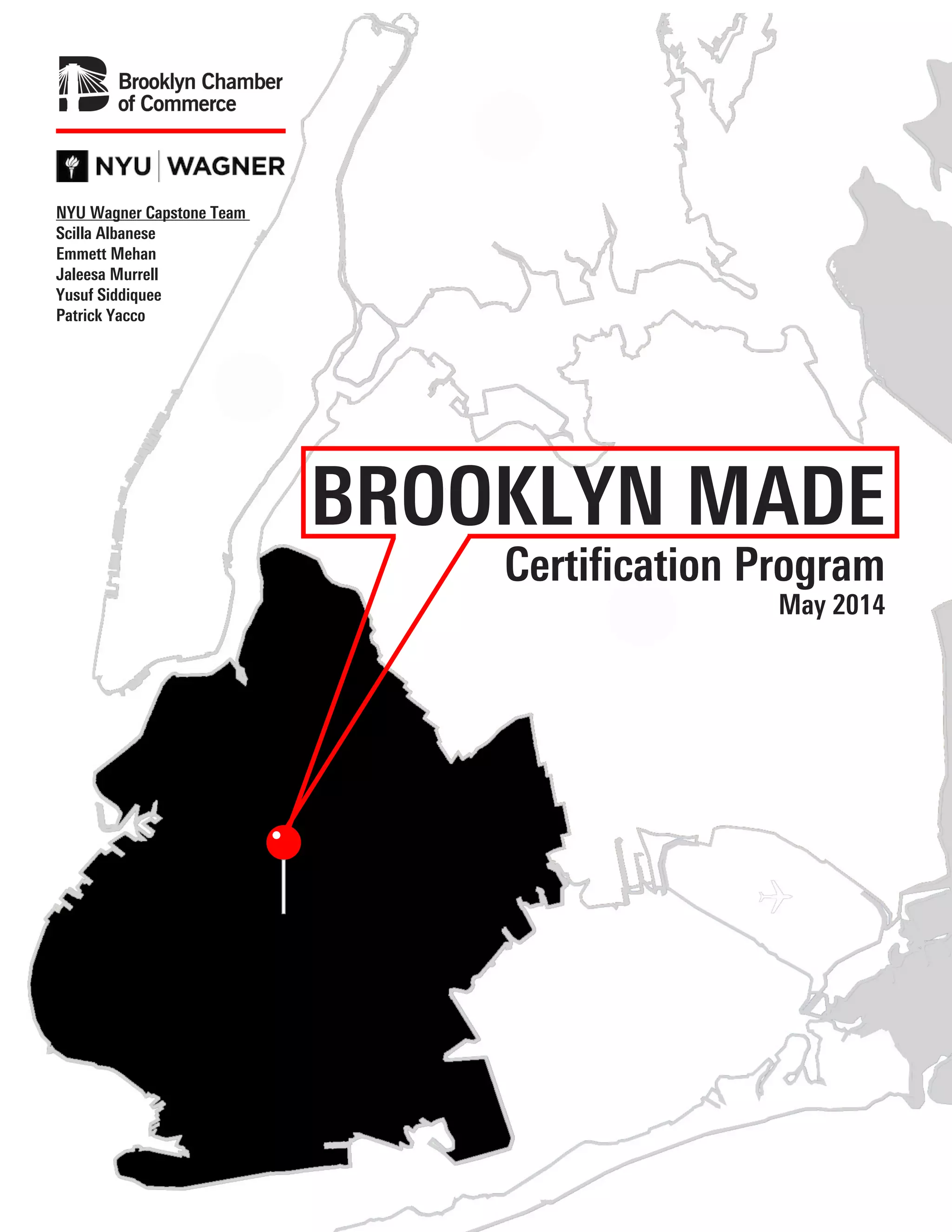

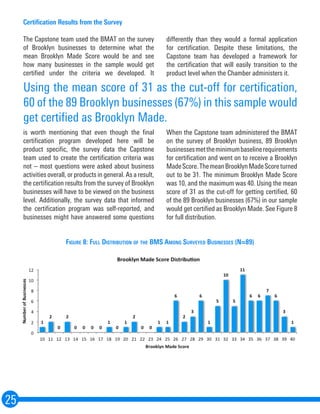

This document discusses the background research conducted for developing a Brooklyn Made certification program. It provides context on economic trends in Brooklyn's manufacturing sector, which experienced a loss of jobs from 2000-2011 but a small increase from 2010-2013. It notes that while manufacturing jobs have declined nationwide and in New York City, Brooklyn has seen growth in smaller specialty producers. The certification aims to differentiate authentic Brooklyn-made products and benefit local businesses by combating brands that falsely claim Brooklyn affiliation.