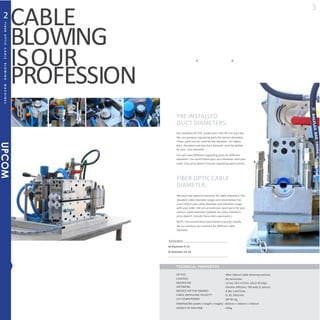

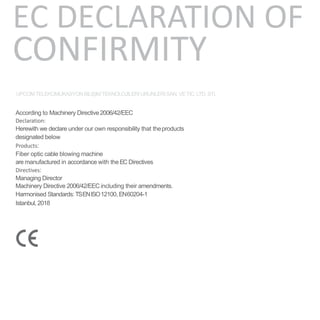

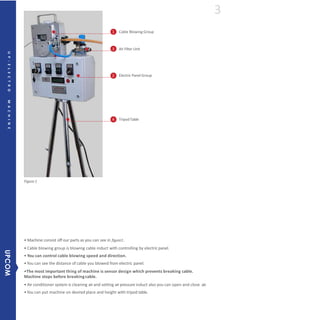

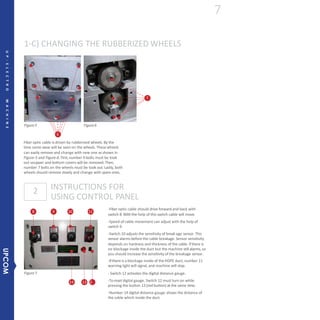

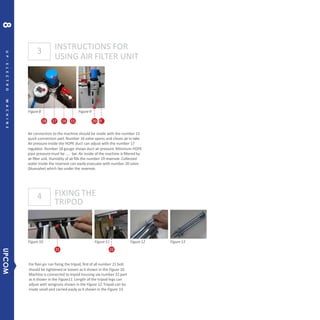

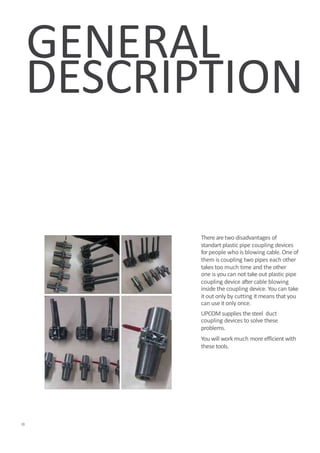

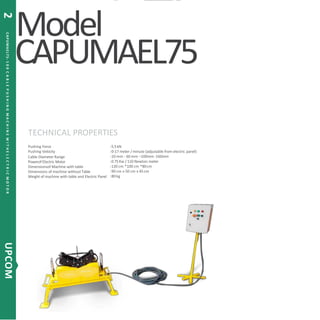

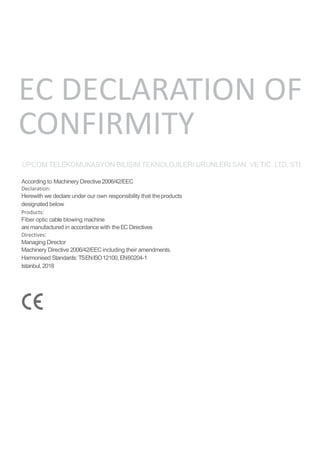

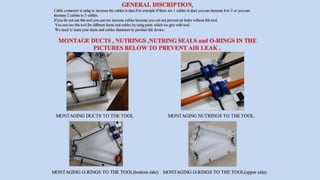

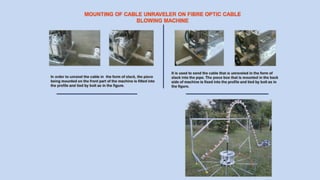

This document provides information about a fiber optic cable blowing machine called the UP-HYDRO, including its quality policy, vision, mission, and technical details. The UP-HYDRO is a hydraulic cable and tube blowing machine that is designed to blow cable and tubes through ducts. It includes a hydraulic power unit to provide hydraulic power. The company aims to provide high quality products and services, maximize customer satisfaction, and create value for employees and customers.