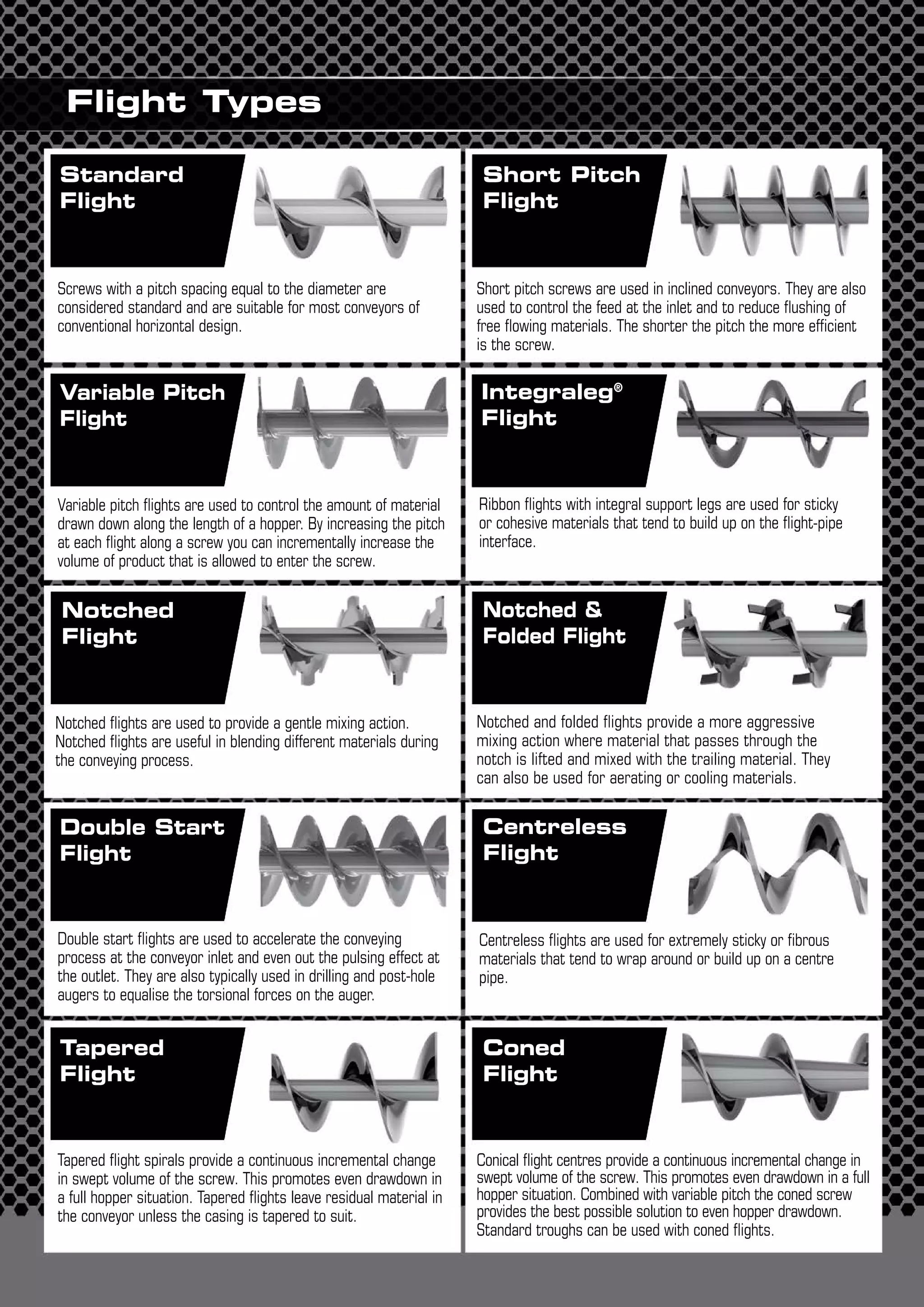

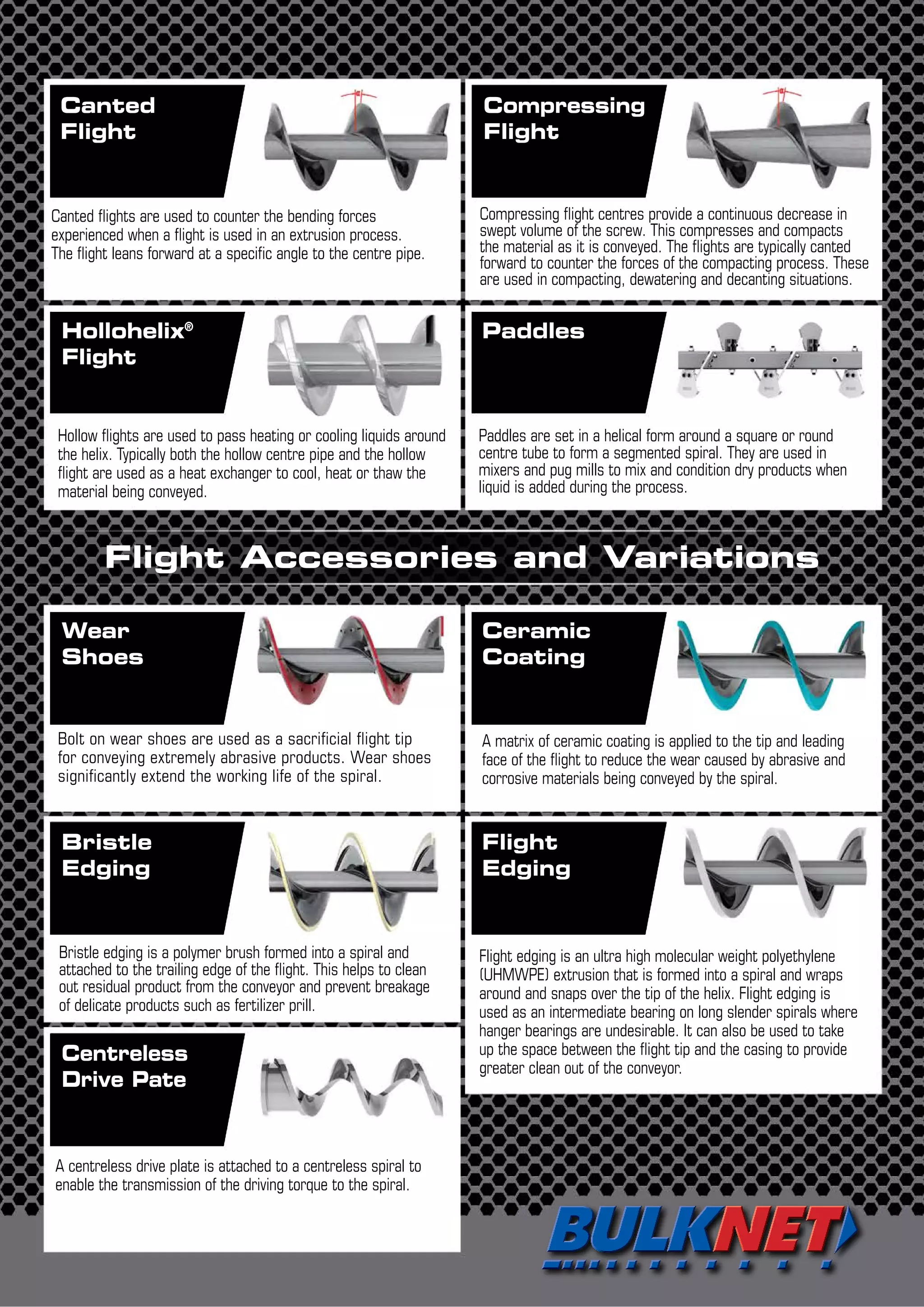

The document discusses various types of screw flights and auger blades used in applications like conveyors, foundations, and turbines. It describes common flight problems like misalignment and gaps. It then provides details on different flight types (variable pitch, integraleg, double start, etc.), accessories, materials, and BulkNet's advanced manufacturing process and large product range.