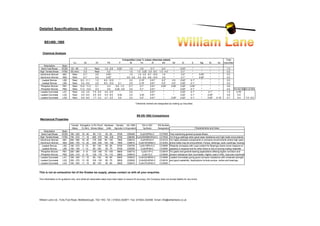

This document provides information on various brass and bronze alloys, including their chemical composition ranges, mechanical properties, characteristics, uses, and comparative standards. It lists 12 alloys - sand cast brass, high tensile brass, two types of aluminium bronze, two types of leaded bronze, two types of phosphor bronze, and three types of leaded gunmetal. For each alloy, it specifies the typical ranges for major elemental components like copper, tin, zinc, and lead, as well as mechanical properties like tensile strength and hardness. It also gives brief descriptions of key characteristics and common applications for each grade.