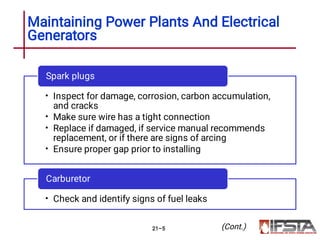

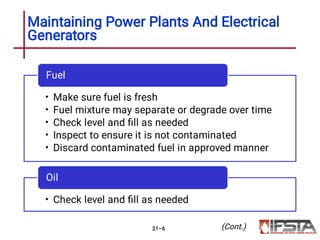

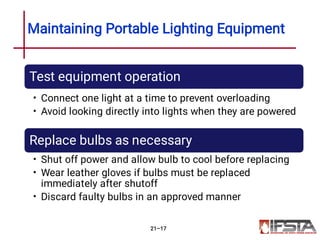

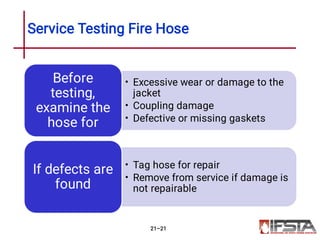

This document discusses procedures for maintaining firefighting equipment, including generators, rescue tools, lighting equipment, and fire hose. It provides guidance on inspecting and testing this equipment according to manufacturers' recommendations to ensure it is fully operational. When maintaining generators, key items to check include electrical connections, spark plugs, fuel levels and quality, oil levels, and performing startup tests. For rescue tools, the document outlines inspecting parts and accessories, charging batteries and air cylinders, checking fluid levels, and ensuring guards are installed. Service testing fire hose annually and after repairs includes examining the hose for defects, pressurizing sections up to 300 feet, and recording test results, repairs, and hose dispositions. Personnel should