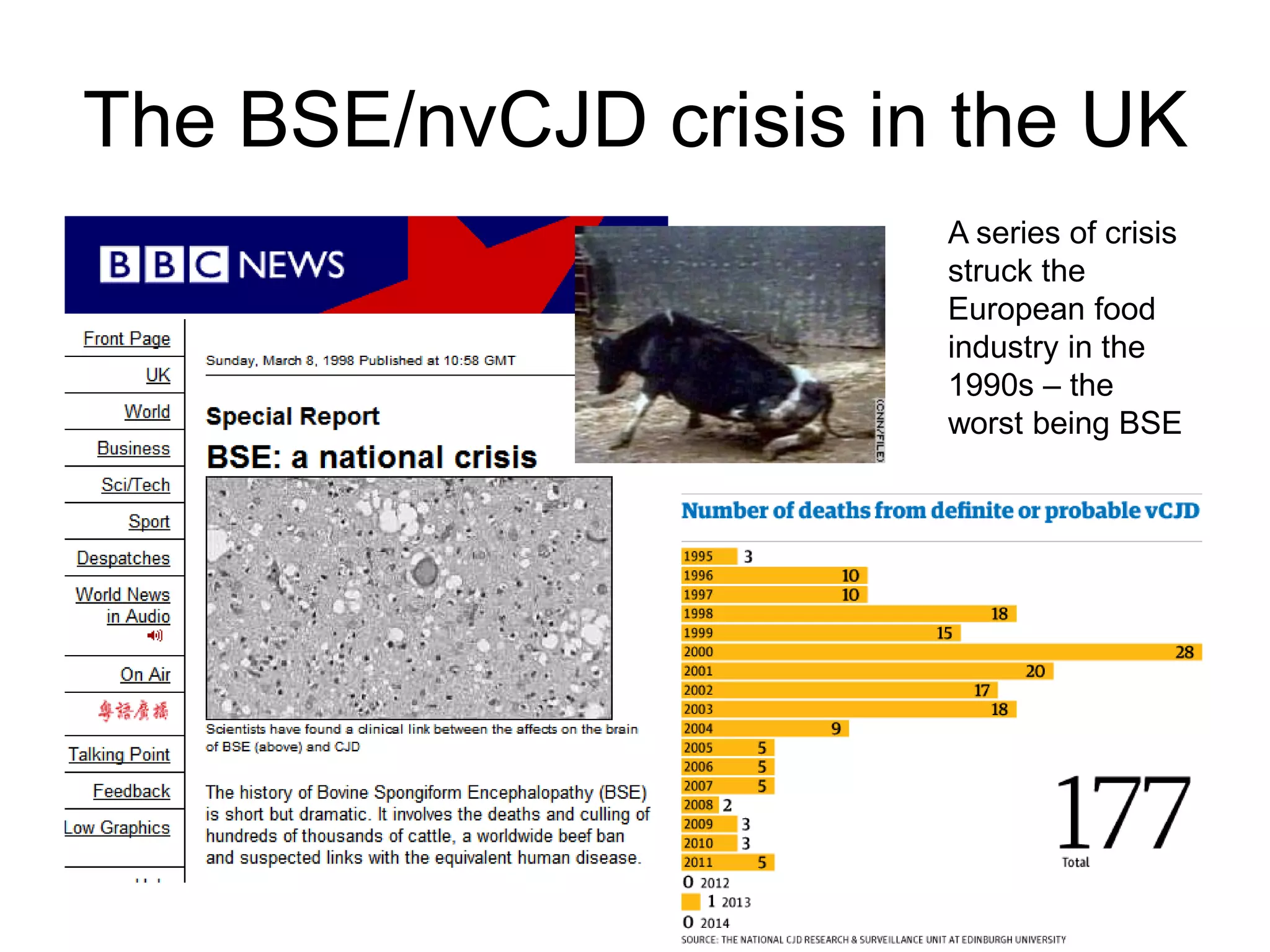

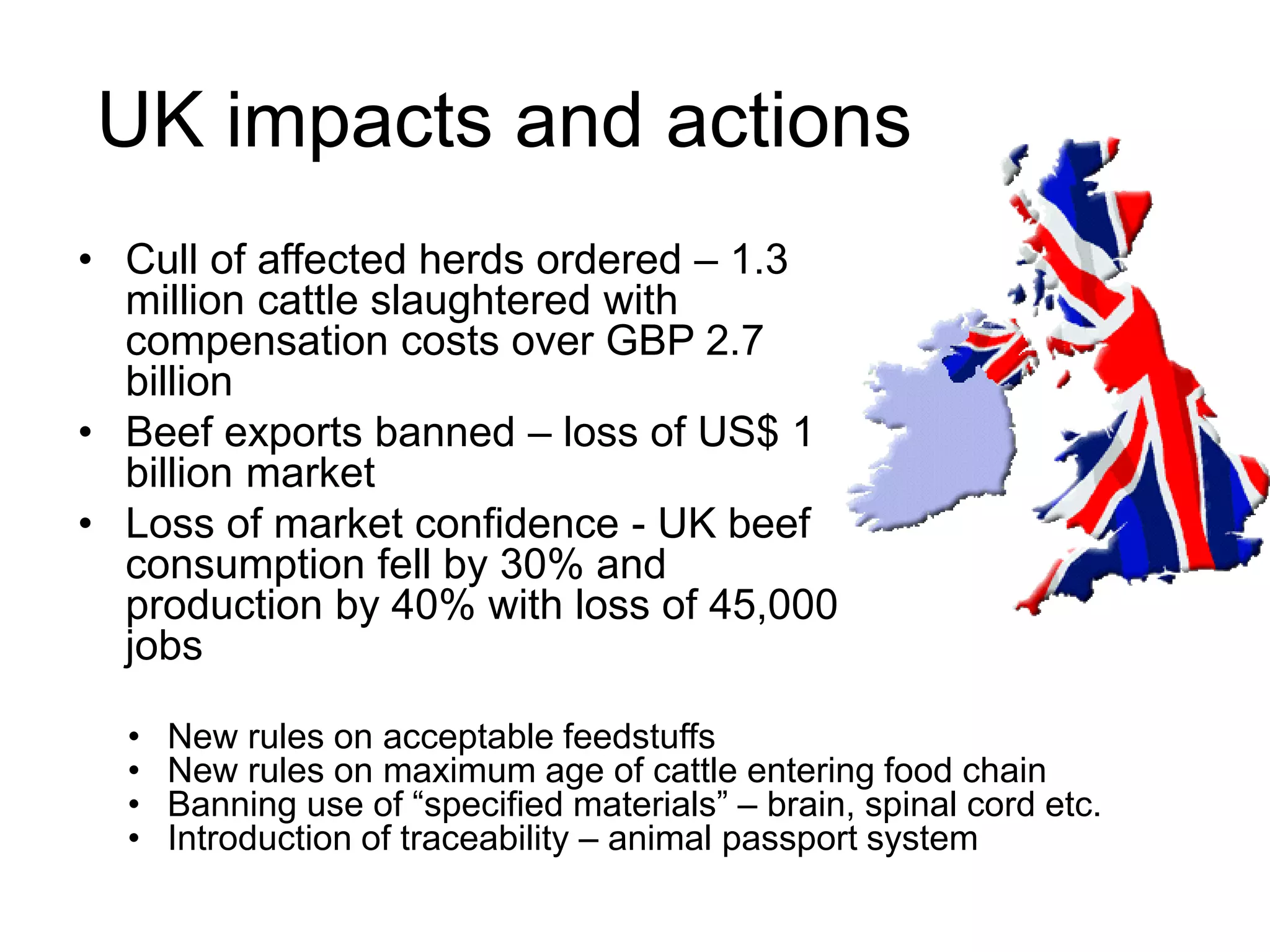

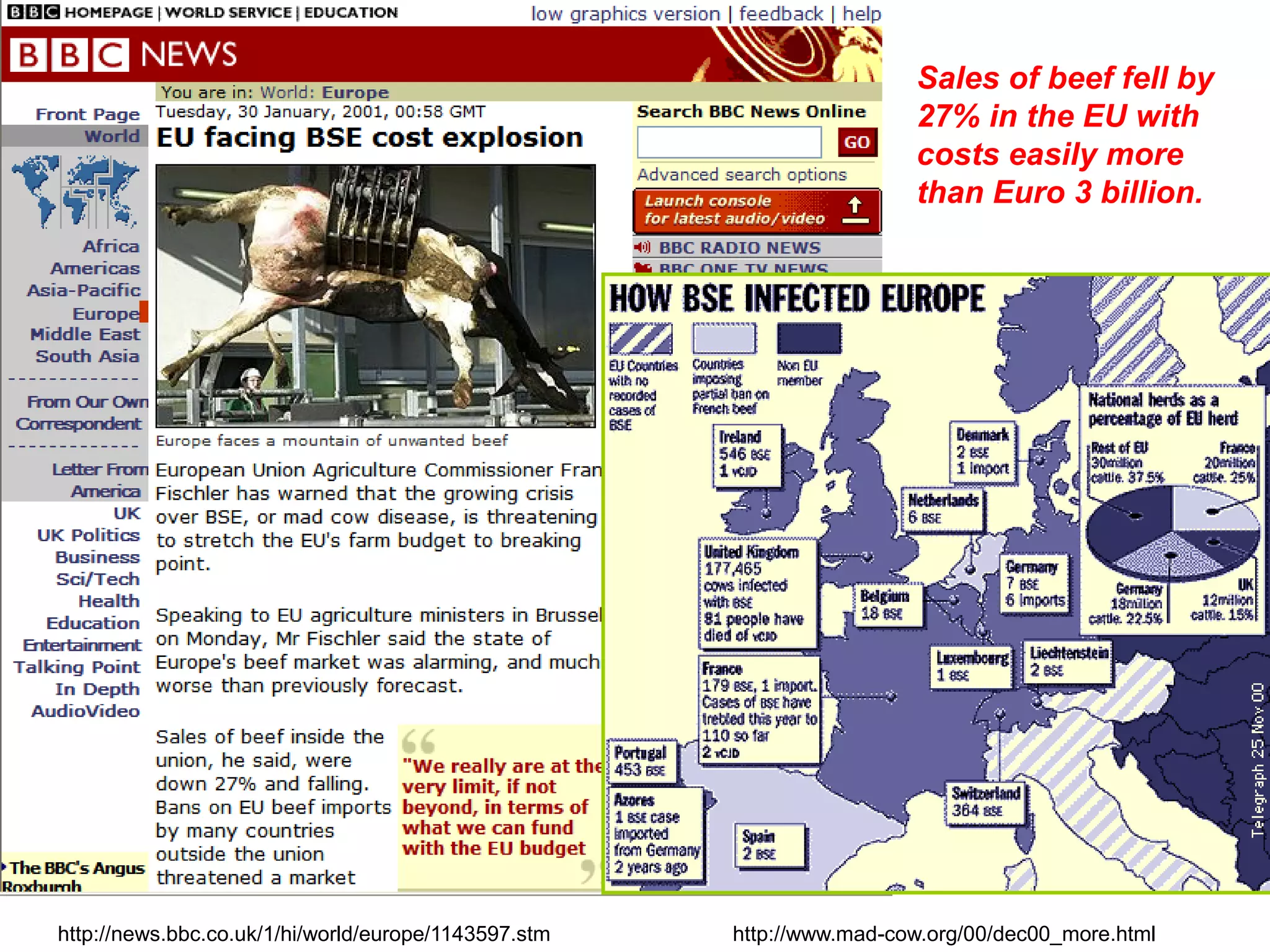

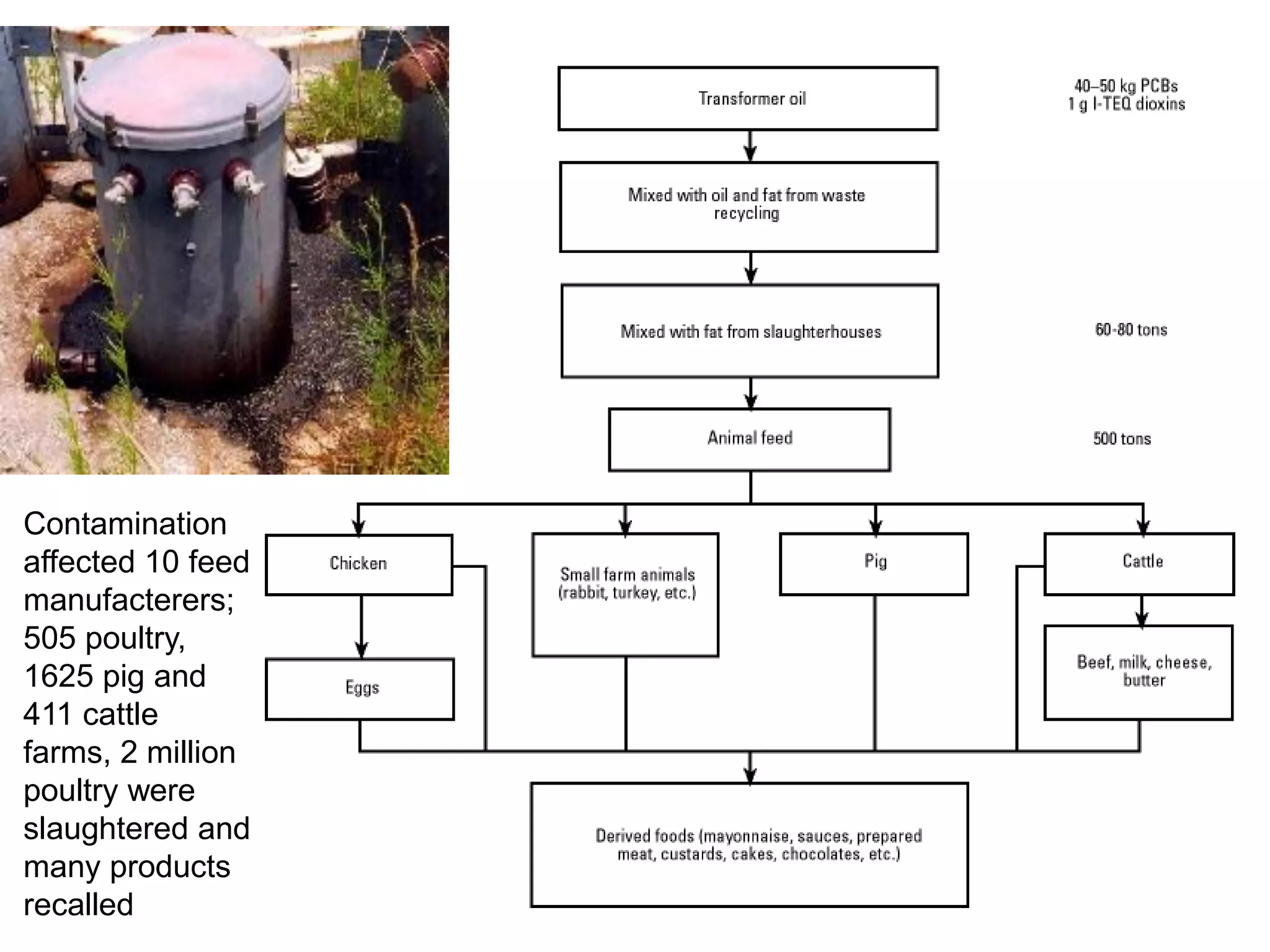

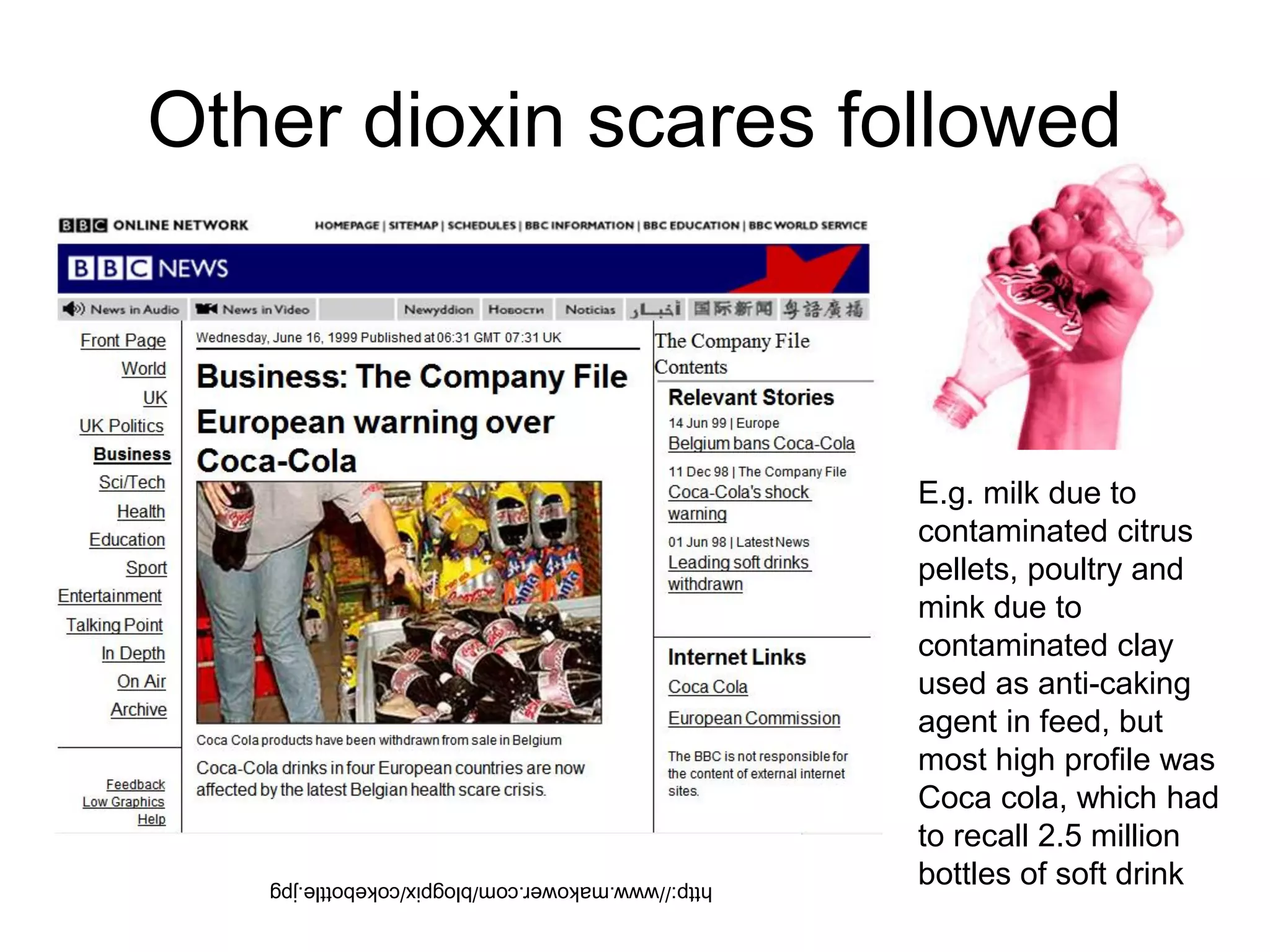

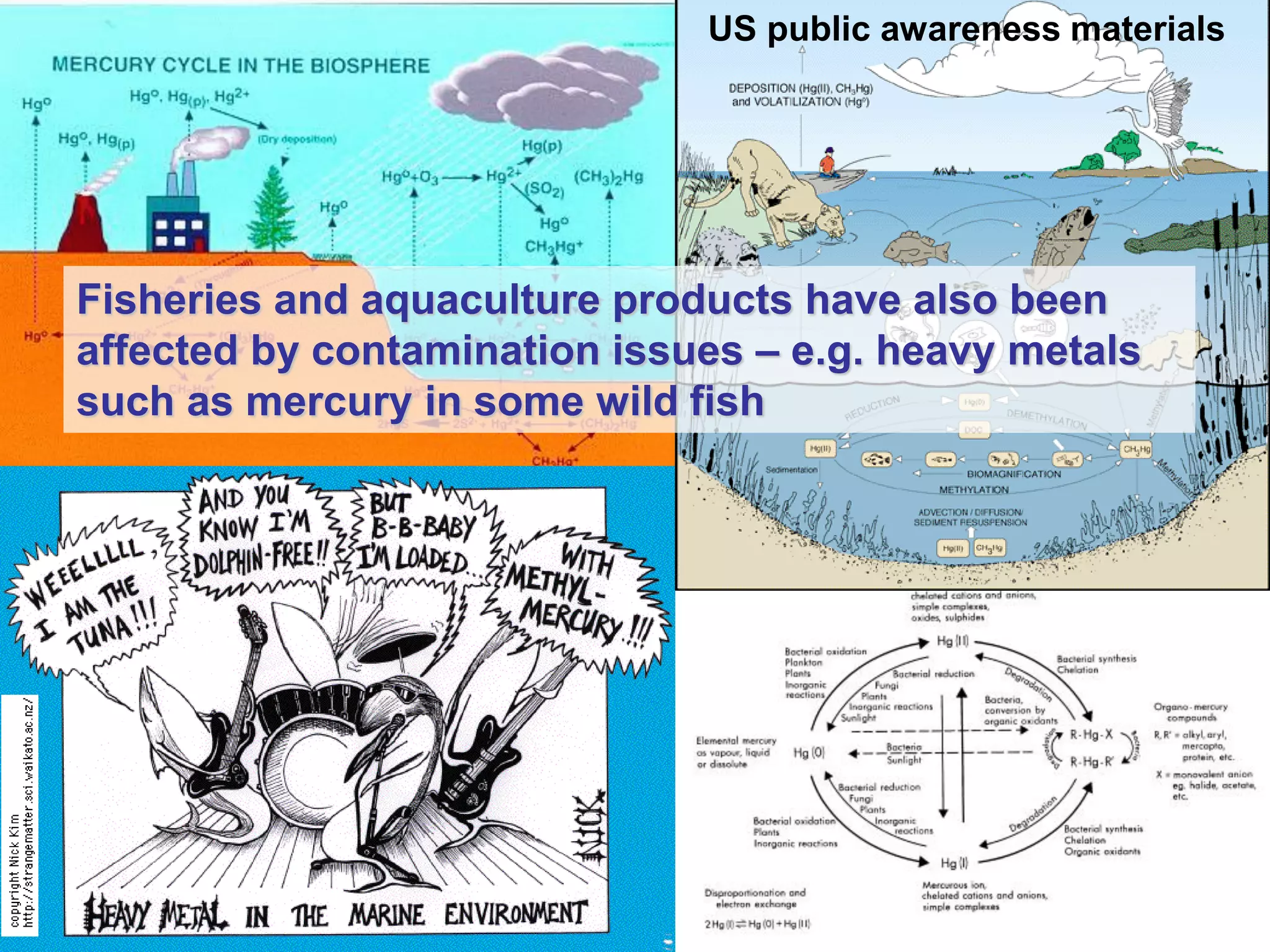

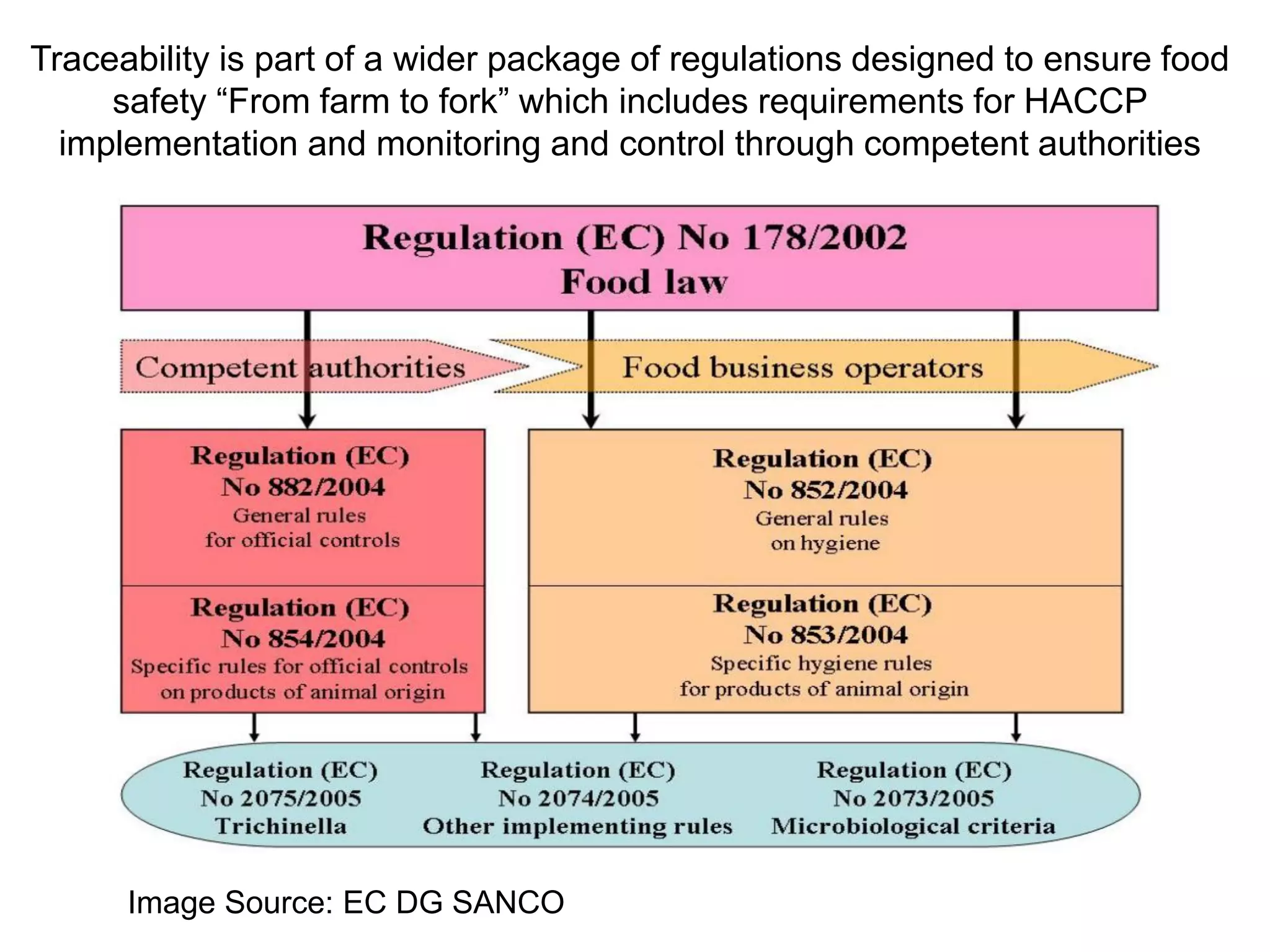

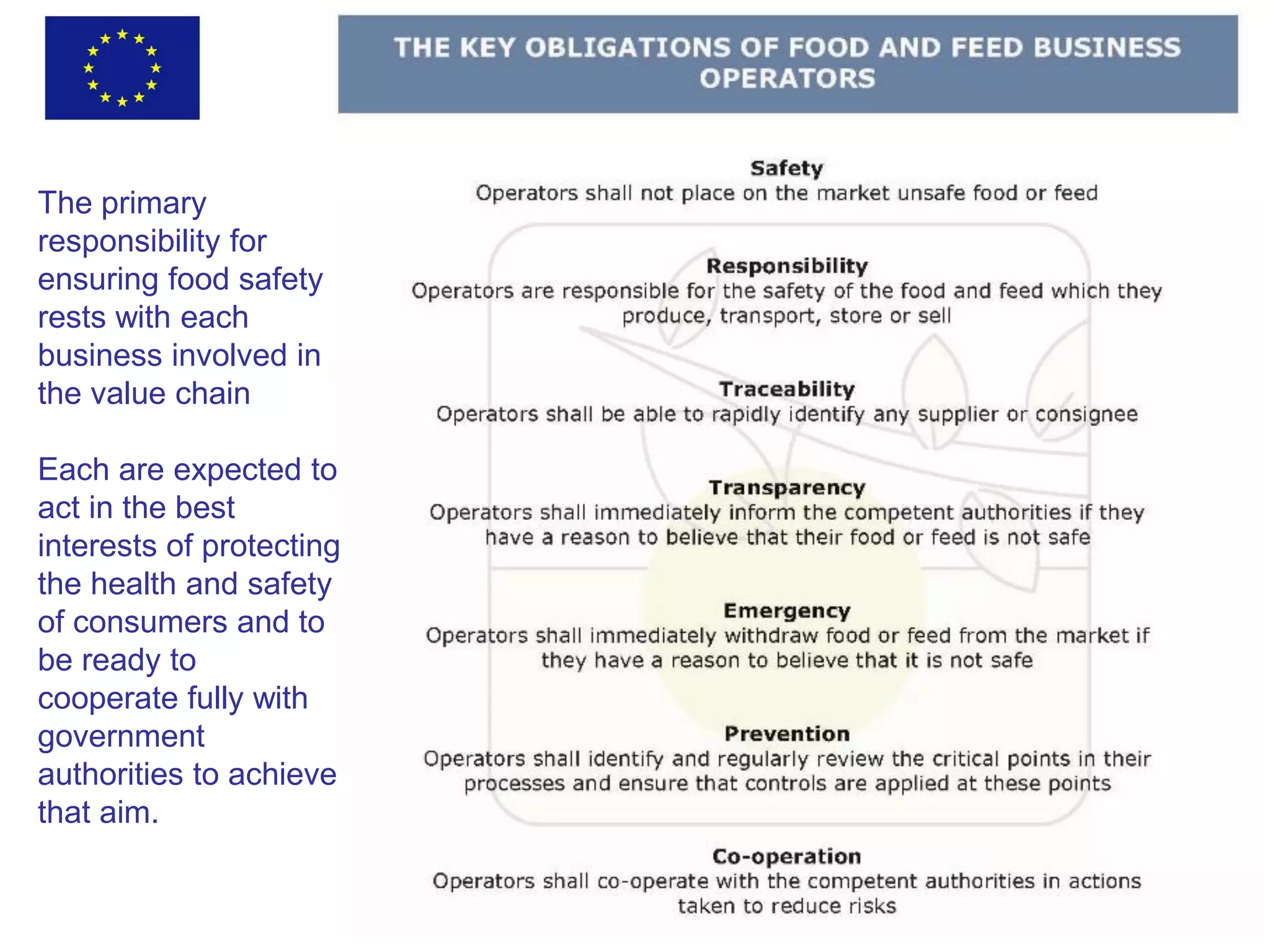

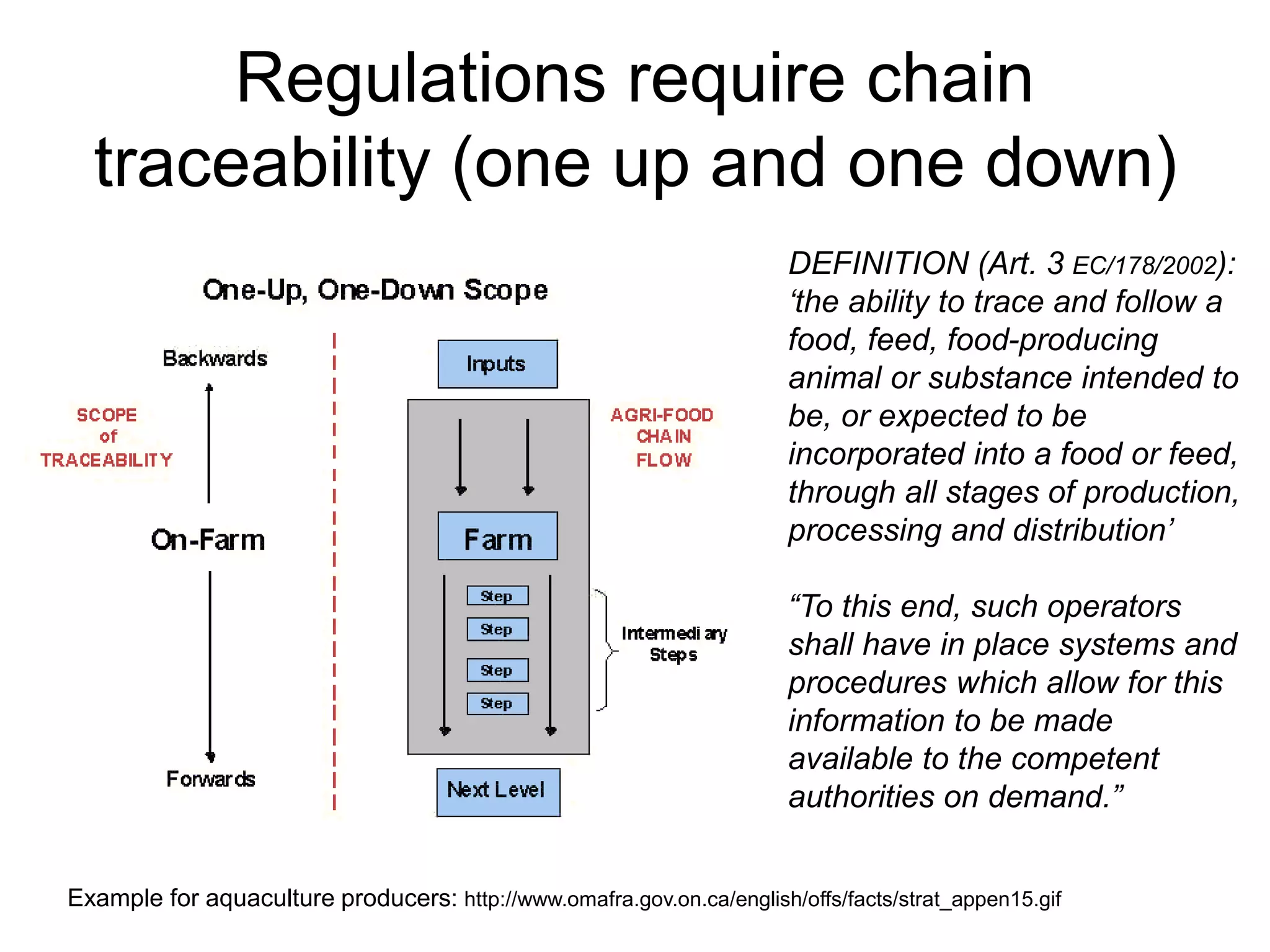

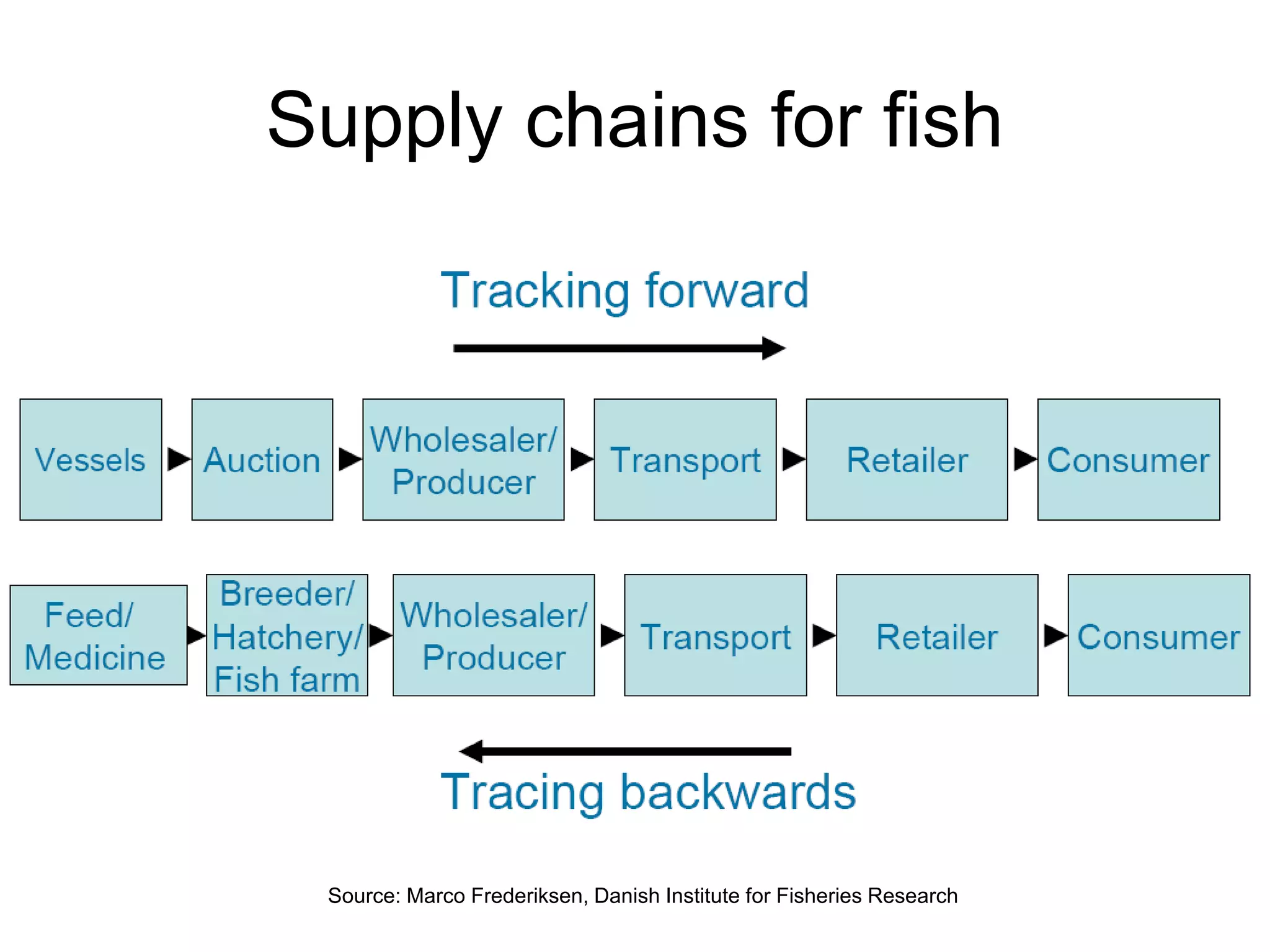

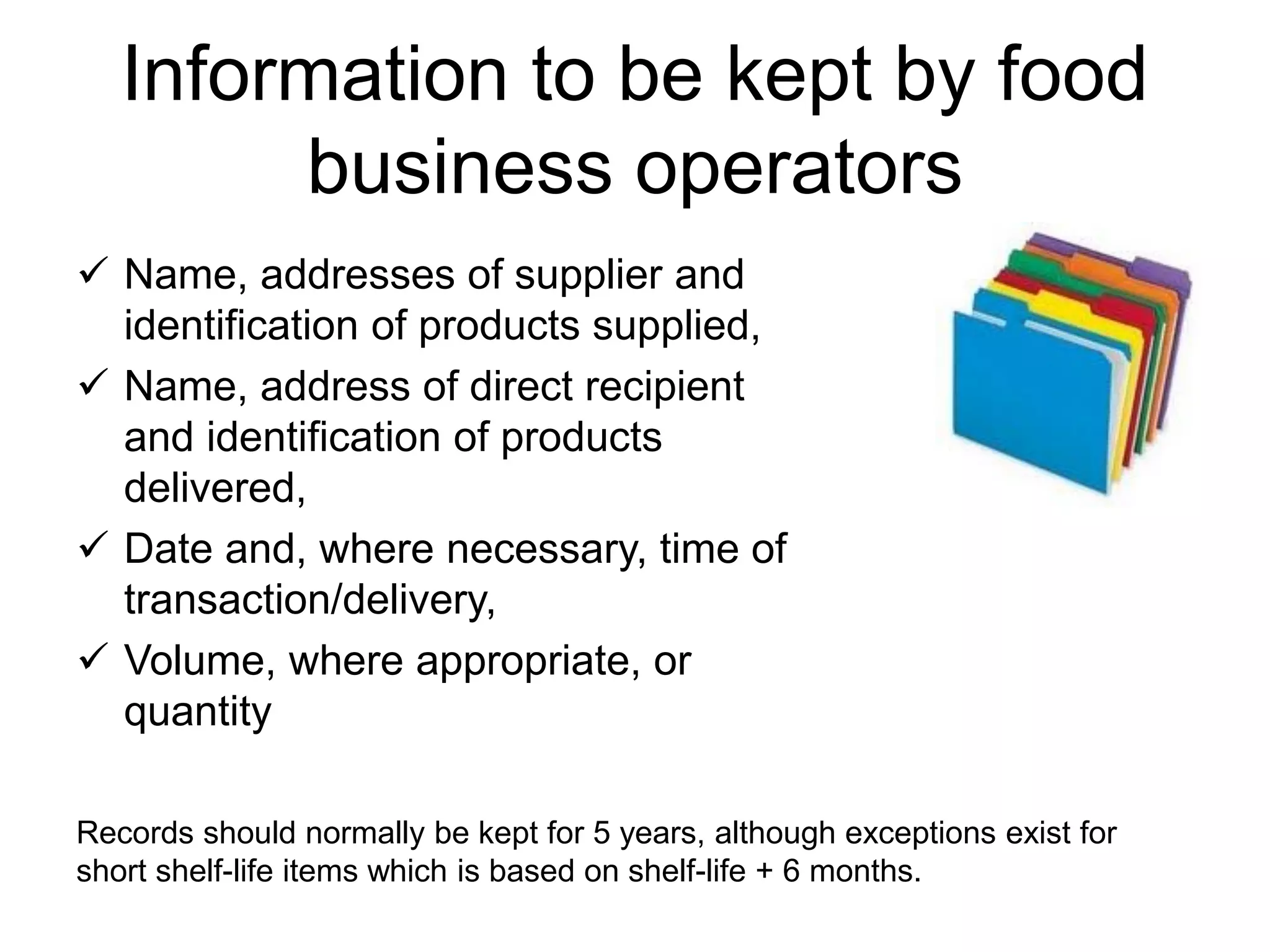

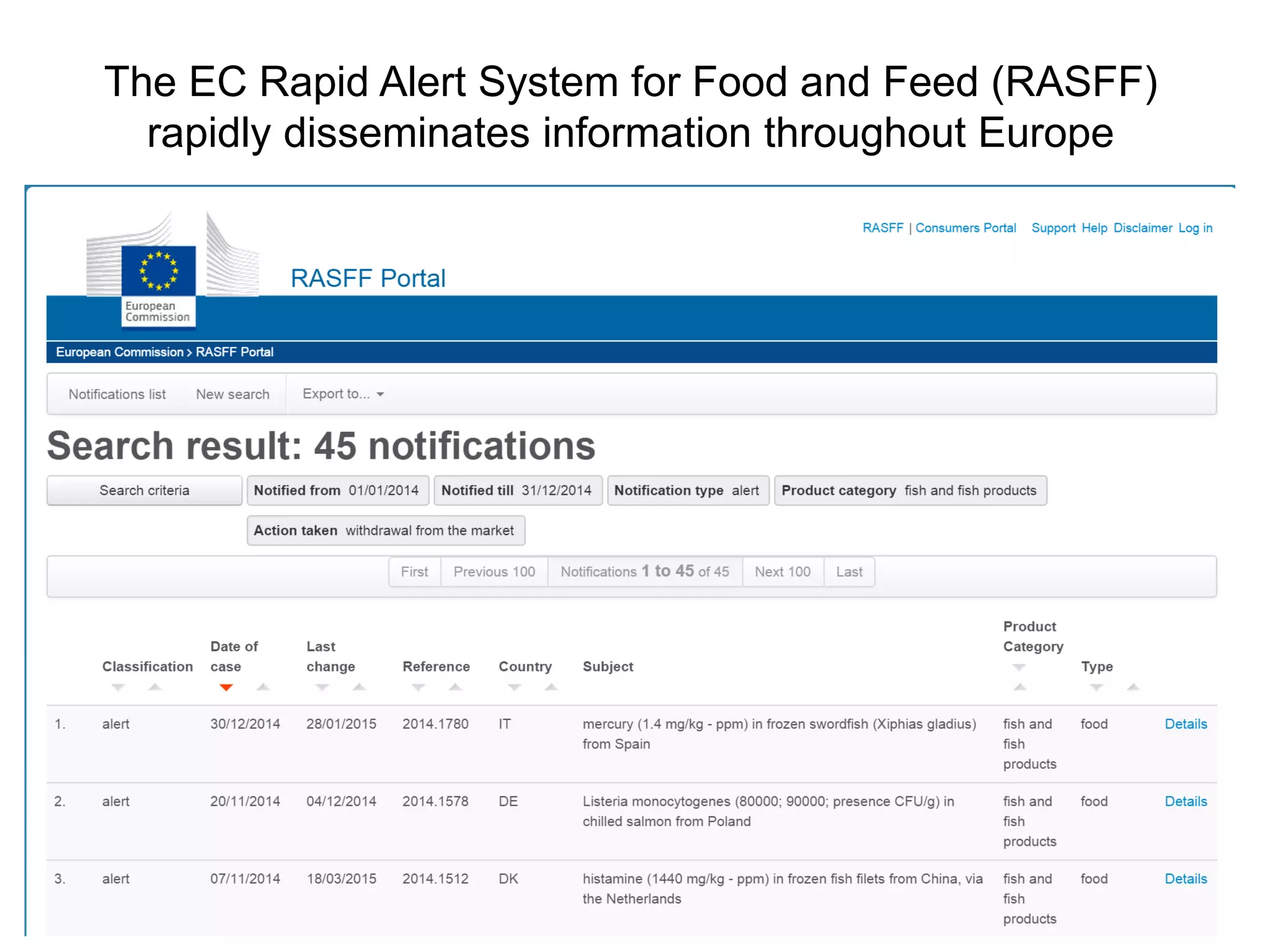

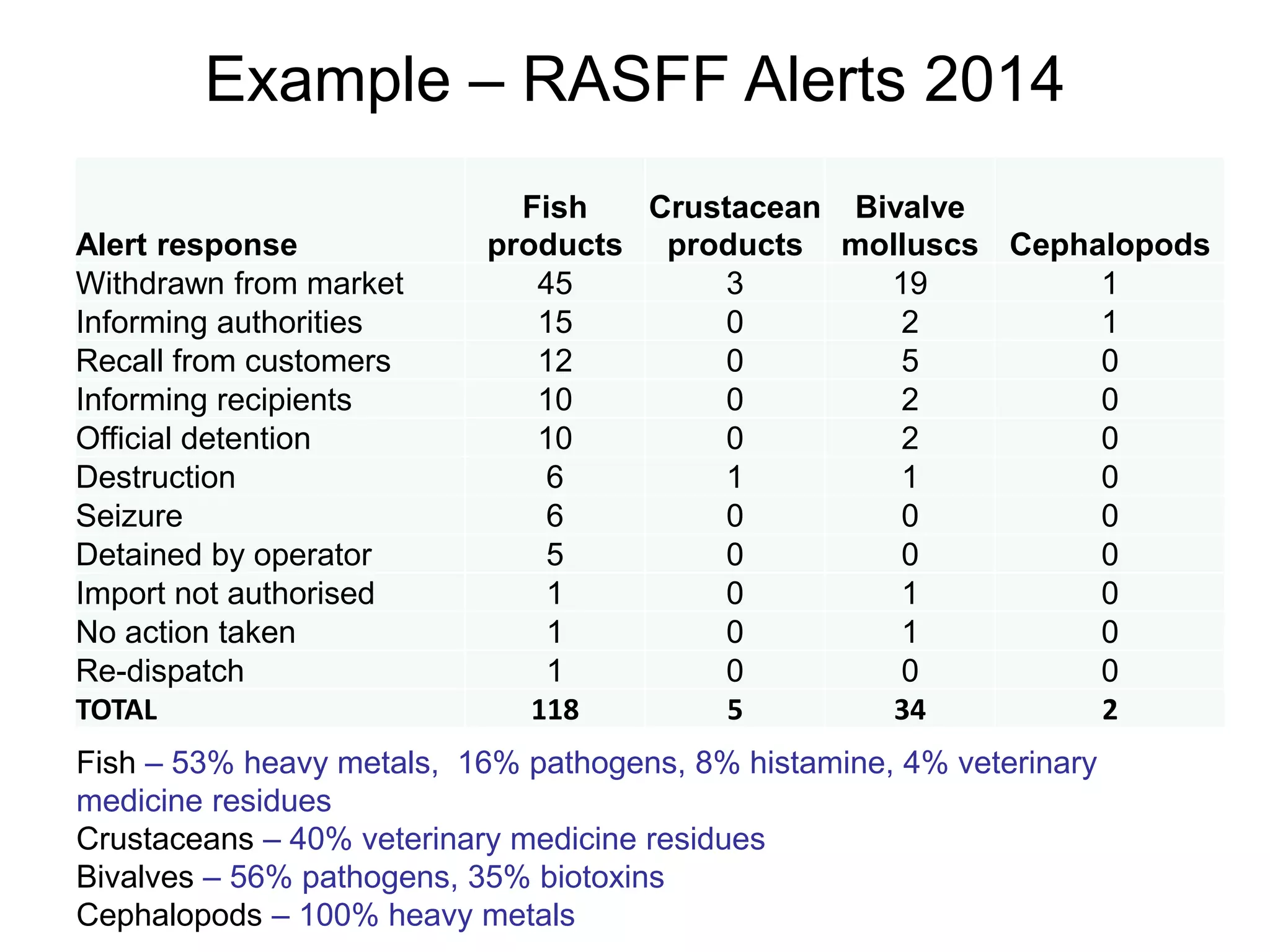

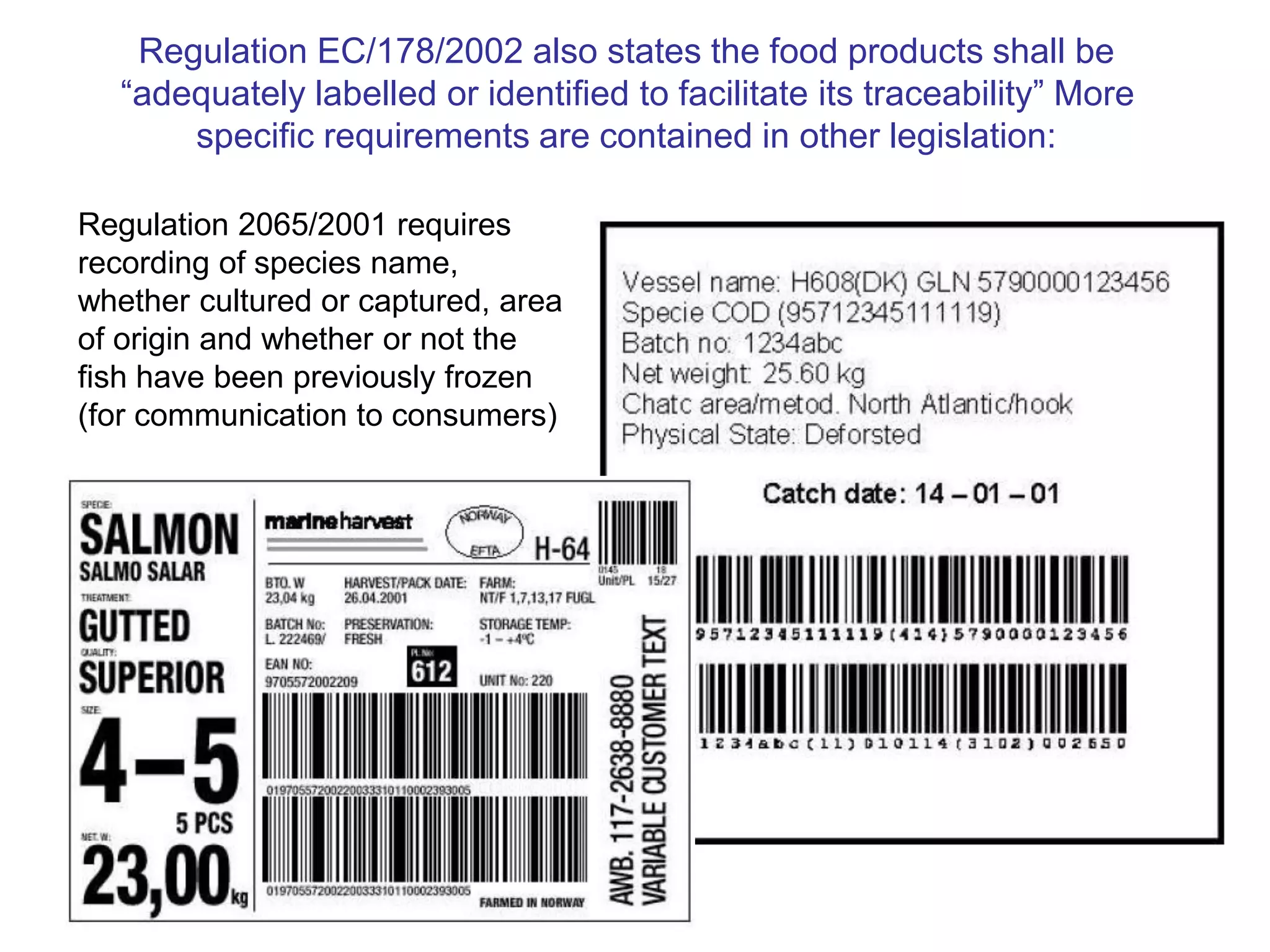

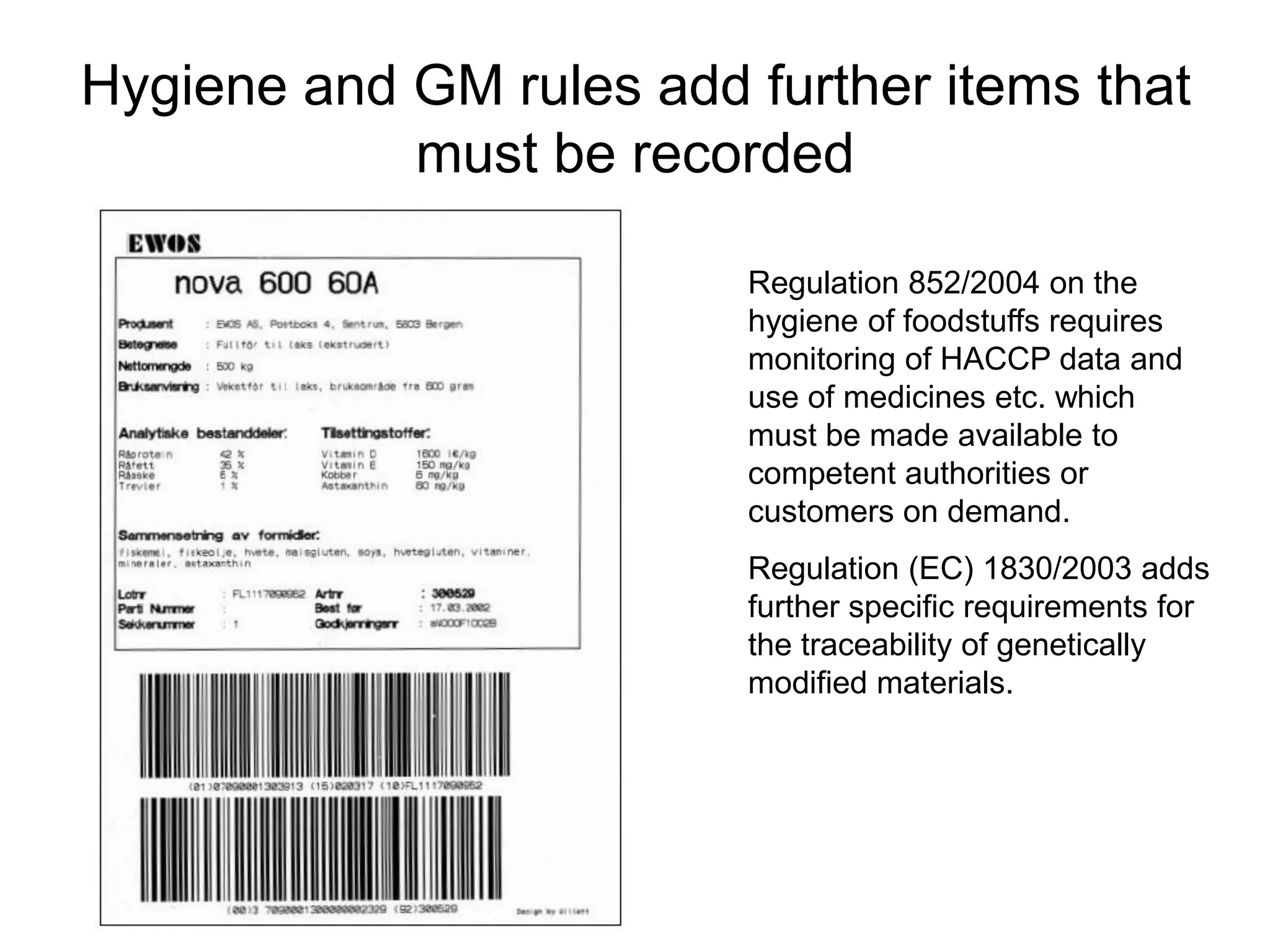

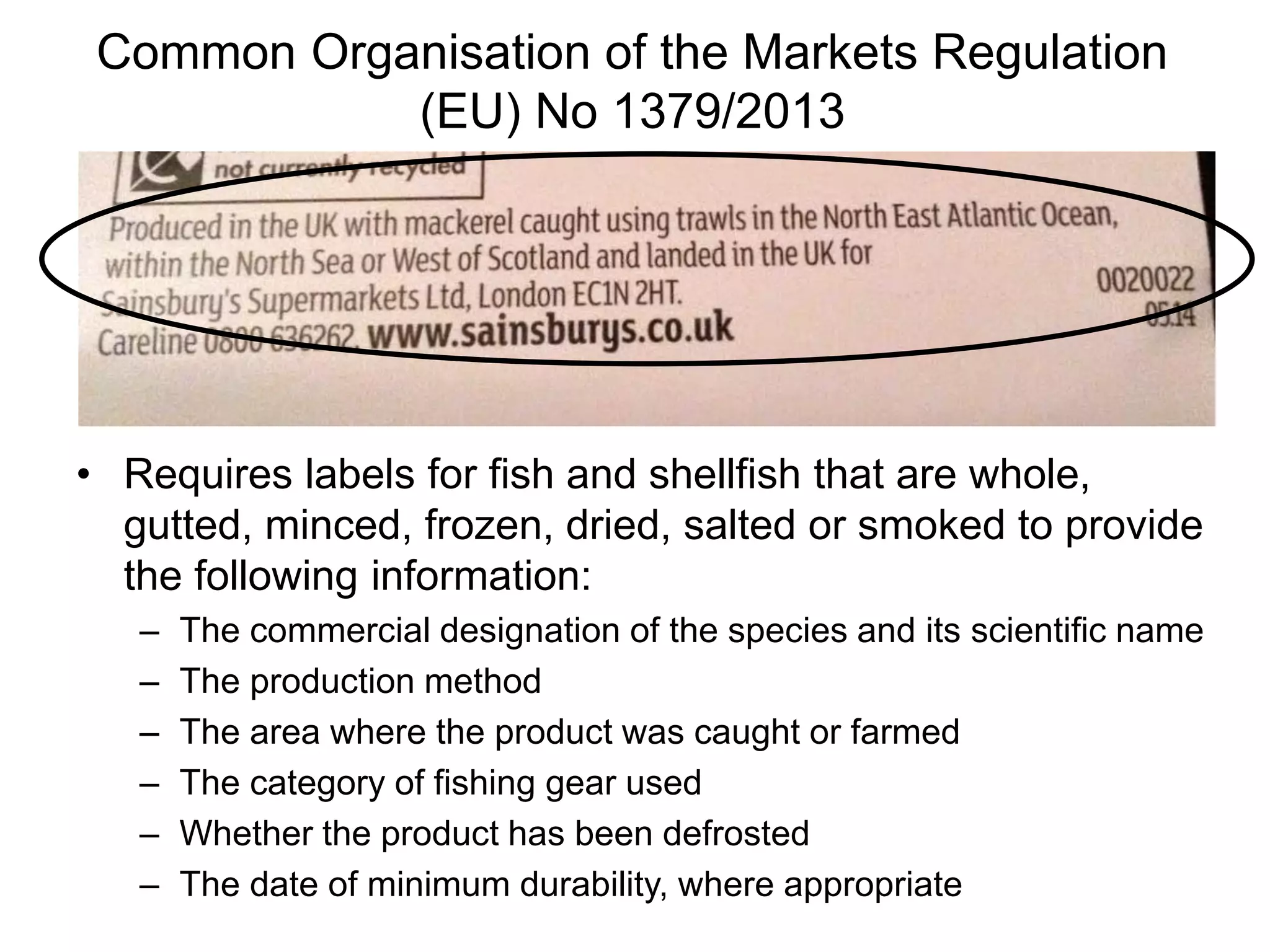

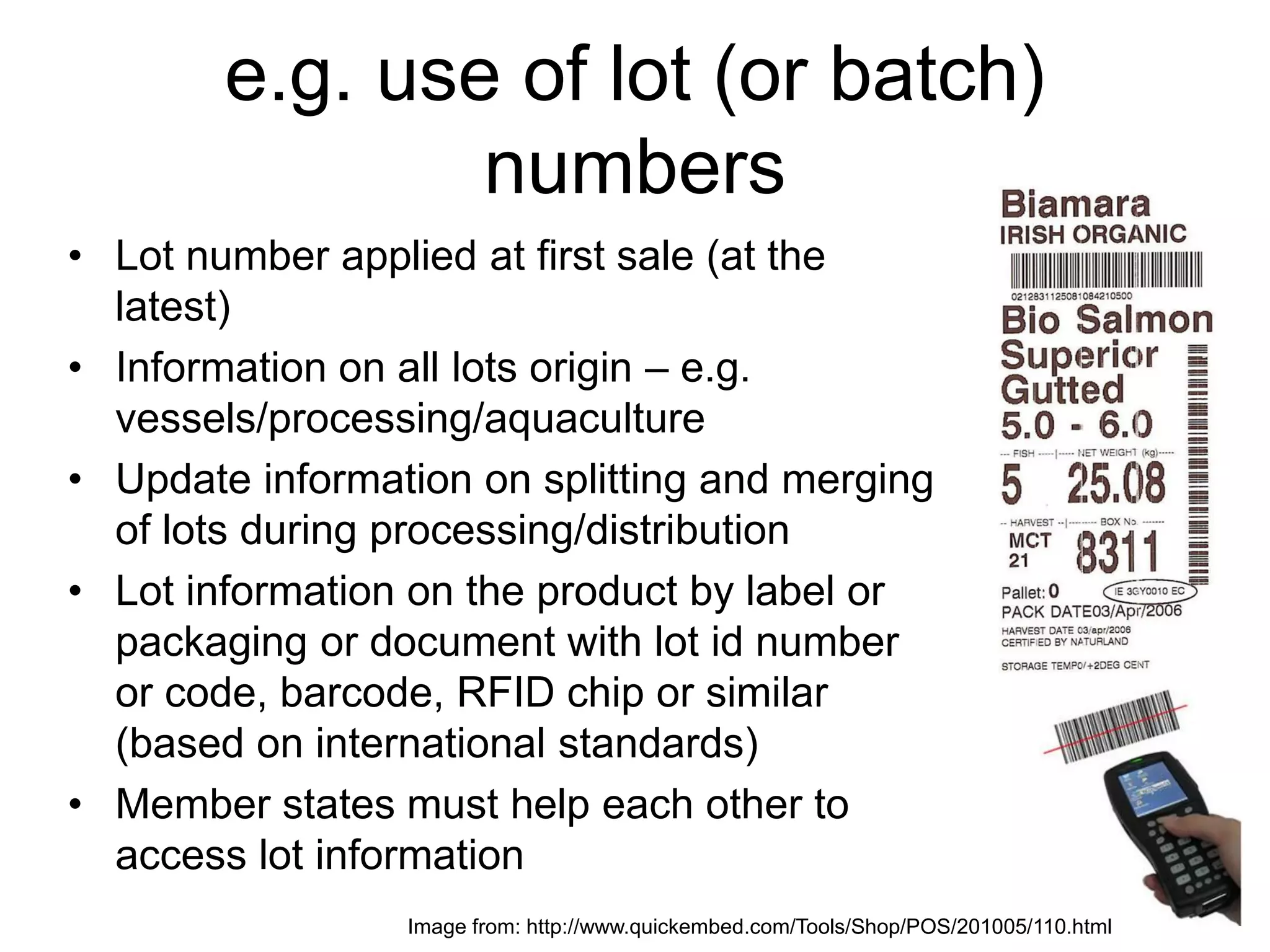

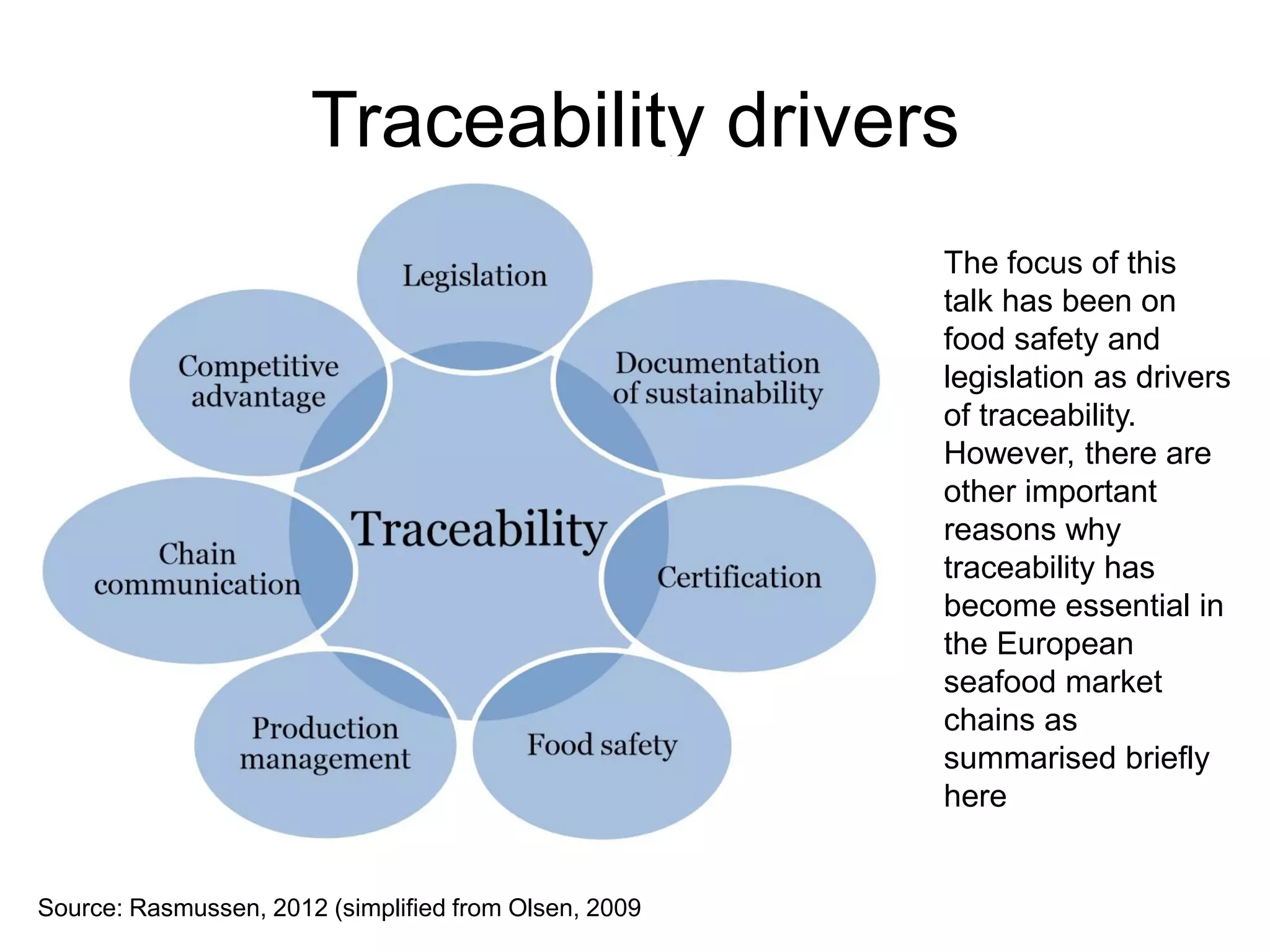

The document discusses the development and implementation of European regulations for food traceability, primarily driven by major food safety crises in the 1980s and 1990s, such as the BSE outbreak. It outlines the regulatory framework established by the EU, including the introduction of traceability systems, and emphasizes the importance of maintaining consumer trust and safety throughout the food supply chain. Key regulations and their requirements for transparency and traceability in seafood and aquaculture are also highlighted.