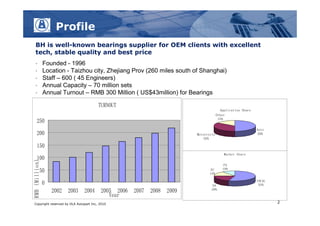

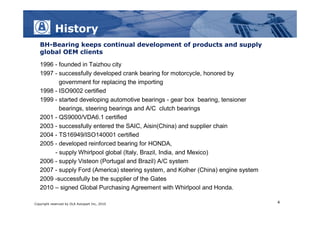

Zhejiang BH Bearing Co.,Ltd is a leading bearings supplier founded in 1996 in Taizhou, China with over 600 employees. It has an annual capacity of 70 million bearings sets and annual revenue of RMB 300 million. BH supplies a variety of automotive and other bearings to global OEM clients such as Honda, Ford, and Whirlpool. It has established quality systems, R&D capabilities, and a US office to provide local support to North American clients.