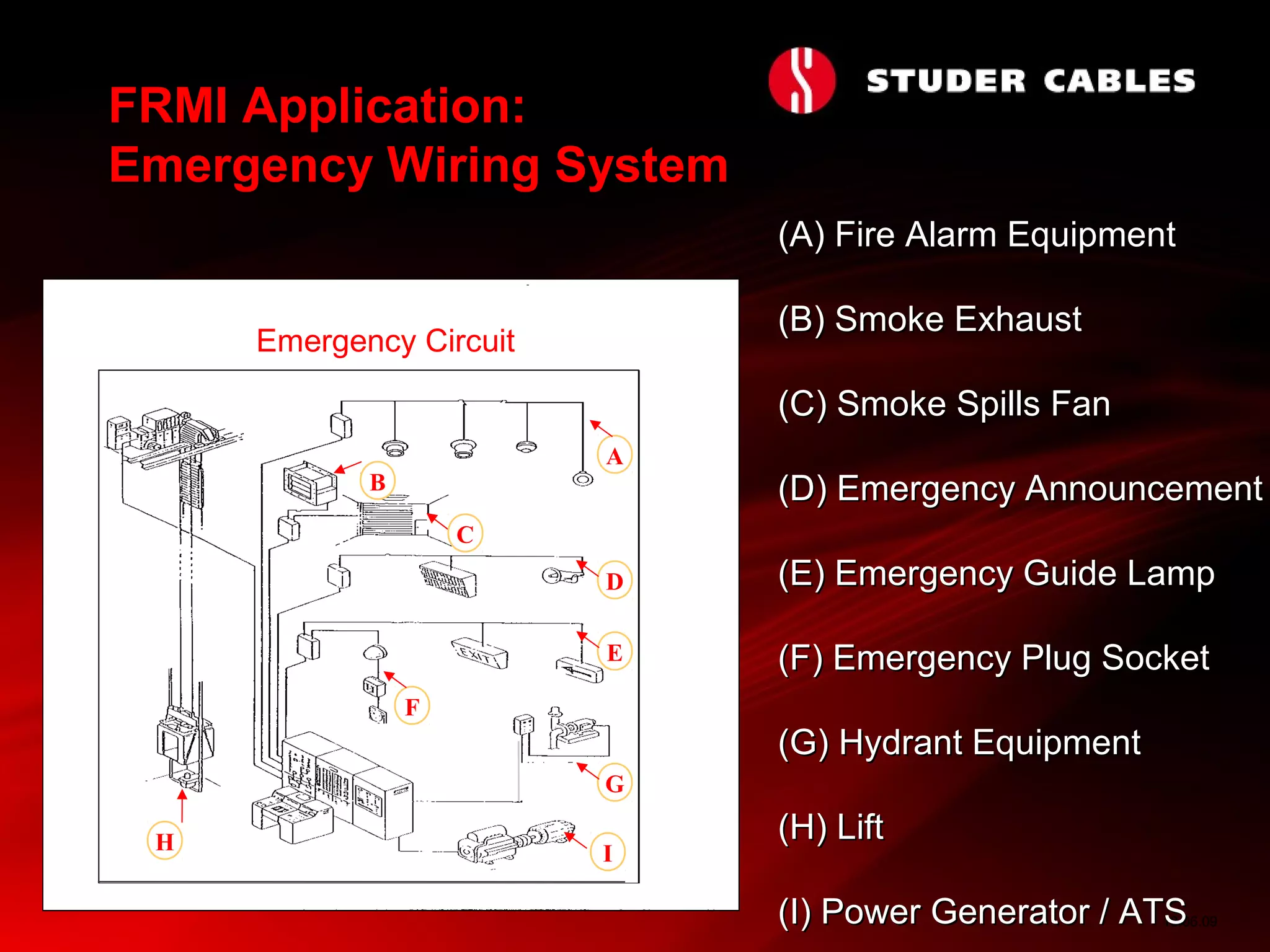

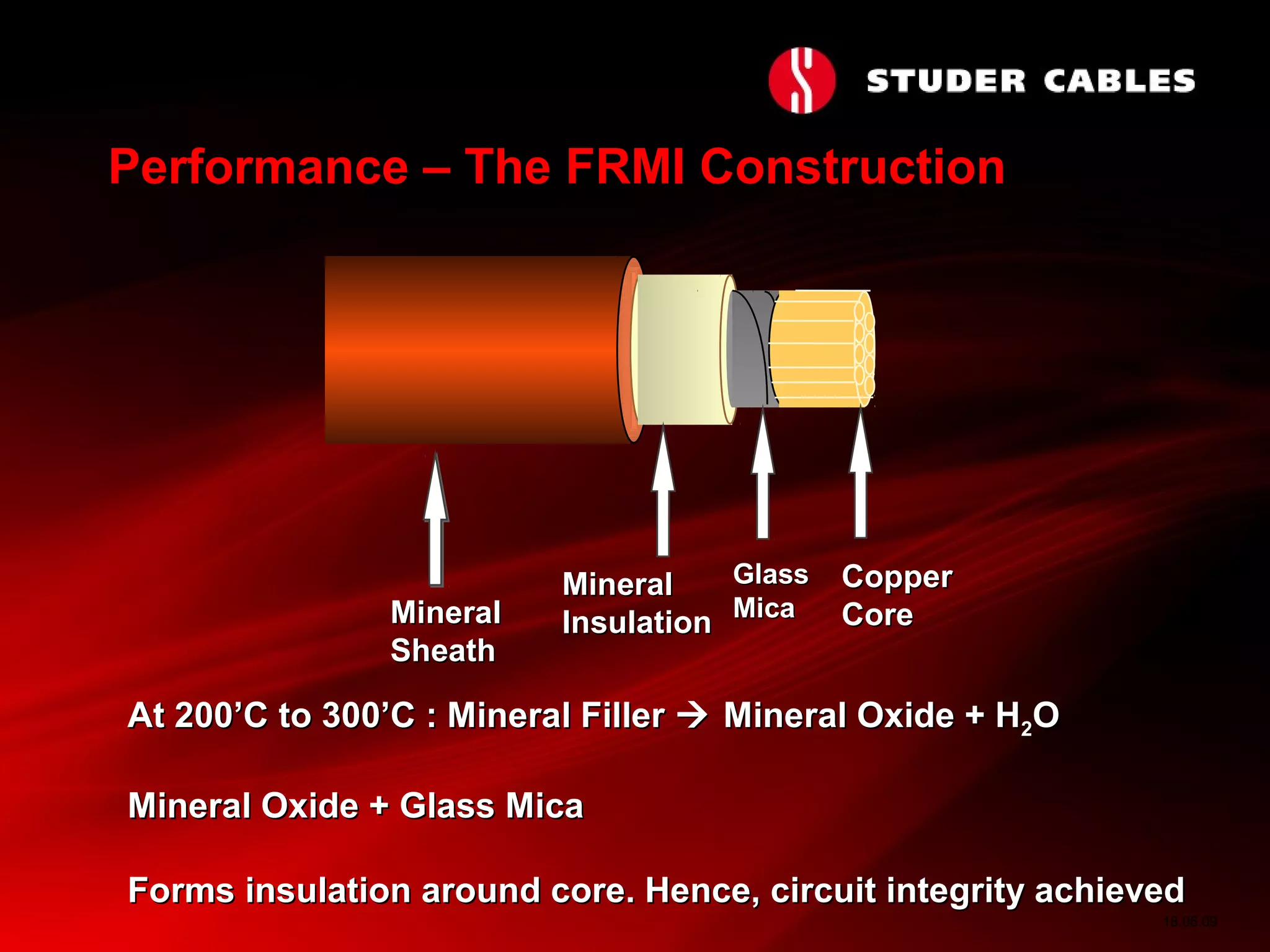

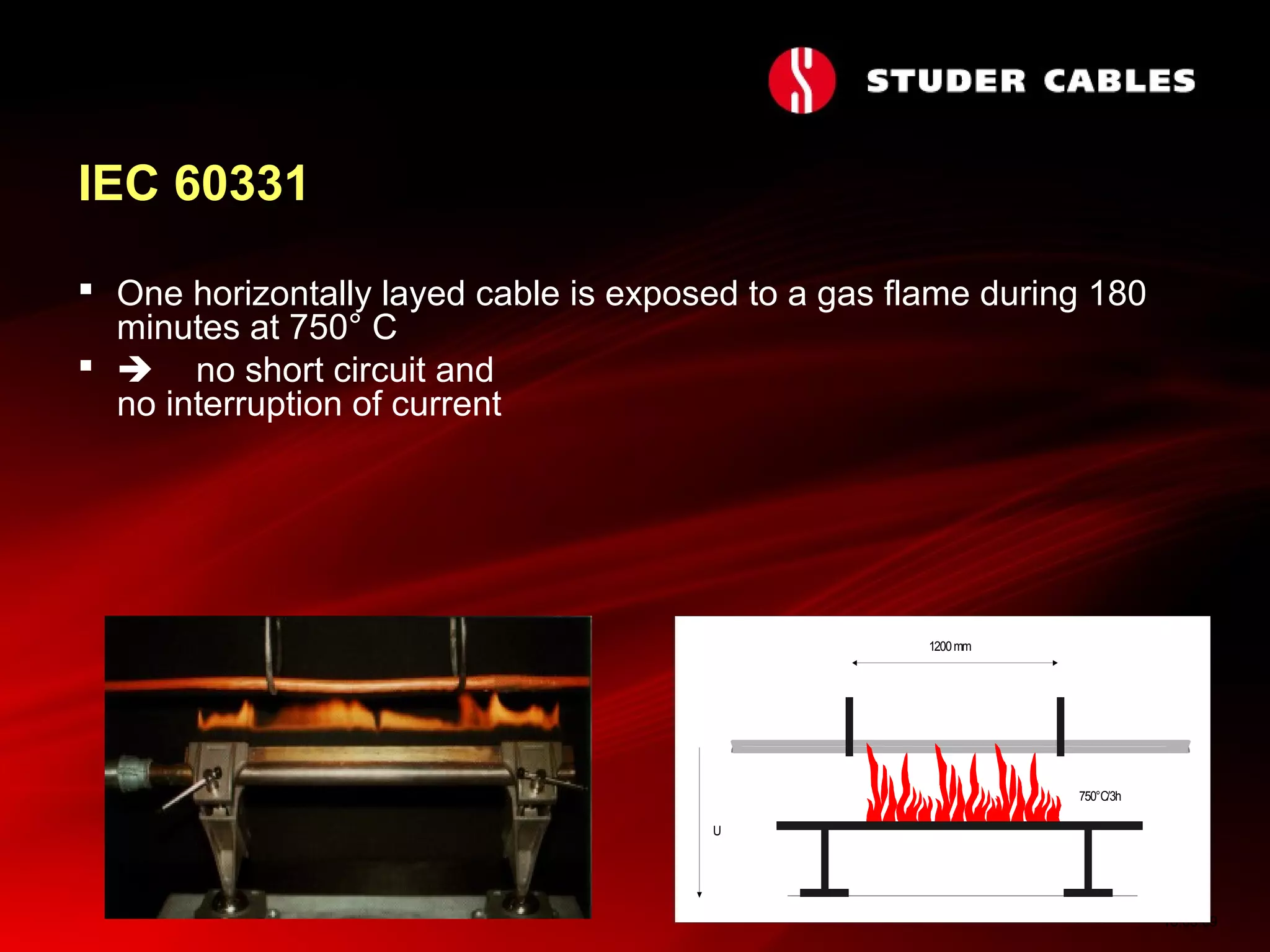

Betaflam mineral insulated cable is fire resistant and can maintain circuit integrity when exposed to extreme heat and fire conditions, as tested by various international standards. It has applications in emergency wiring systems of high-rise buildings, hospitals, airports, and tunnels. The cable's mineral insulation and copper core allow it to withstand temperatures over 1000°C without causing short circuits or current interruptions, making it suitable for ensuring operational critical systems remain powered during fires. Prevention through the use of flame retardant and self-extinguishing materials is emphasized as the best approach to fire safety.

![18.06.09

Building Fire!!

0 30 60 90 120 150 180

500

1000

[K]T-T0

[min]

• Fire temperature will flash over to

950’C in any building environment

in accordance to IEC216

• Fire propagations via flammable

building materials

• Thick smoke will suffocate and block

visibility

• Halogen gases will irritates human’s

body and destroy equipment

• High content of toxic gases which

is hazardous and life threatening](https://image.slidesharecdn.com/betaflam-150131033757-conversion-gate01/75/Betaflam-3-2048.jpg)