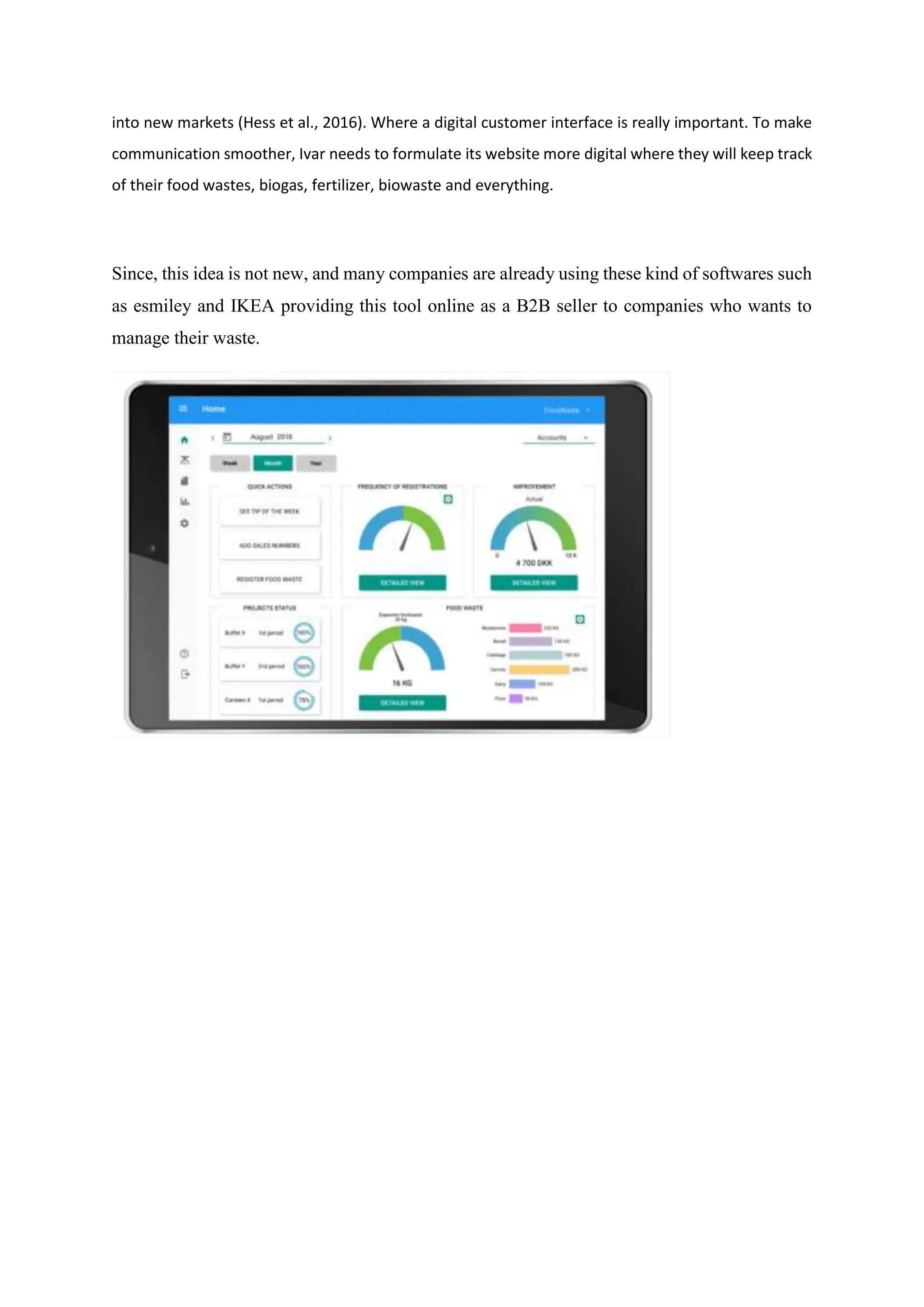

The document is a project report by a group focused on digitalization and sustainability at IVAR IKS, a waste management company in Norway. It outlines their engagement, investigation, and acting phases in addressing food waste through digital solutions, highlighting challenges faced in data collection and the need for improved digital tools. Recommendations include implementing an ERP software system to enhance efficiency and better manage food waste processes.