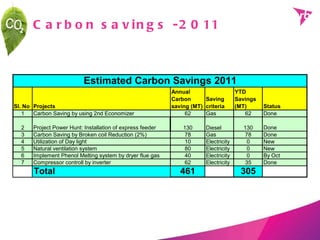

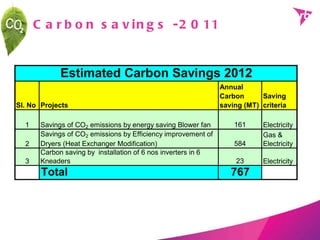

This document summarizes the estimated carbon savings from various projects implemented by an industrial supply chain in Chittagong, Bangladesh in 2011 and 2012. In 2011, the total estimated annual carbon savings were 461 metric tons from 7 projects, with 305 metric tons saved year-to-date. In 2012, the total estimated annual carbon savings from 3 projects were projected to be 767 metric tons.