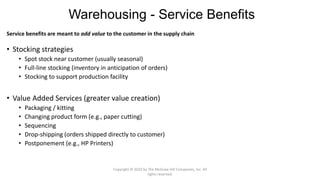

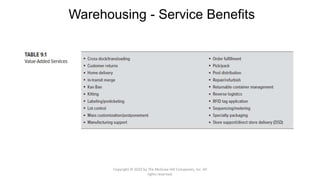

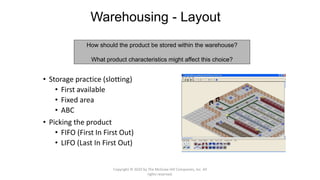

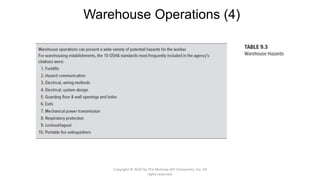

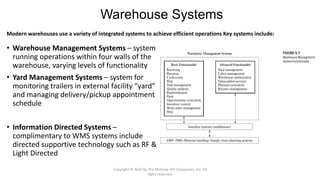

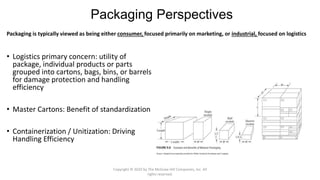

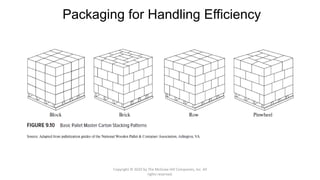

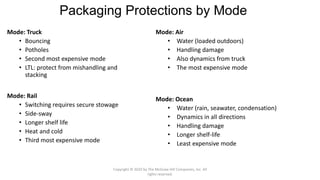

Warehousing, materials handling, and packaging are interrelated functions that impact the entire supply chain. Modern warehousing requires strategic planning to efficiently meet customer needs. Materials handling involves selecting automated or semi-automated systems depending on the application. Packaging balances logistics needs for protection and efficiency with communication functions. Together these areas aim to lower costs and enhance customer service across transportation and storage operations.