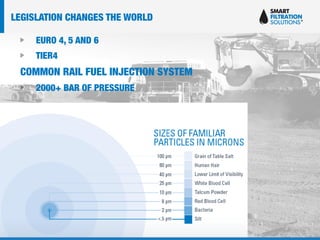

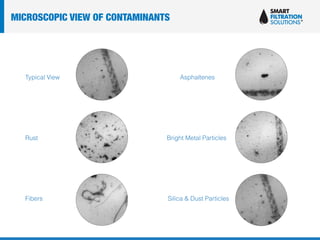

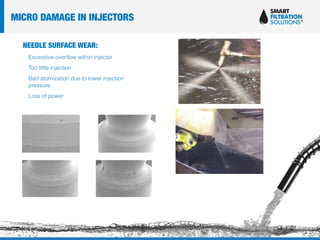

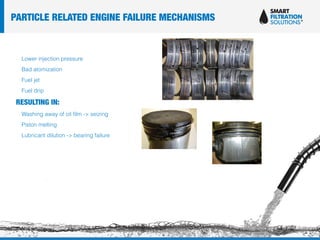

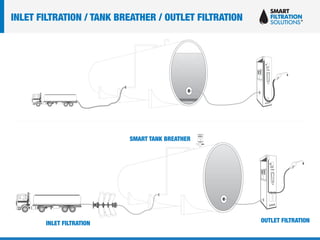

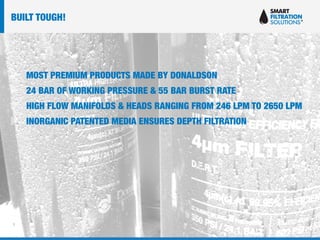

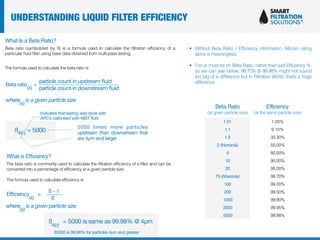

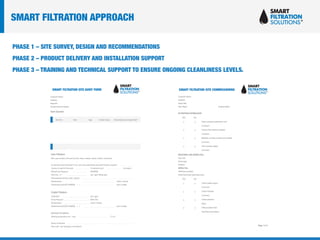

Enhanced Cleanliness - Optimum Performance Technology focuses on advanced filtration solutions to protect bulk fuel storage and expensive equipment from contaminants. The document discusses the causes and effects of fuel contamination, highlighting the importance of high-efficiency filters and maintaining cleanliness to prevent significant machinery issues. The company offers tailored filtration systems and support services to improve preventive maintenance practices for clients in the USA and UAE.