Here’s a comprehensive overview of Resource Recovery in the context of Solid Waste Management (SWM), integrating types, methods, benefits, challenges, and real-world examples—supported by the latest web‑based sources.

1. What Is Resource Recovery? 🛠️

Resource recovery refers to the systematic diversion of waste intended for disposal into valuable materials or energy, keeping it in use as long as possible in compliance with circular economy principles

Climate → Sustainability Directory

+9

Encyclopedia.com

+9

grasshopper.net.au

+9

.

The EPA’s waste hierarchy places it just below reduce and reuse, ranking recycle and energy recovery above disposal

Encyclopedia.com

Wikipedia

.

2. Major Types of Resource Recovery

• Material Recovery

Recycling procedures that reclaim paper, plastic, metal, glass, textiles via sorting, cleaning, and processing into new materials

Climate → Sustainability Directory

Wikipedia

Eco Recycling Today

.

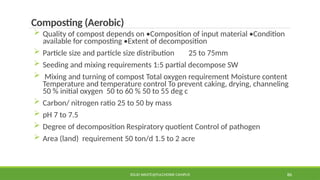

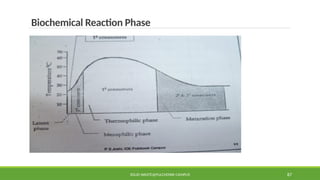

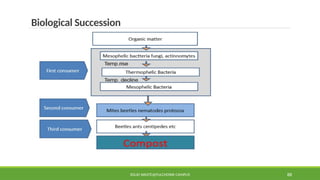

• Biological Recovery

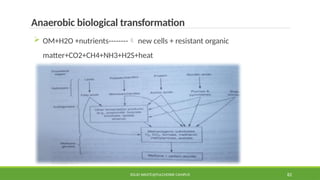

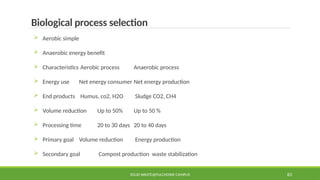

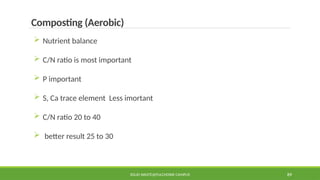

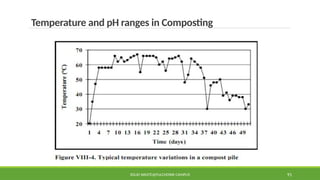

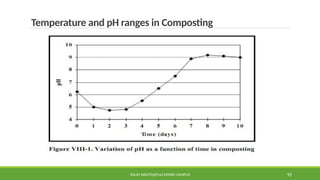

Processes that manage organic waste—composting and anaerobic digestion—producing compost or biogas and digestate (organic fertilizer)

Wikipedia

+7

Climate → Sustainability Directory

+7

Omics Online Publishing

+7

.

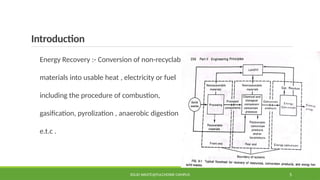

• Energy Recovery

Also called waste-to-energy (WtE): incineration, gasification, pyrolysis, or landfill gas capture to generate heat, electricity, or fuel from non-recyclable waste streams

Wikipedia

+2

Wikipedia

+2

Wikipedia

+2

.

• Chemical Recovery

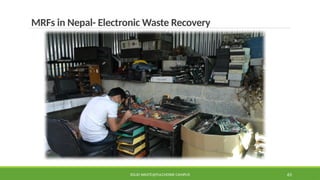

Specialized extraction of valuable chemicals or solvents—such as from e‑waste, industrial residues, or specialized plastics—that can be reused in manufacturing

Climate → Sustainability Directory

.

• Co-Processing

Industrial symbiosis where waste acts as alternative fuel or raw material in high-energy industries (e.g. cement kilns), reducing fossil fuel reliance and landfill load

REPSOL

+2

Wikipedia

+2

ScienceDirect

+2

.

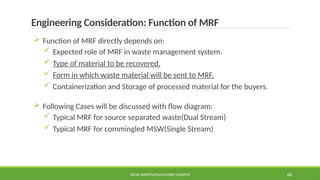

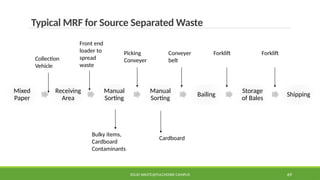

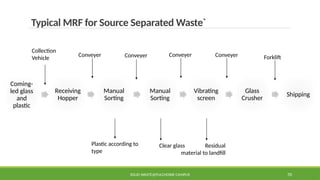

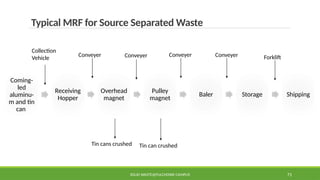

3. Methods & Techniques

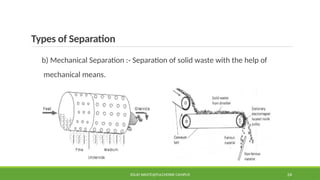

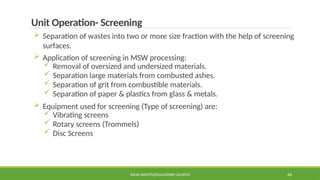

• Collection & Sorting

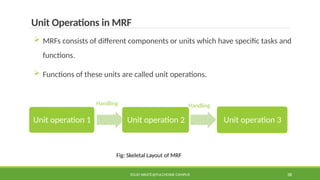

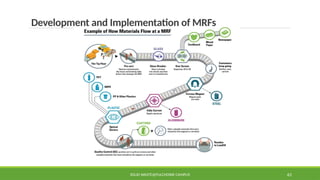

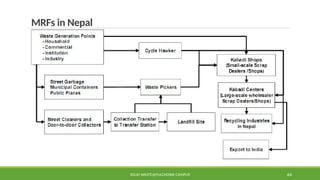

Source-separated collection (e.g. curbside bins for recyclables or organics) or centralized Material Recovery Facilities (MRFs) that mechanically and manually sort waste streams

Encyclopedia Britannica

Wikipedia

Eco Recycling Today

.

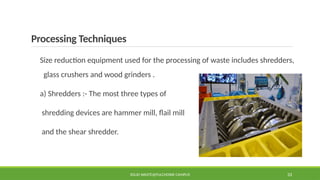

• Processing

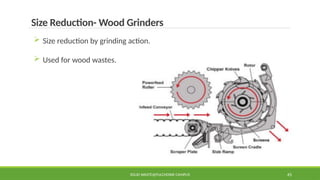

Mechanical recycling: shredding, melting, baling

Chemical recycling: depolymerization of plastics into feedstock

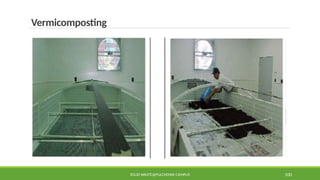

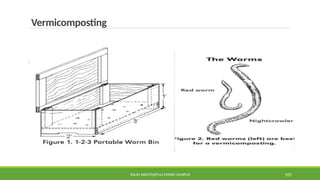

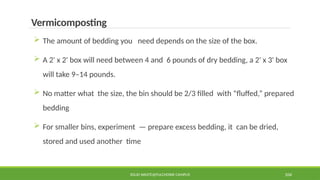

Composting and vermicomposting

Anaerobic digestion for biogas and digestate production

Omics Online Publishing

+1

Climate → Sustainability Directory

+1

Wikipedia

.

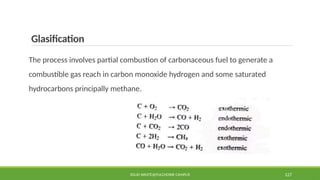

• Thermal & Chemical Conversion

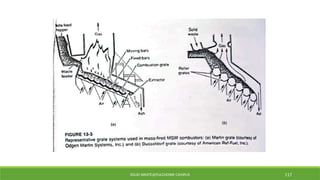

Incineration: controlled combustion with energy recovery (heat, electricity), typically reducing volume by up to 90%

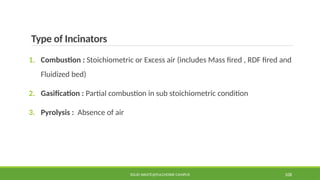

Wikipedia

.

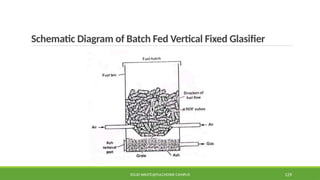

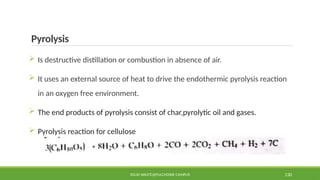

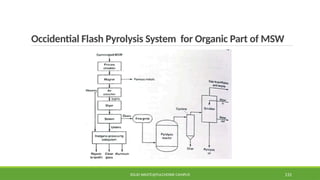

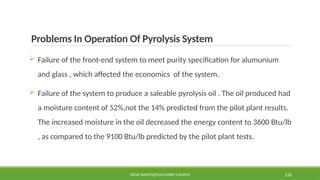

Gasification, pyrolysis, plasma arc gasification: thermo-chemical processes producing syngas, bio-oil, char, synthetic fuels with lower emissions

Wikipedia

+1

Wikipedia

+1

.

• Biomining & Bioremediation

Recovering and processing legacy waste (e.g. old landfill sites) via excavation and microbial treatments to reclaim materials and process residues

The Times of India

Encyclopedia.com

.

4. Bene