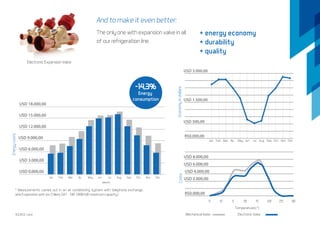

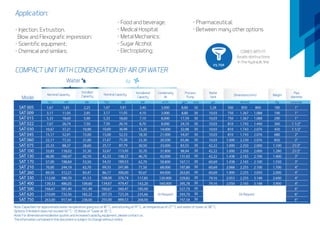

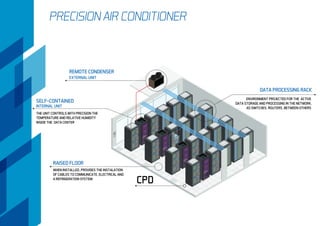

REFRISAT is a Portuguese company founded in 1976 that specializes in thermal control equipment and technologies. It has sold over 15,000 equipments in Latin America and is a leader in various sectors including food, medical, metalworking, and data centers. The company prides itself on quality, technological innovation, and being the first to invest in automation, digital resources, and an internal laboratory for product development.