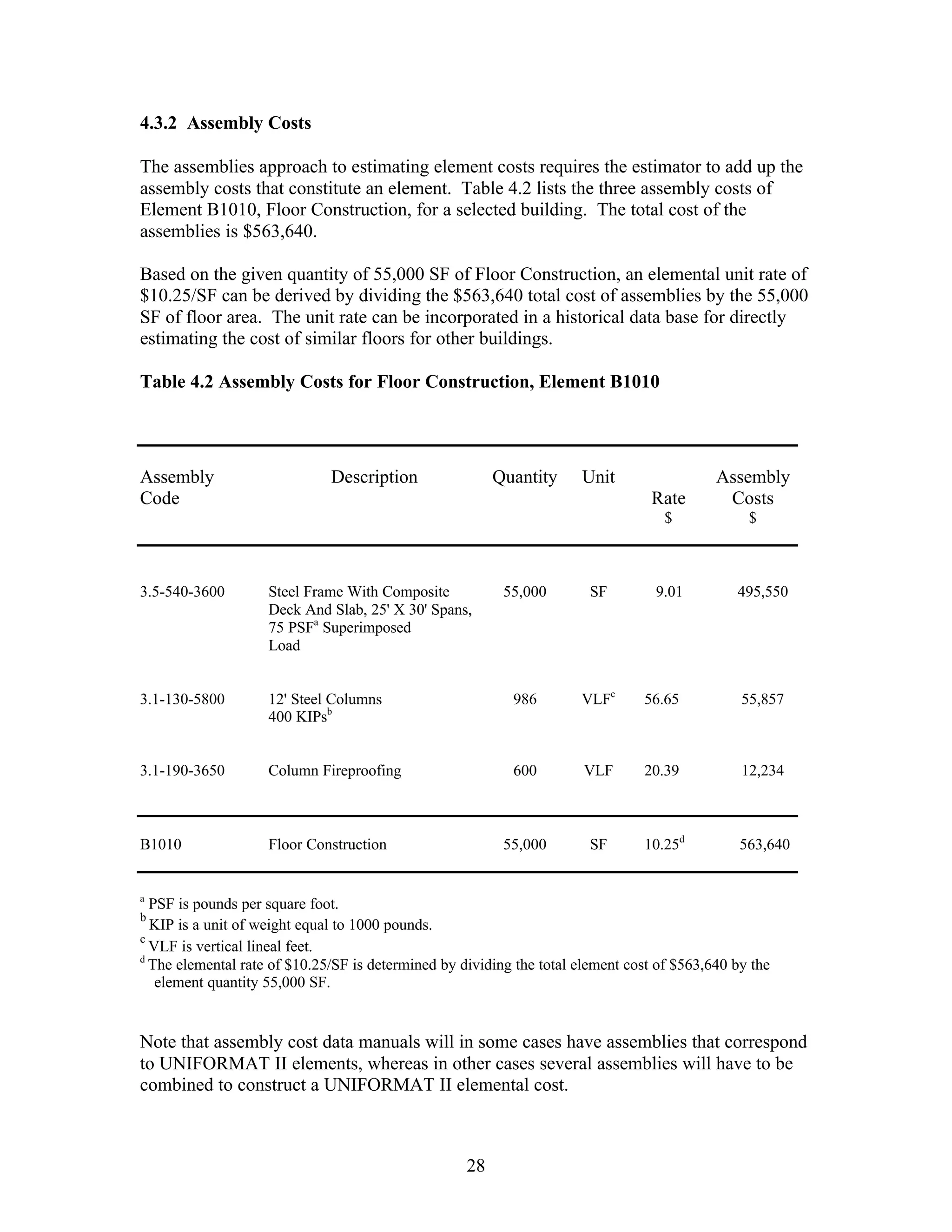

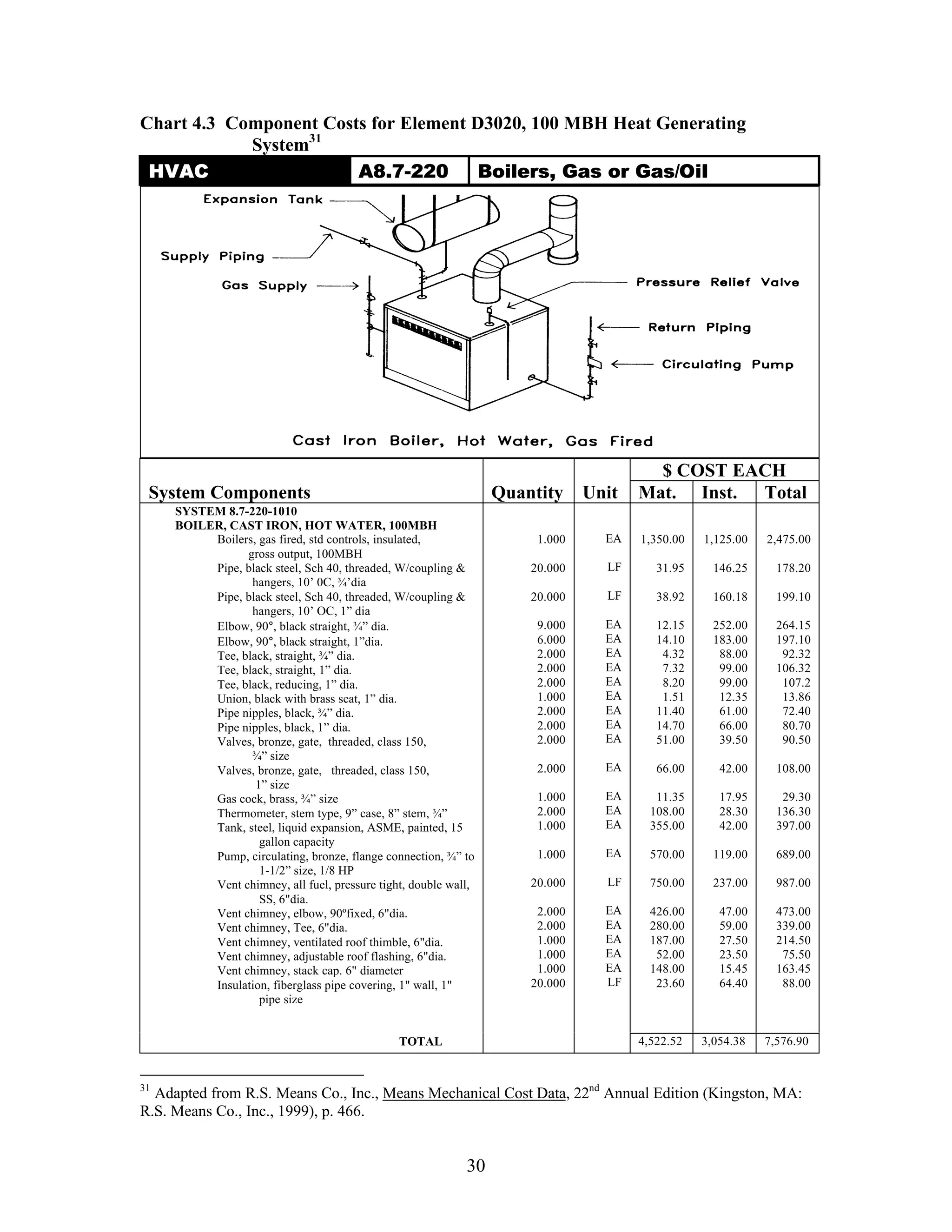

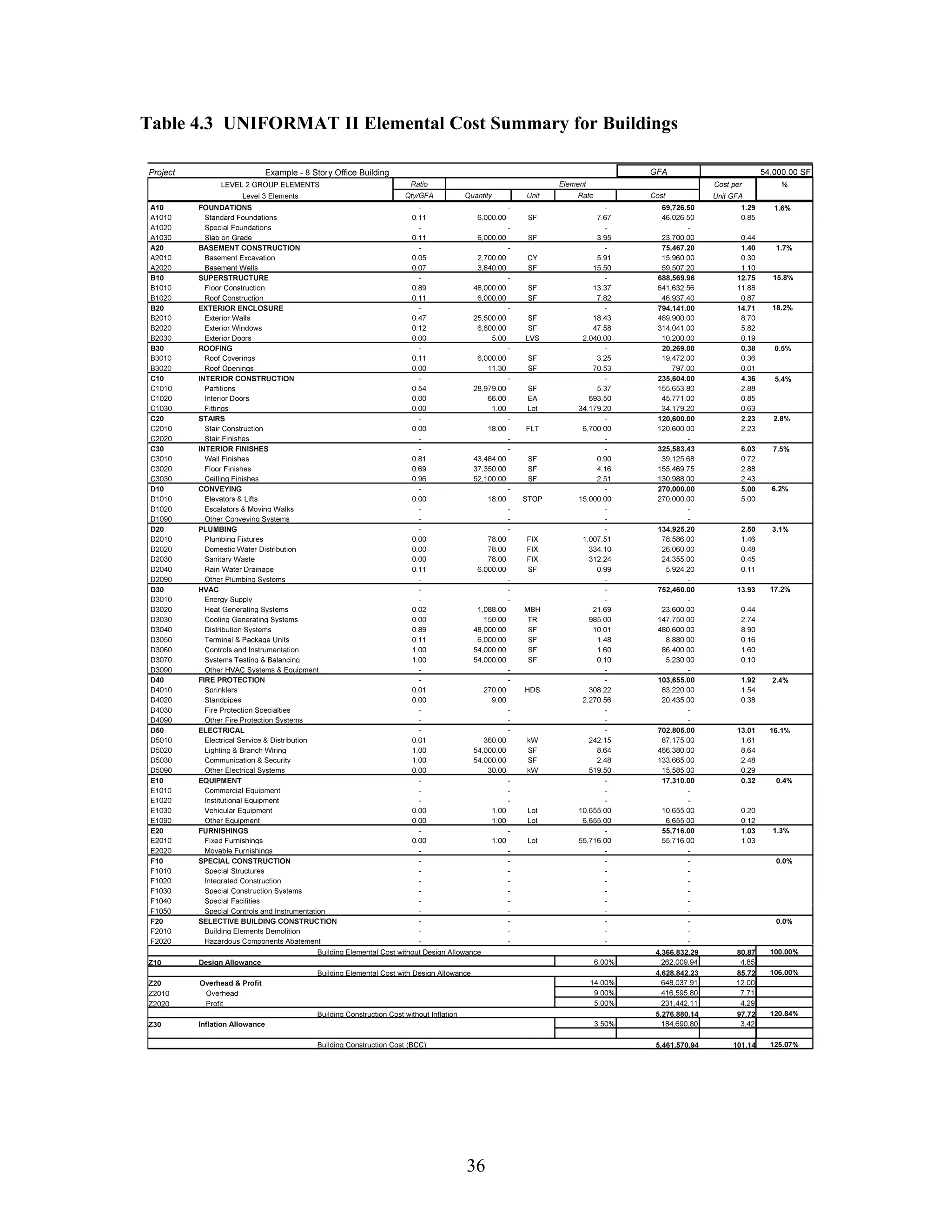

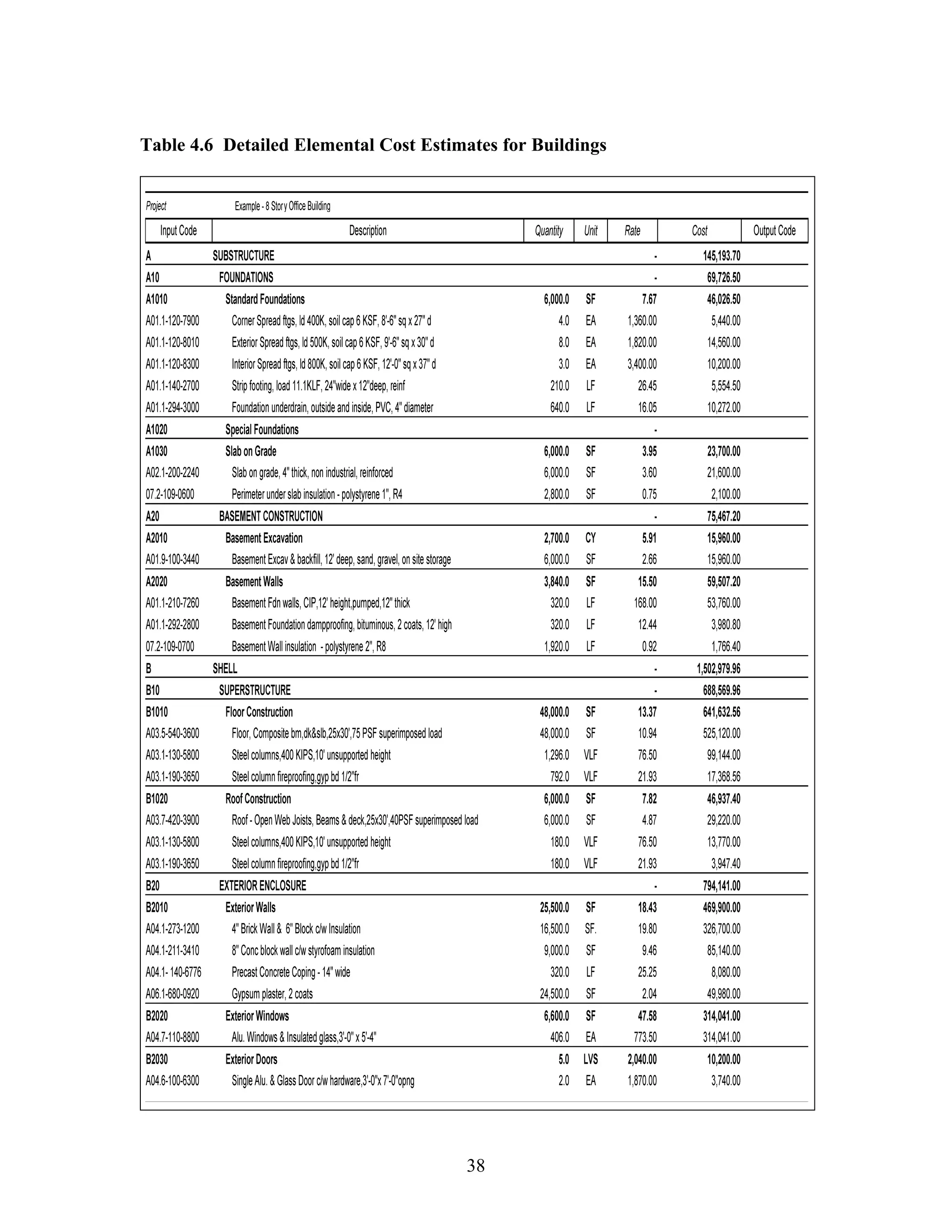

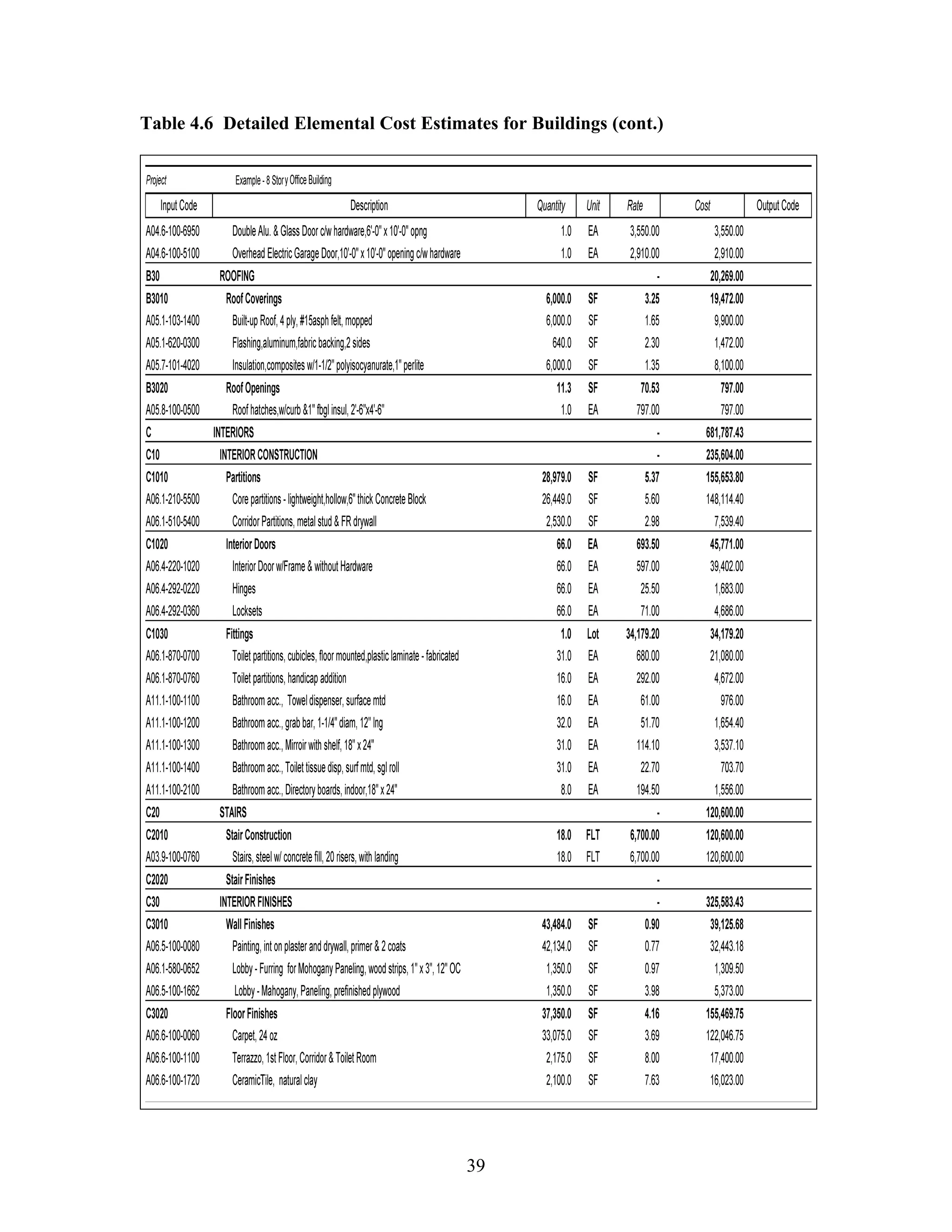

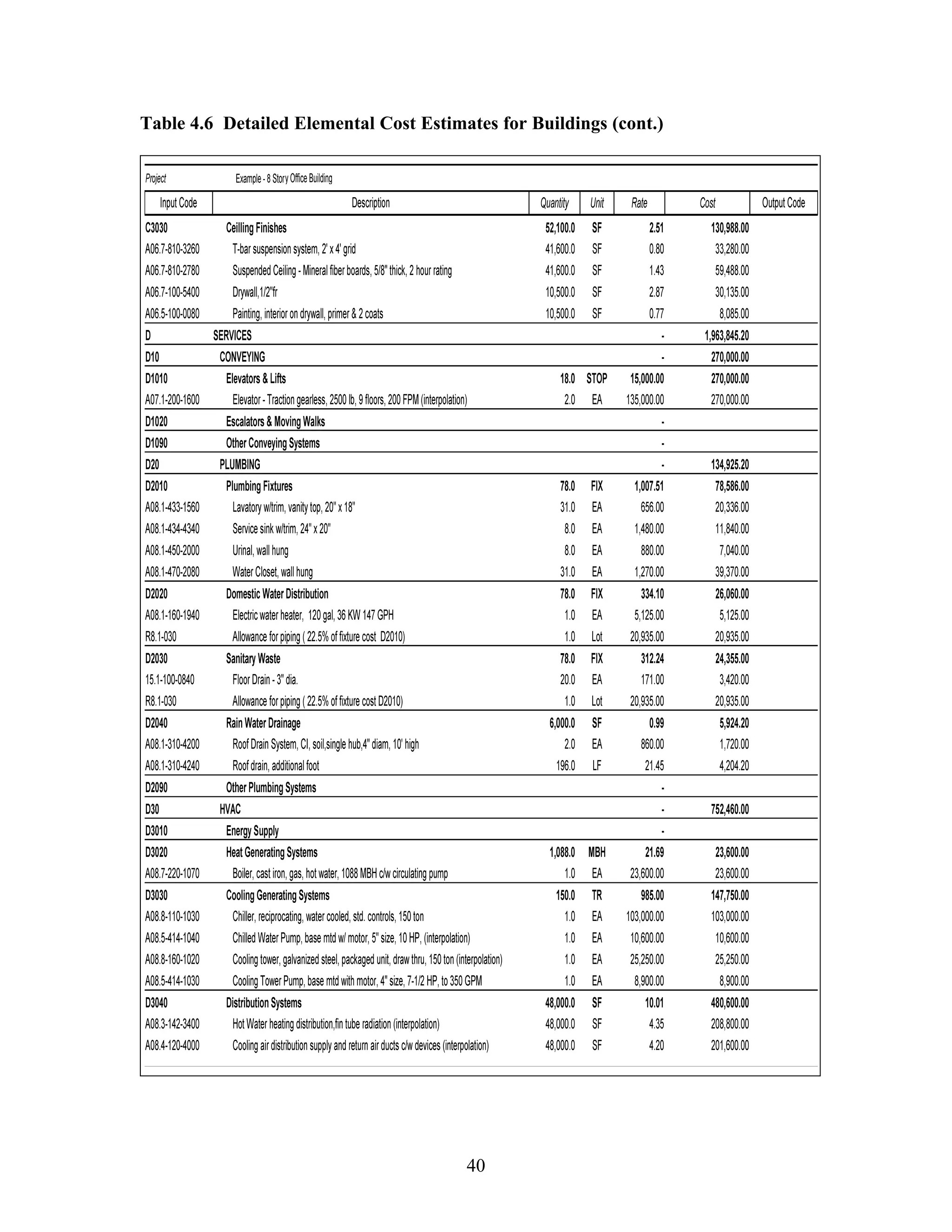

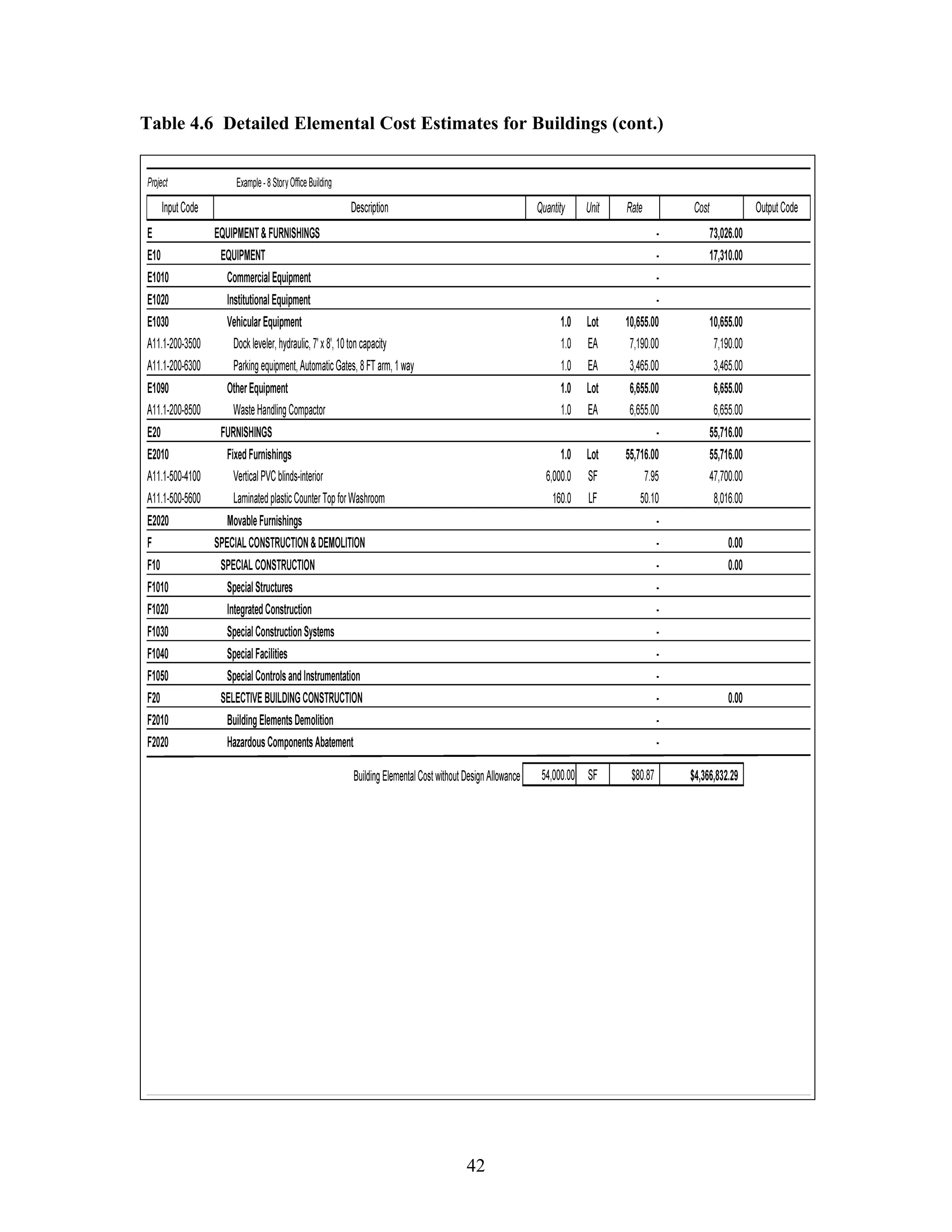

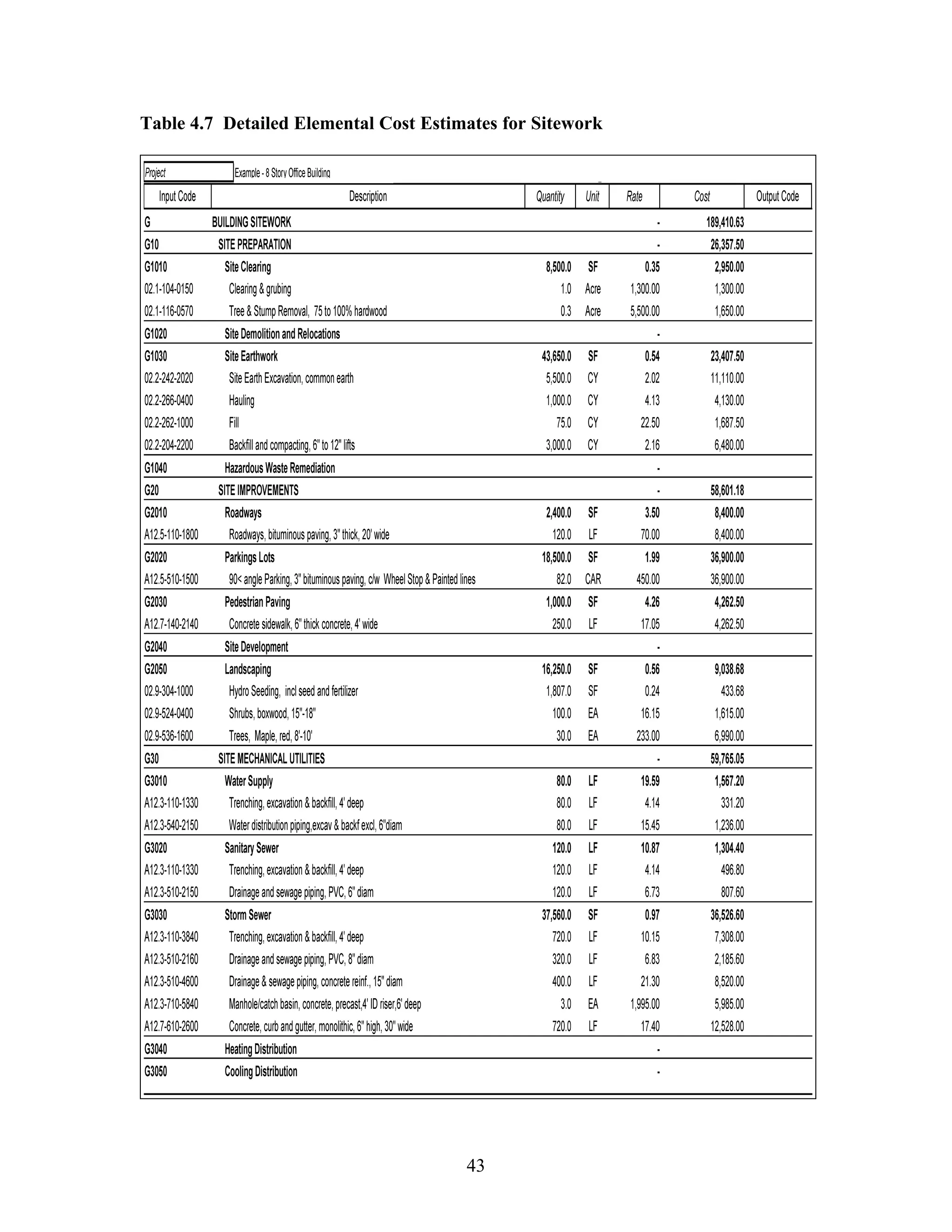

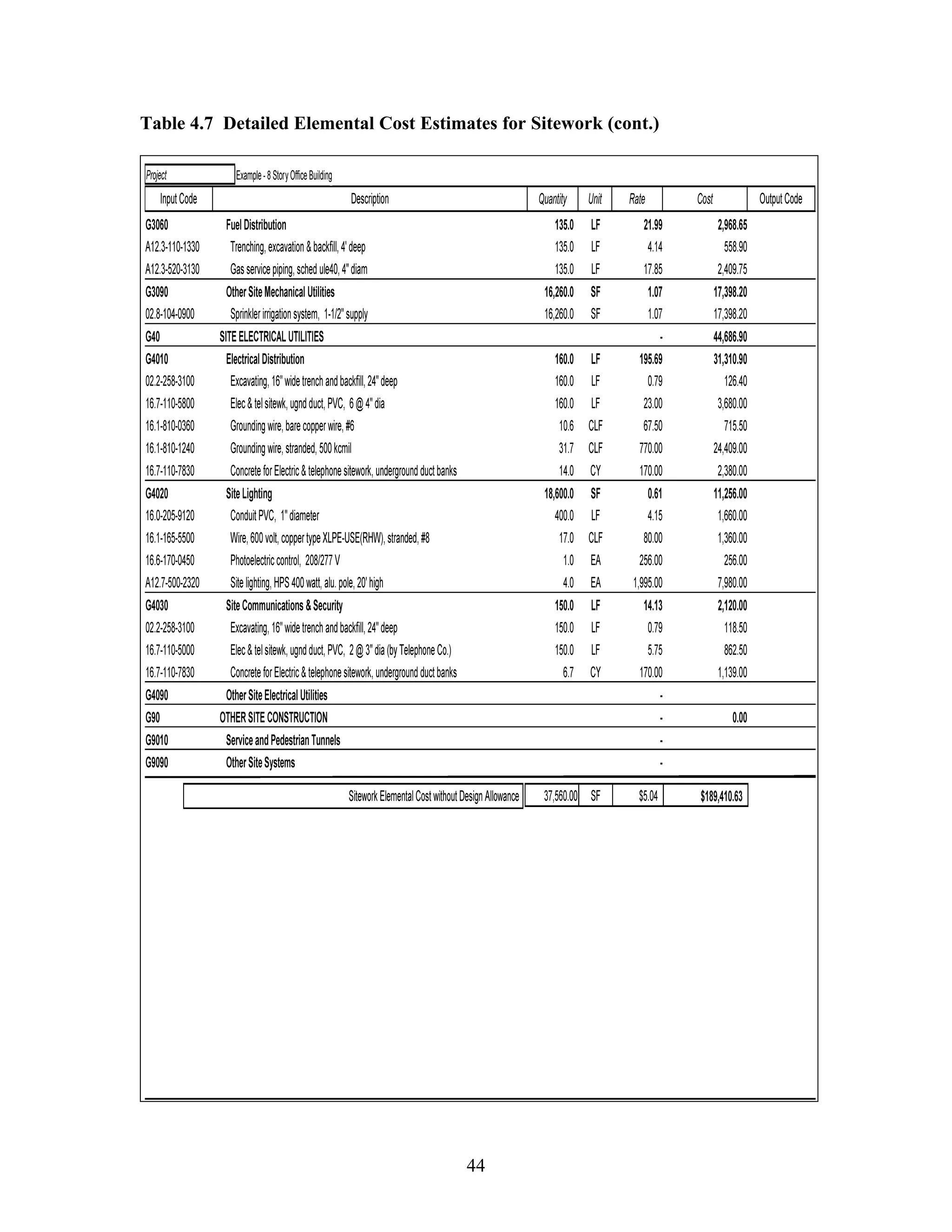

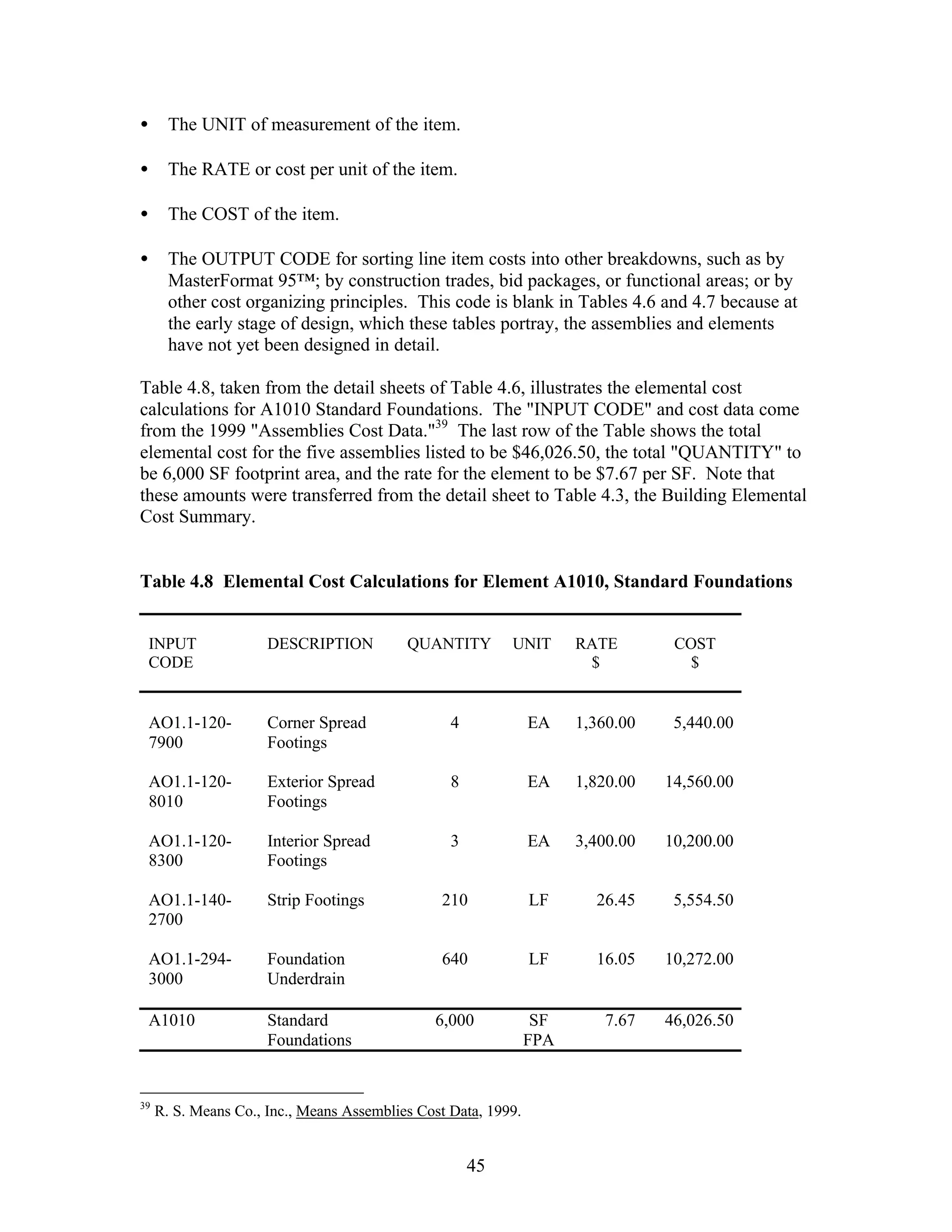

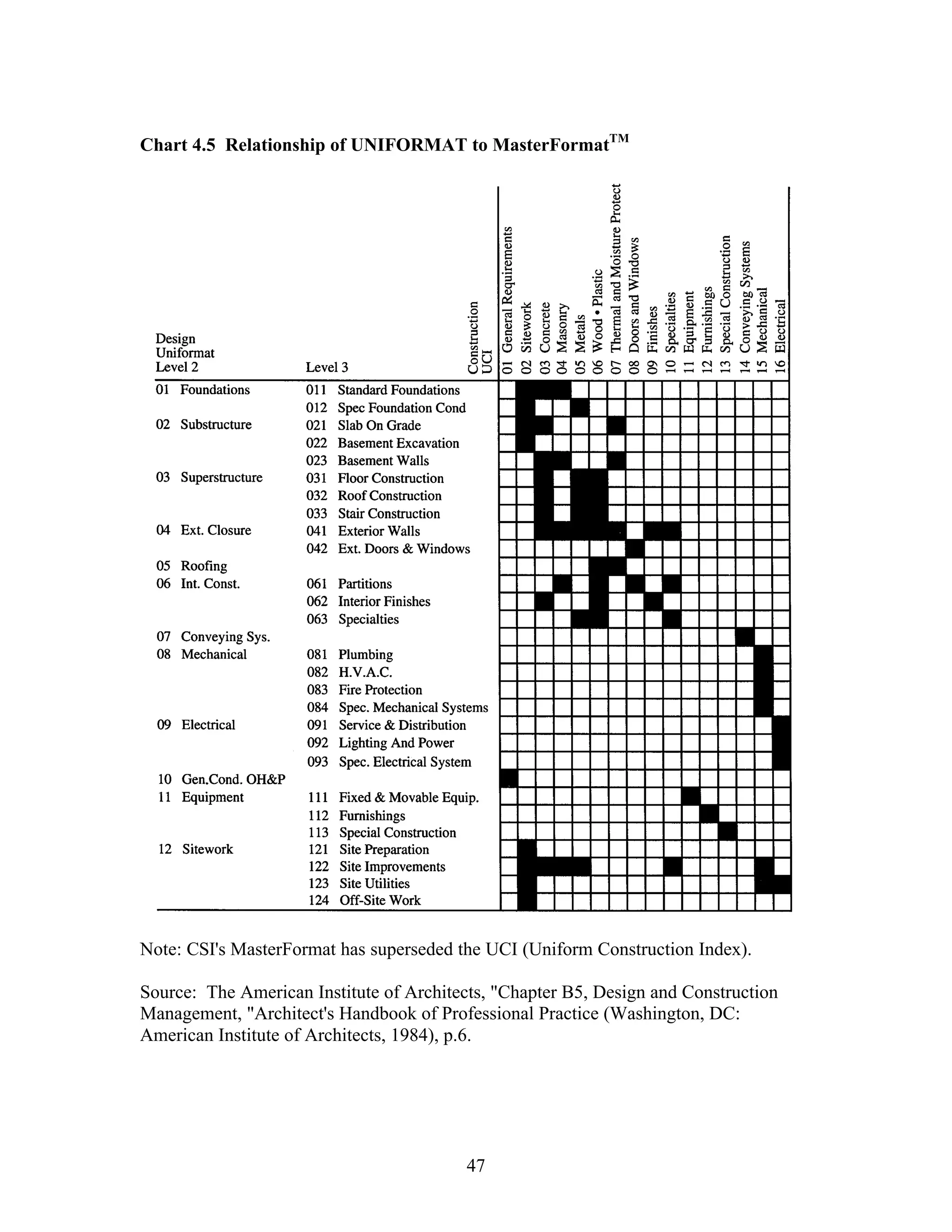

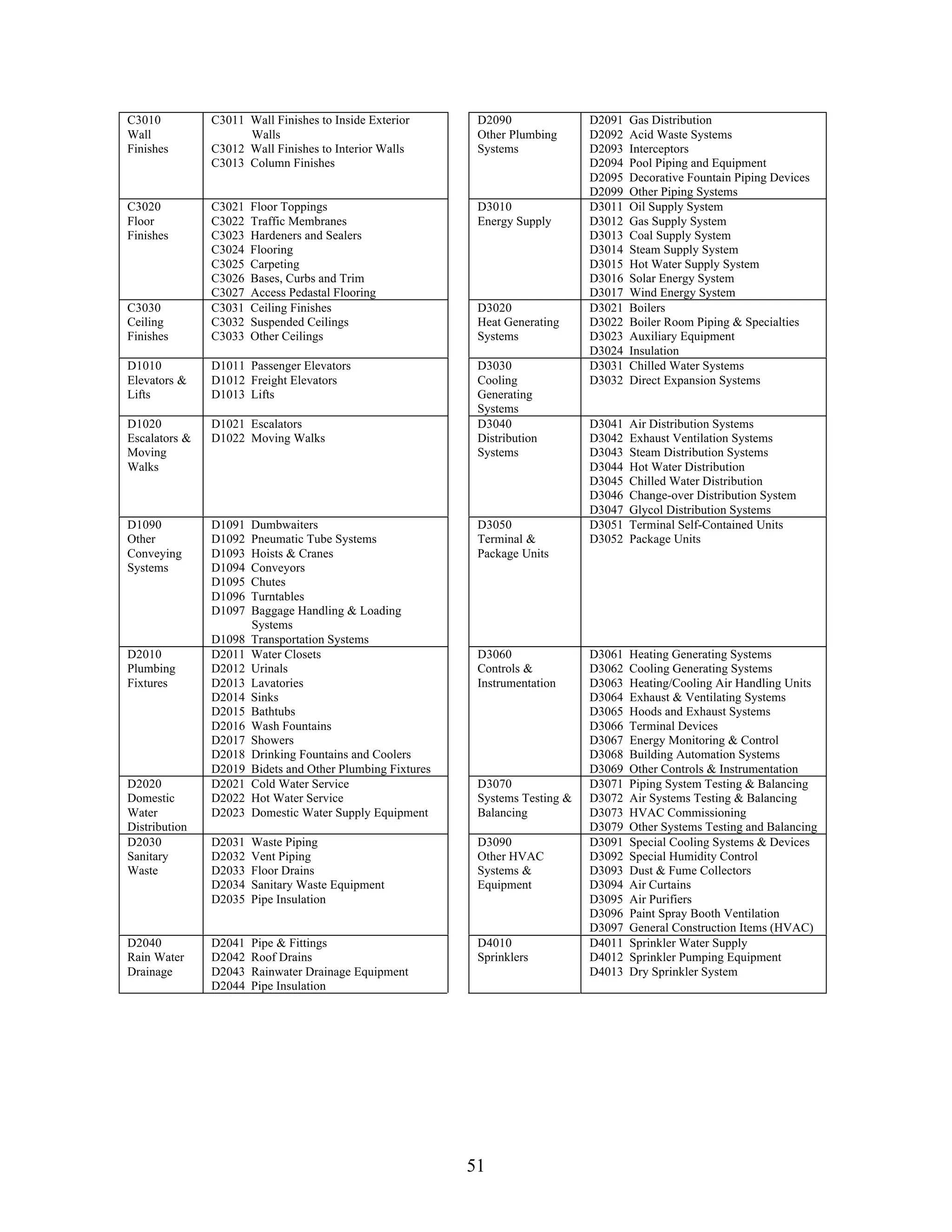

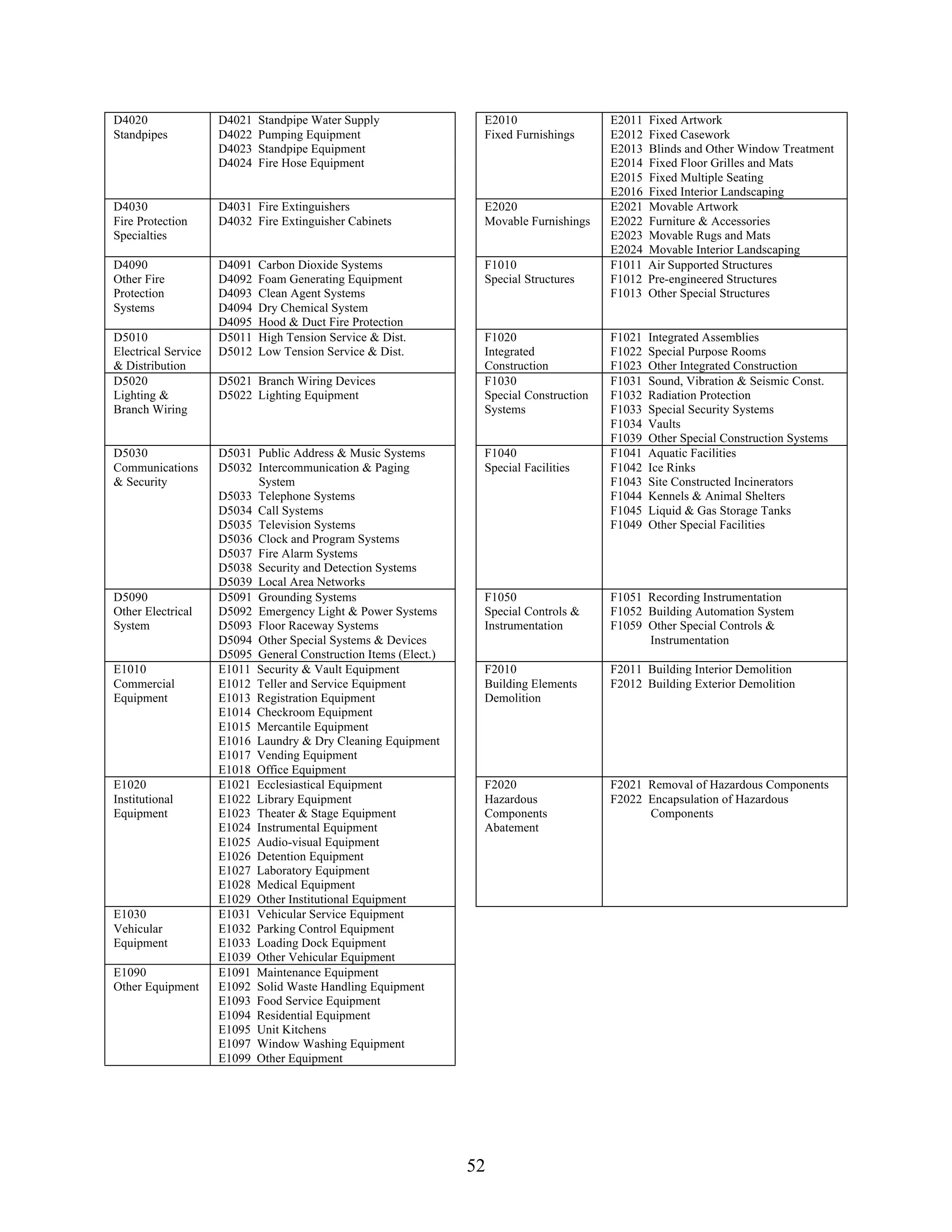

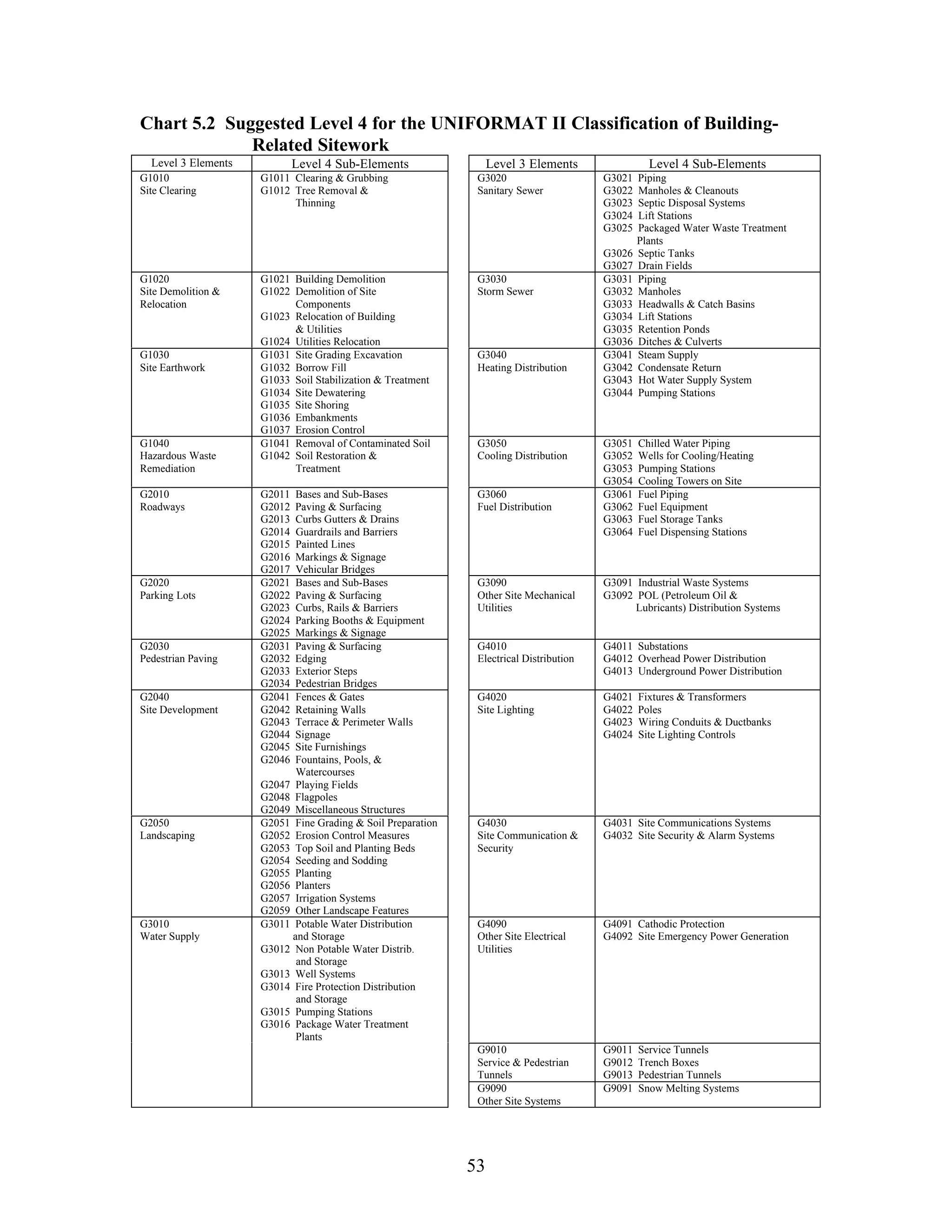

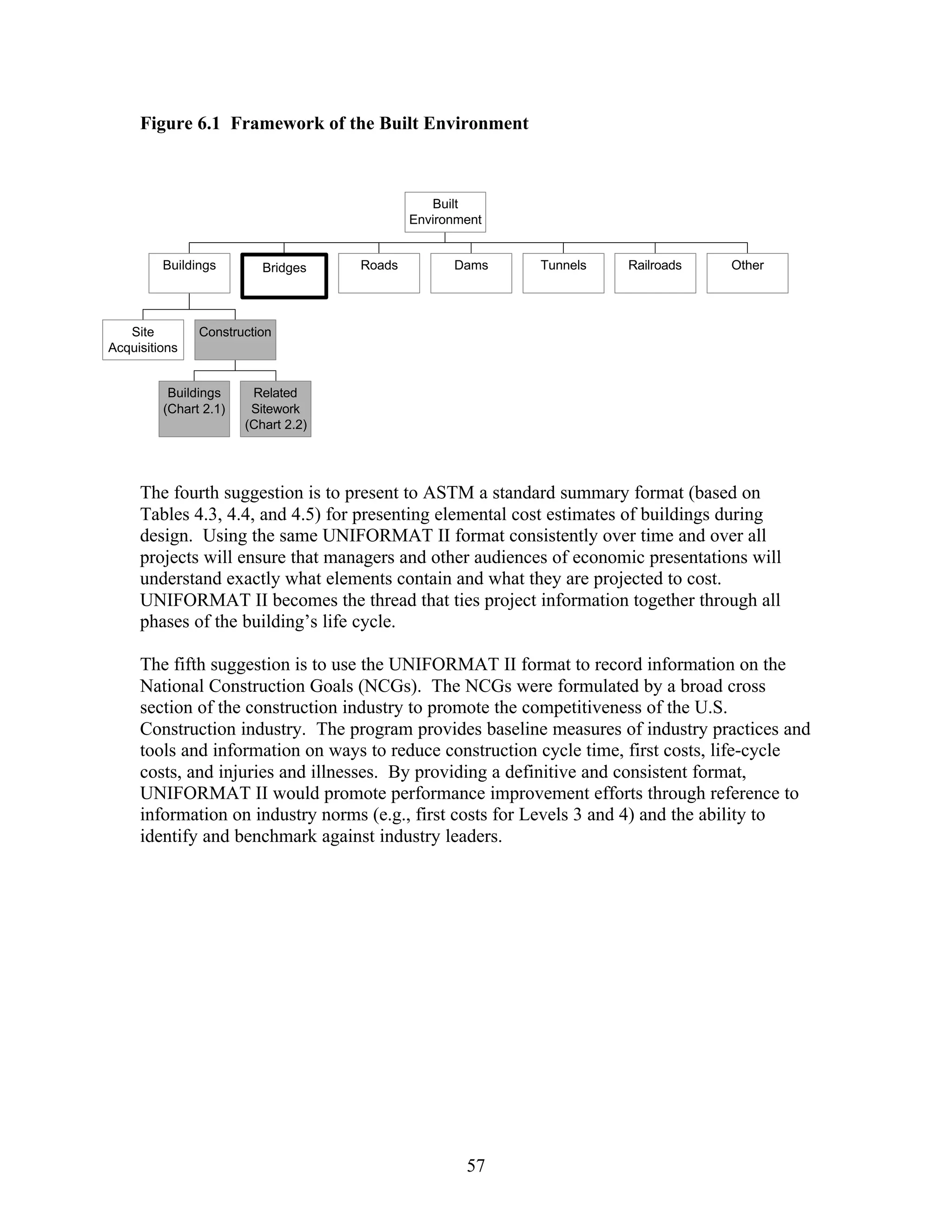

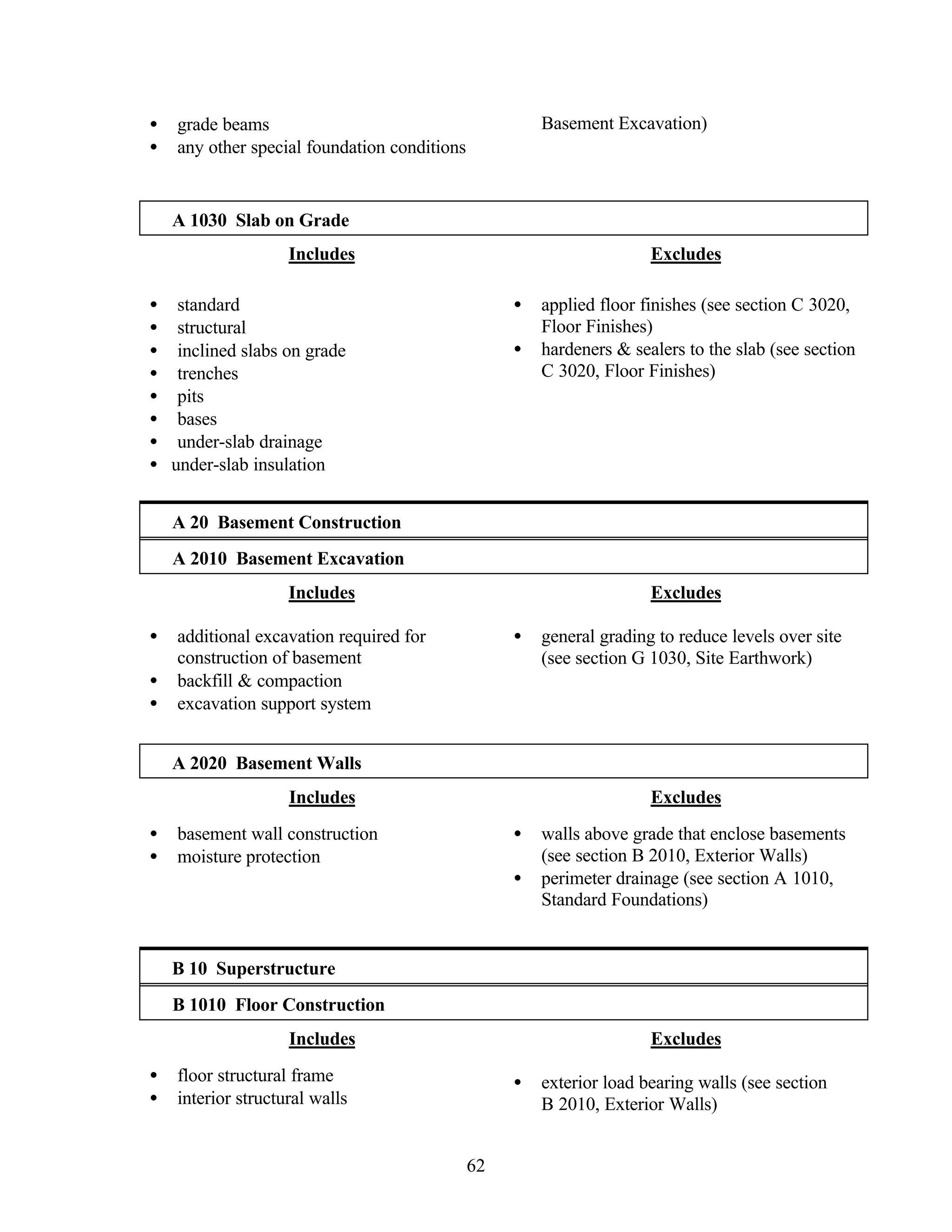

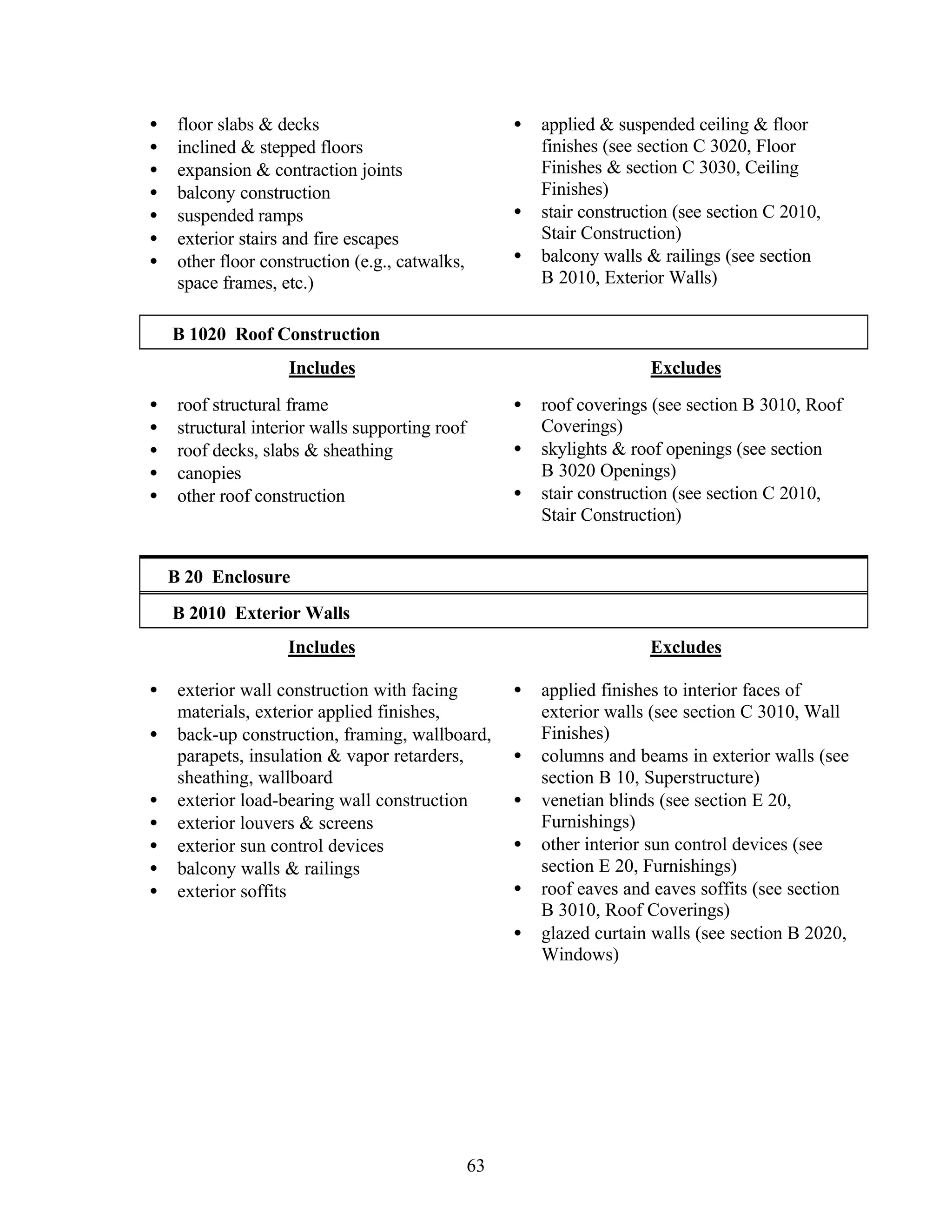

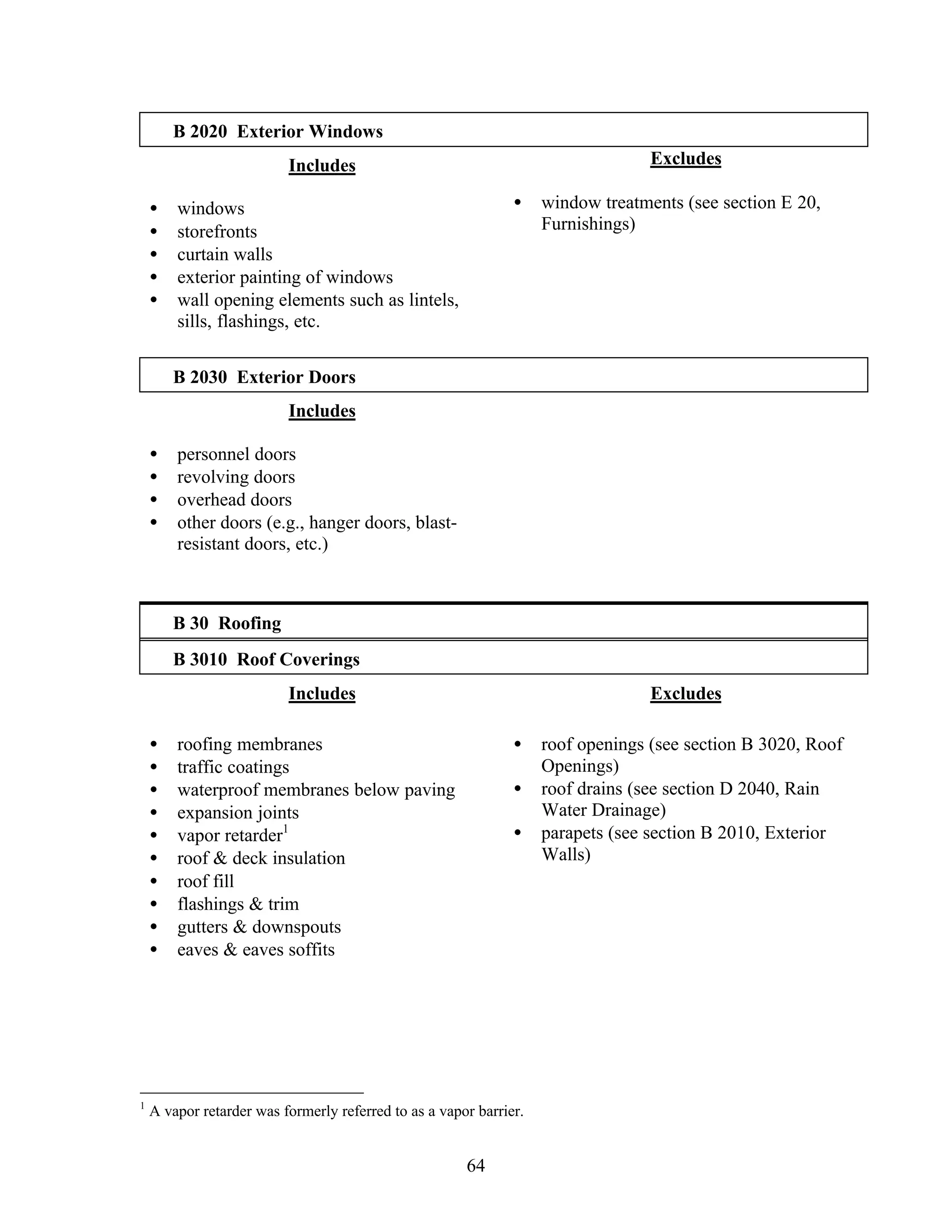

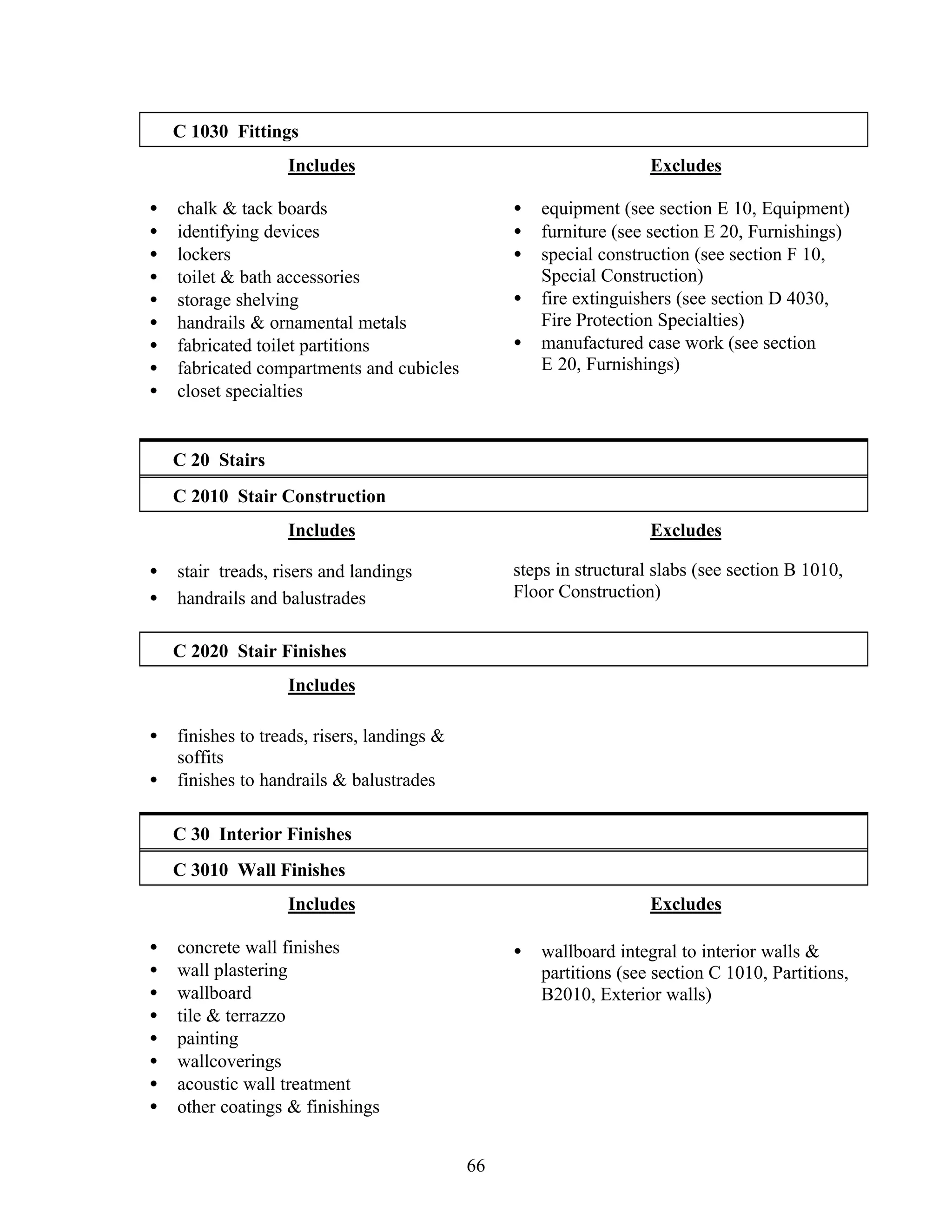

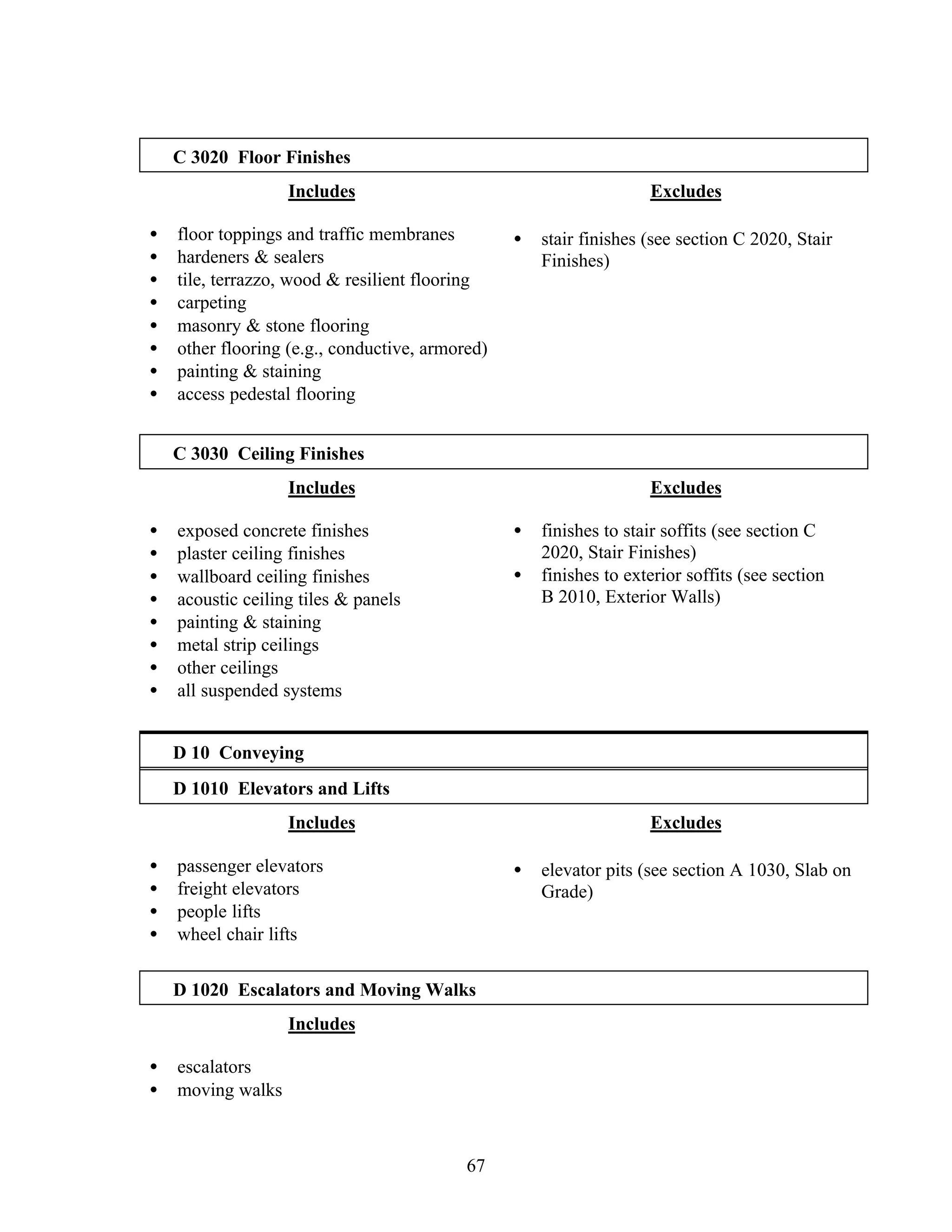

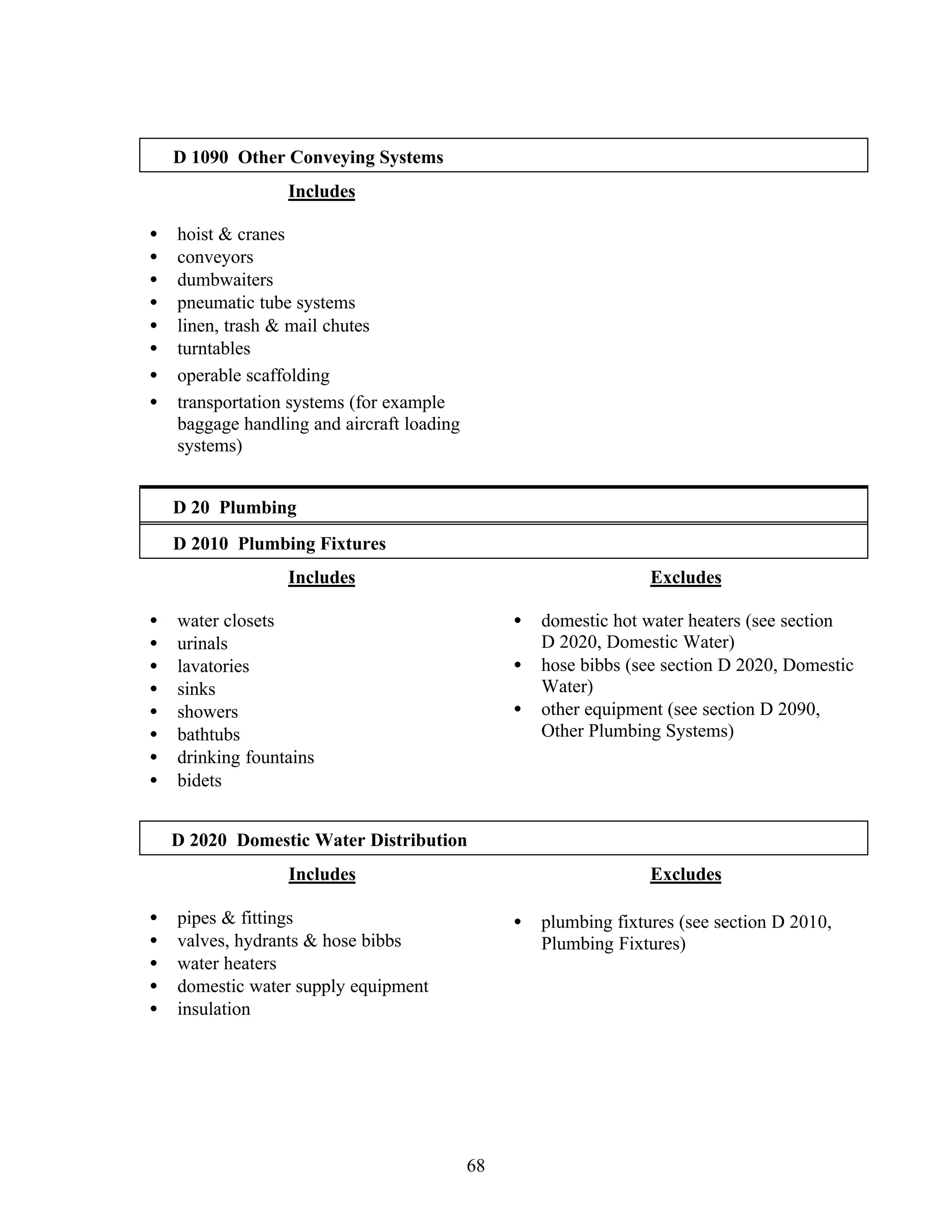

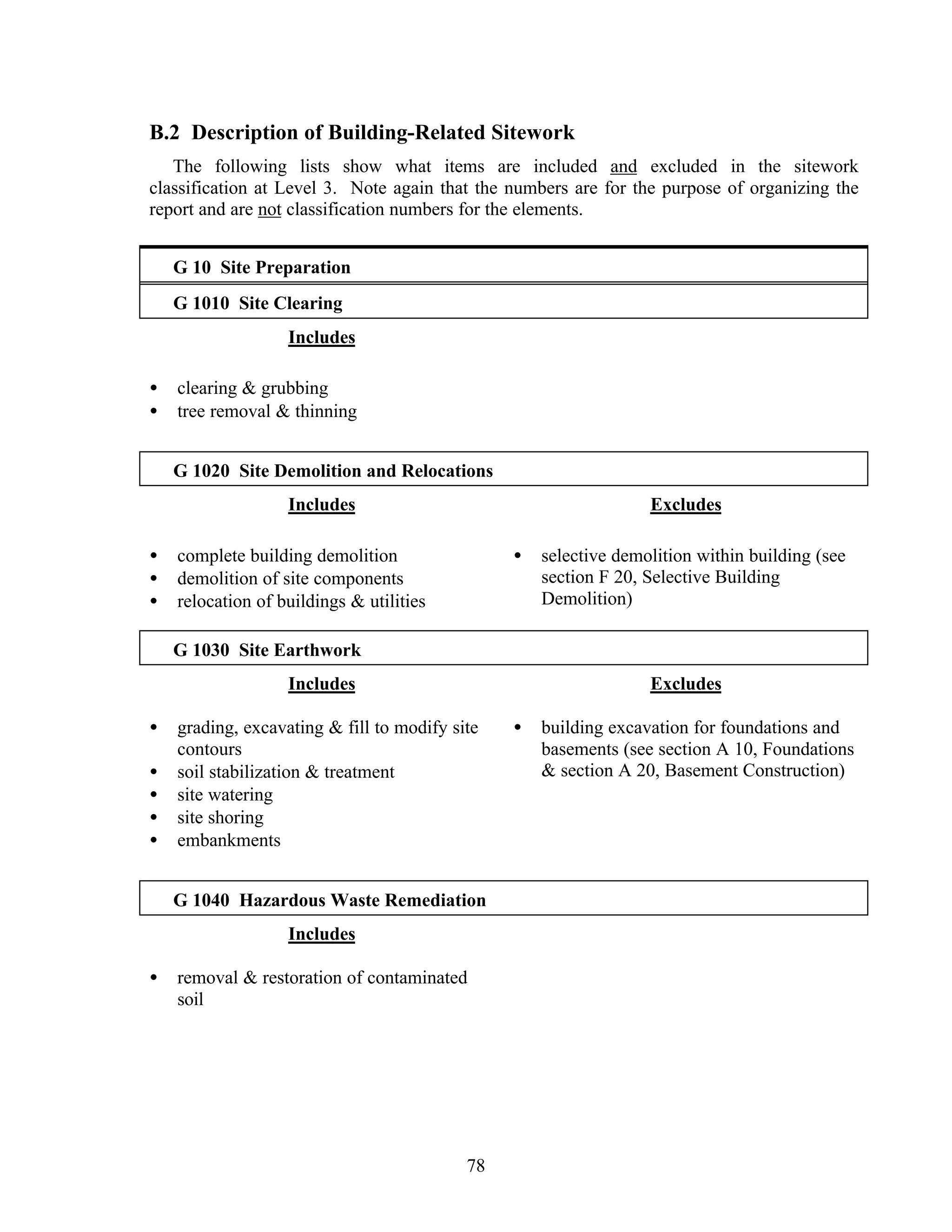

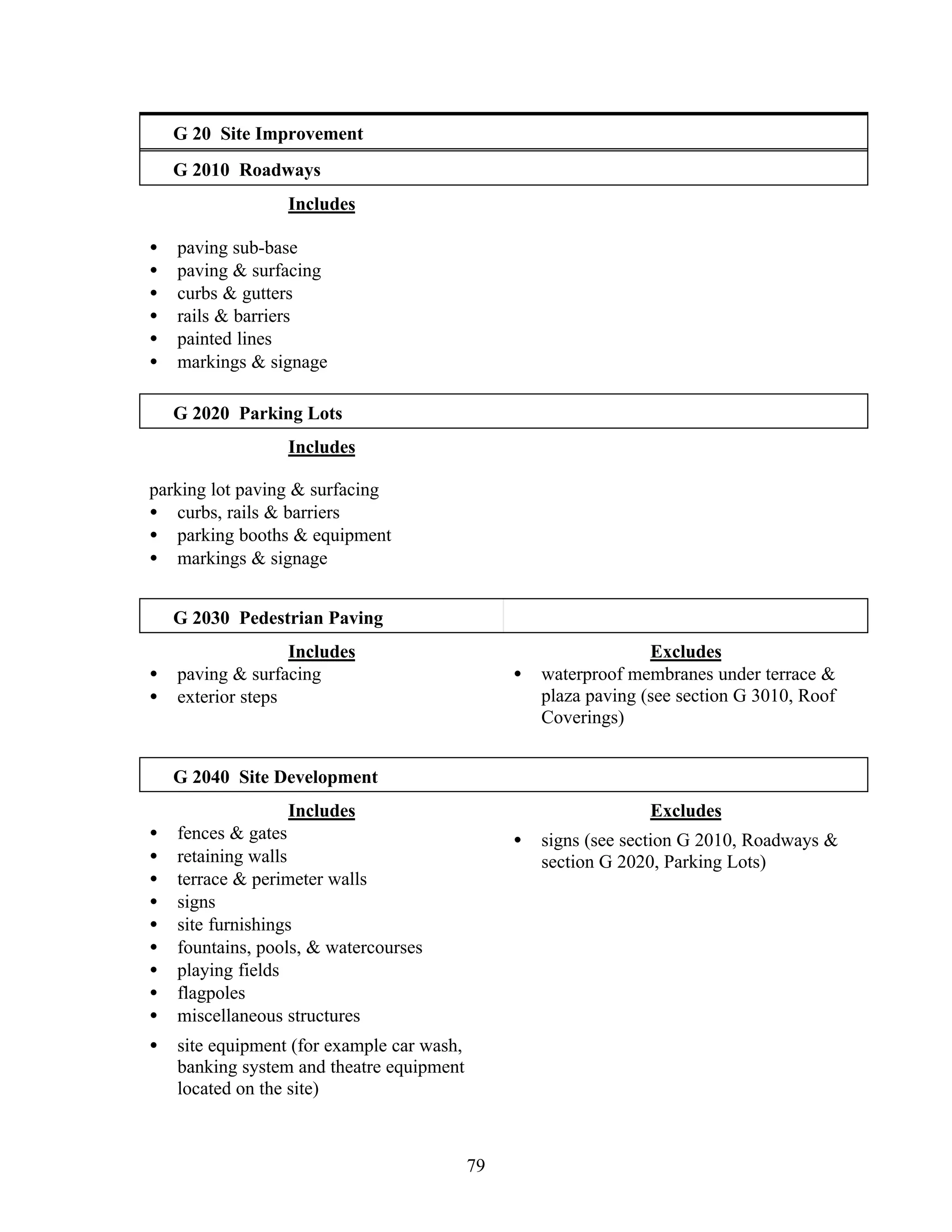

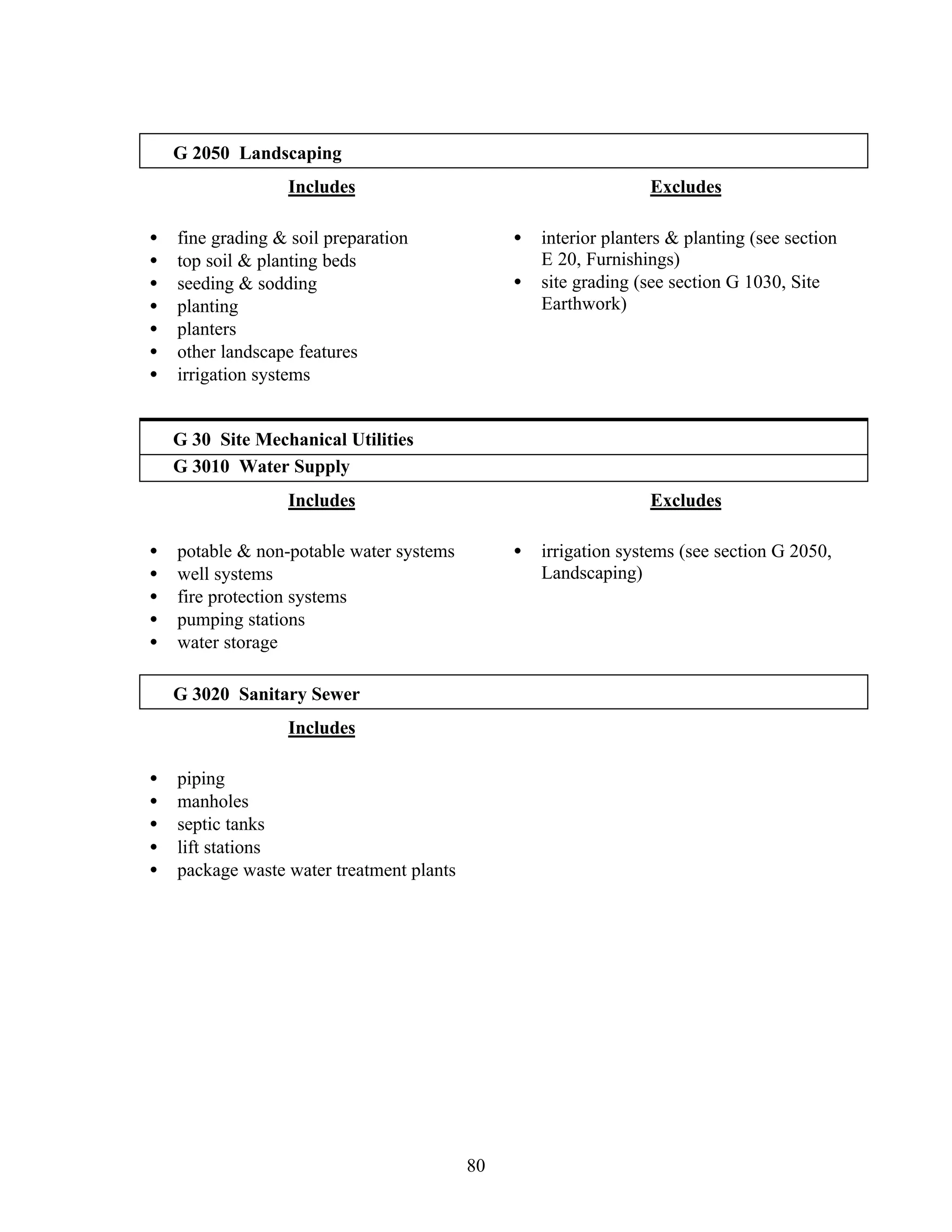

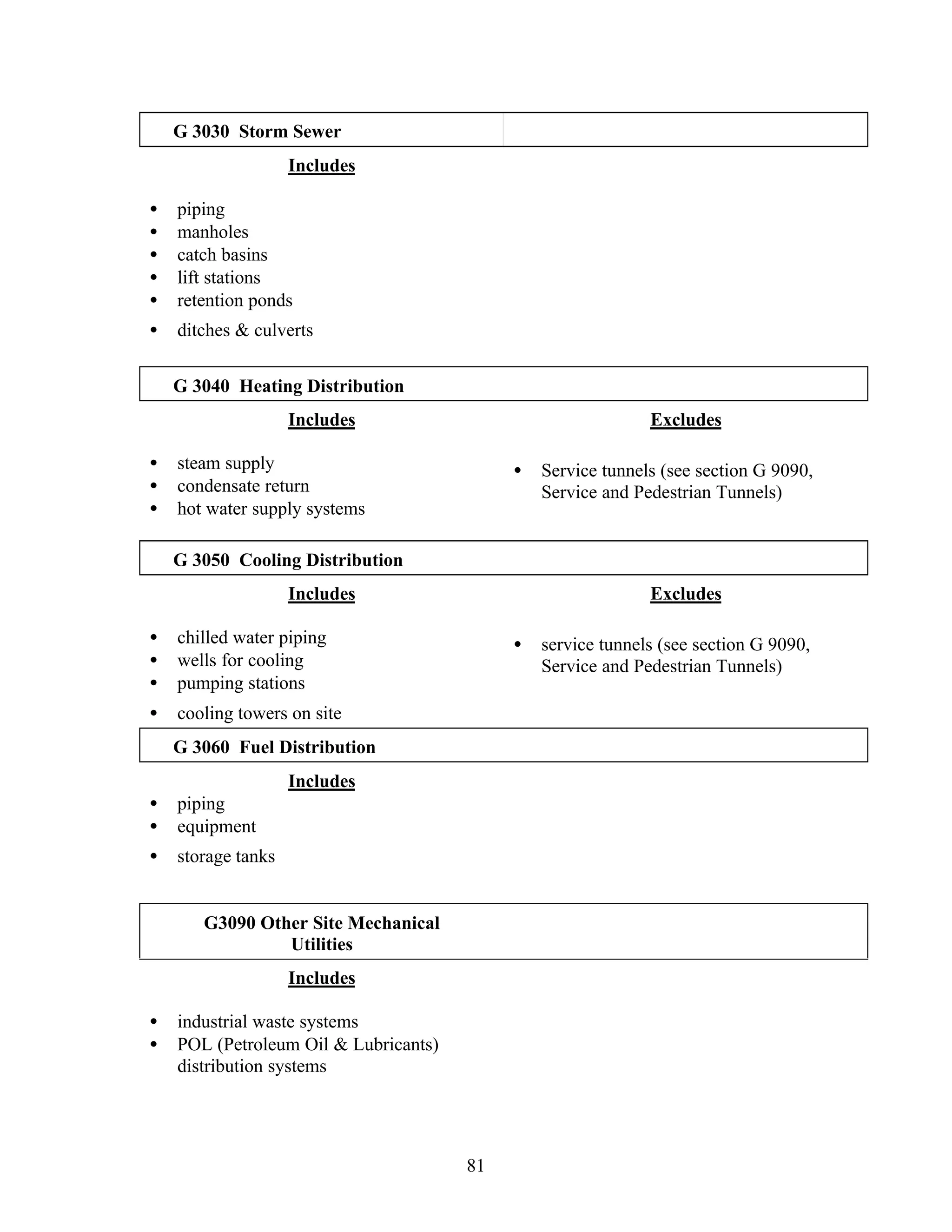

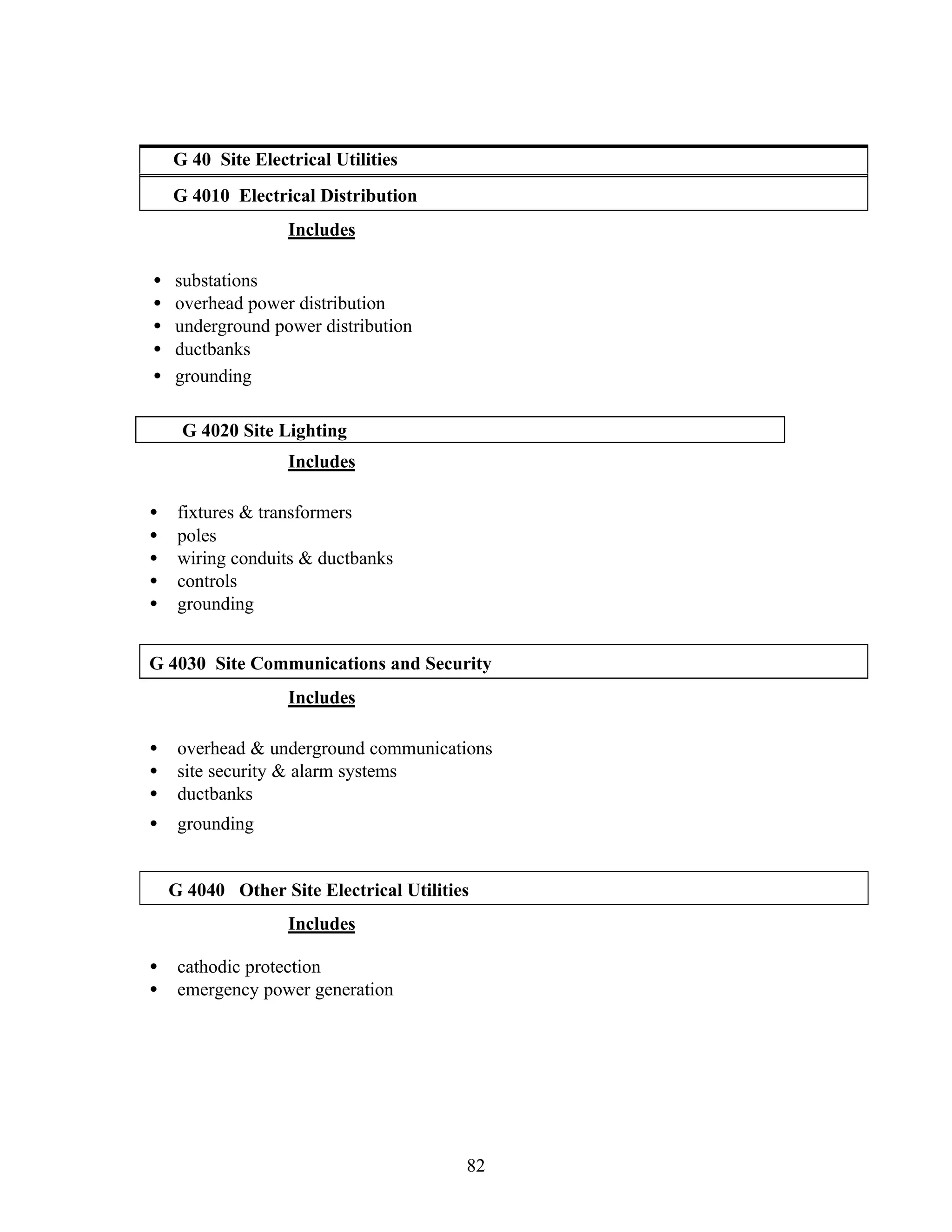

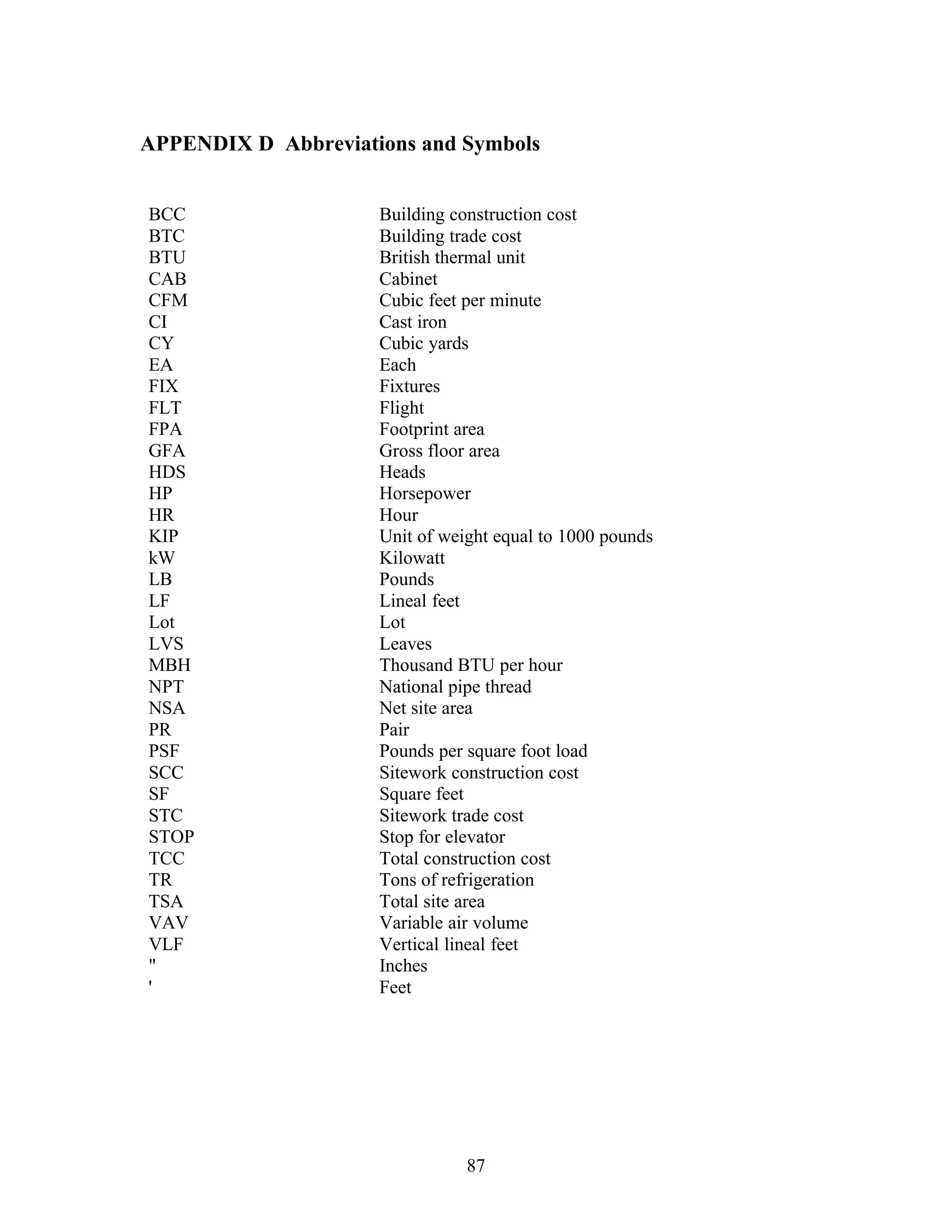

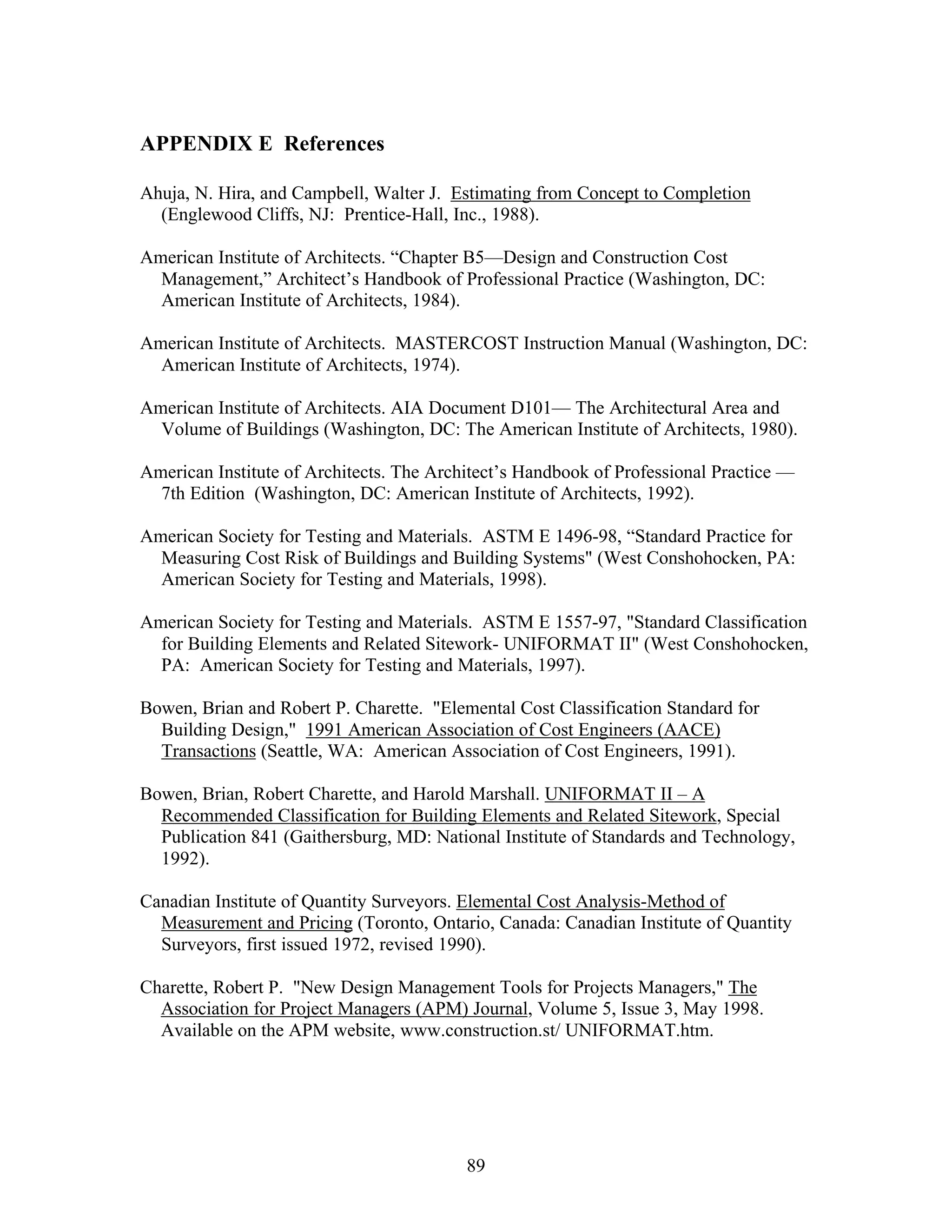

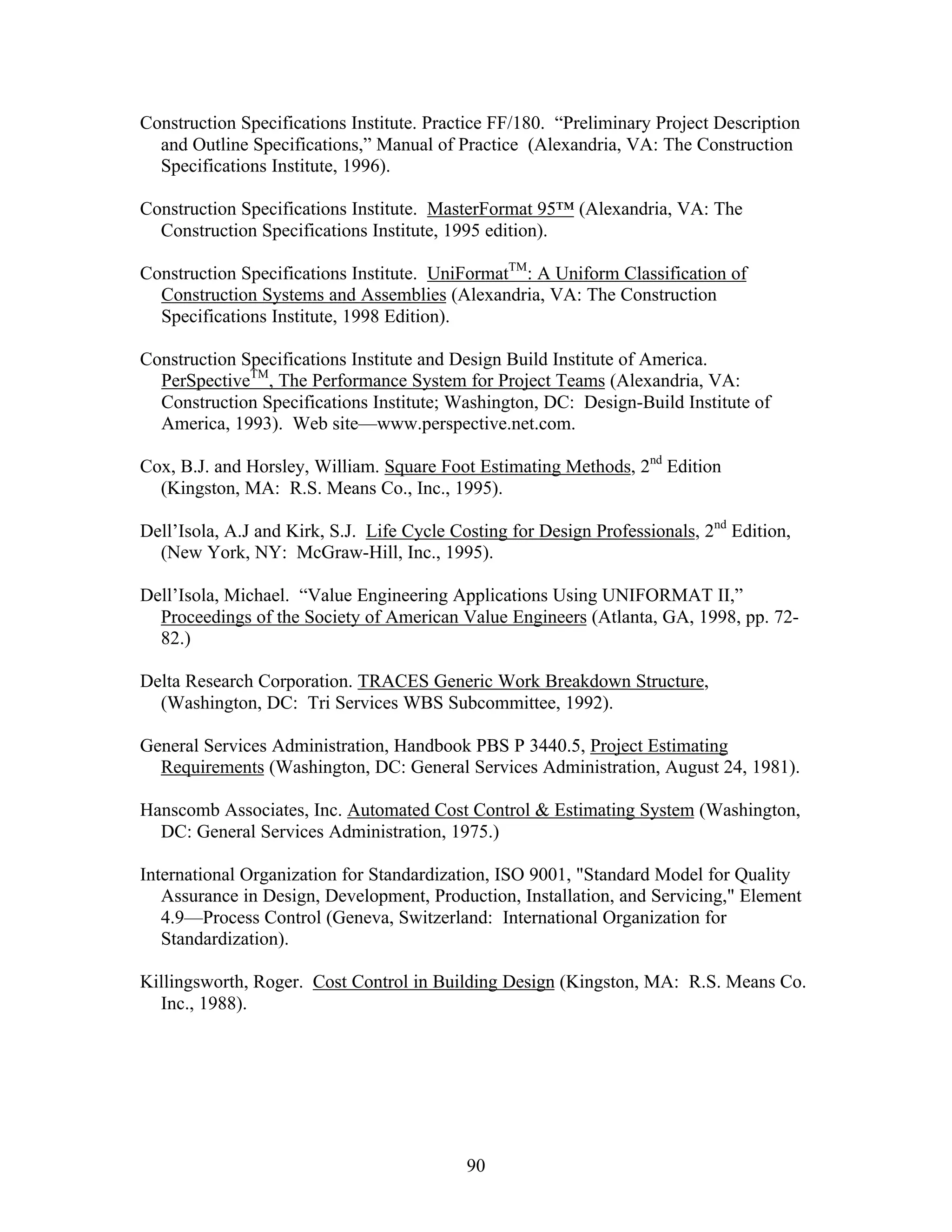

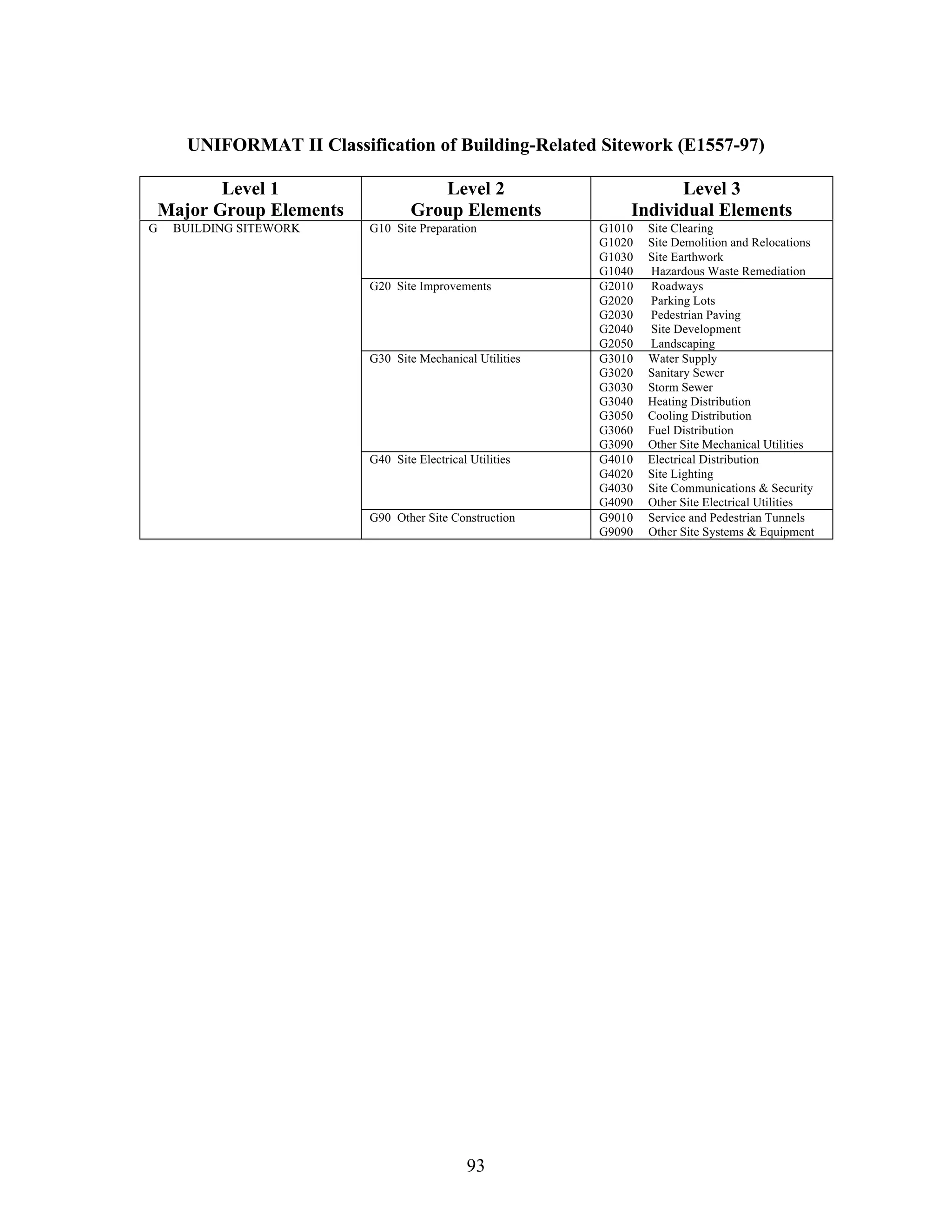

This document describes UNIFORMAT II, a standardized classification system for building elements used for specifications, cost estimating, and cost analysis. UNIFORMAT II classifies elements into four hierarchical levels, with Level 1 being the broadest groups (e.g. substructure, shell, interiors) and Level 4 being the narrowest sub-elements. The report proposes adding a fourth level of definition to UNIFORMAT II and provides a sample cost summary format to help present economic information concisely. UNIFORMAT II aims to bring consistency to economic evaluations over time and projects, helping decision makers evaluate building alternatives and choose efficient options.