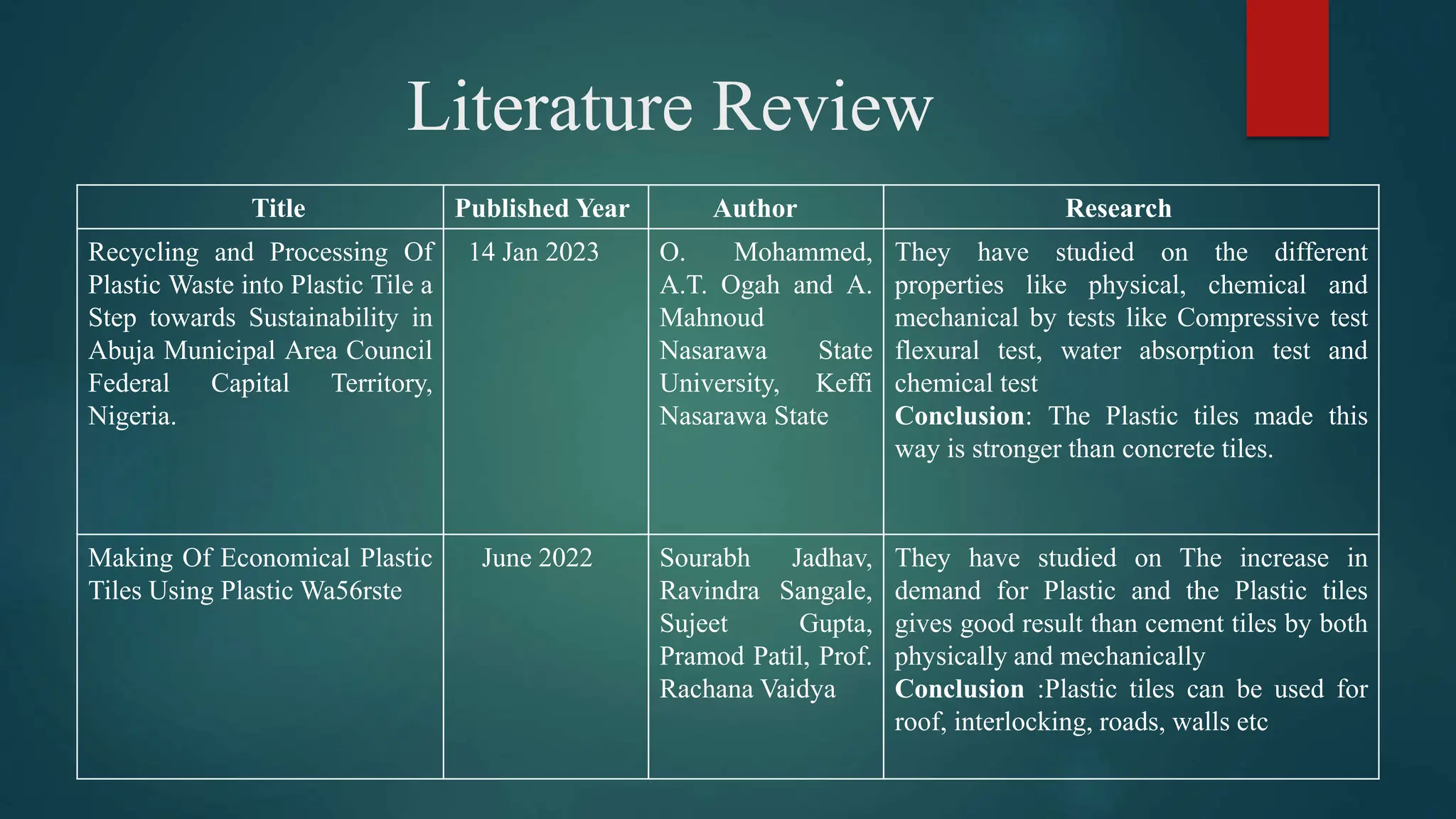

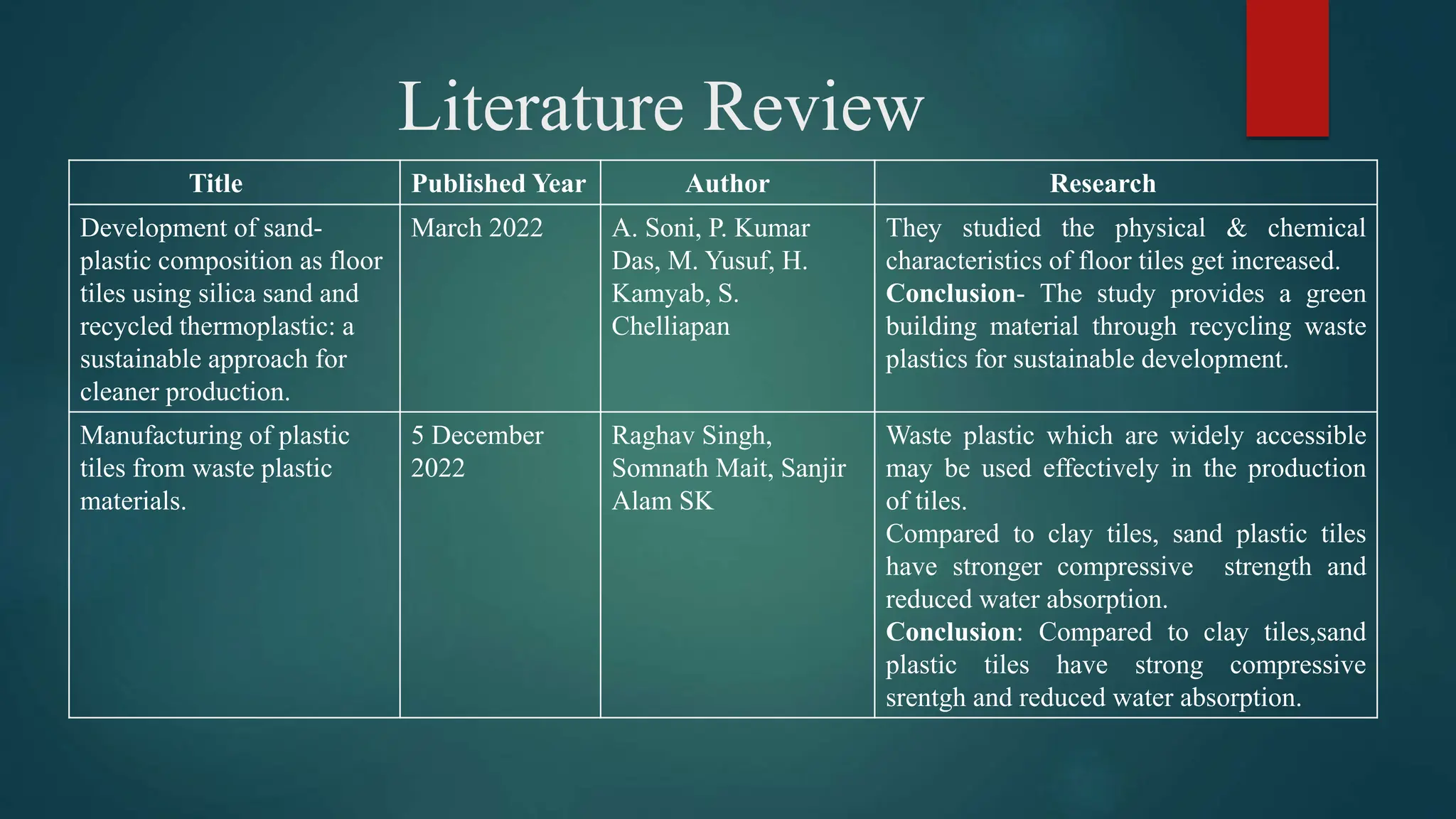

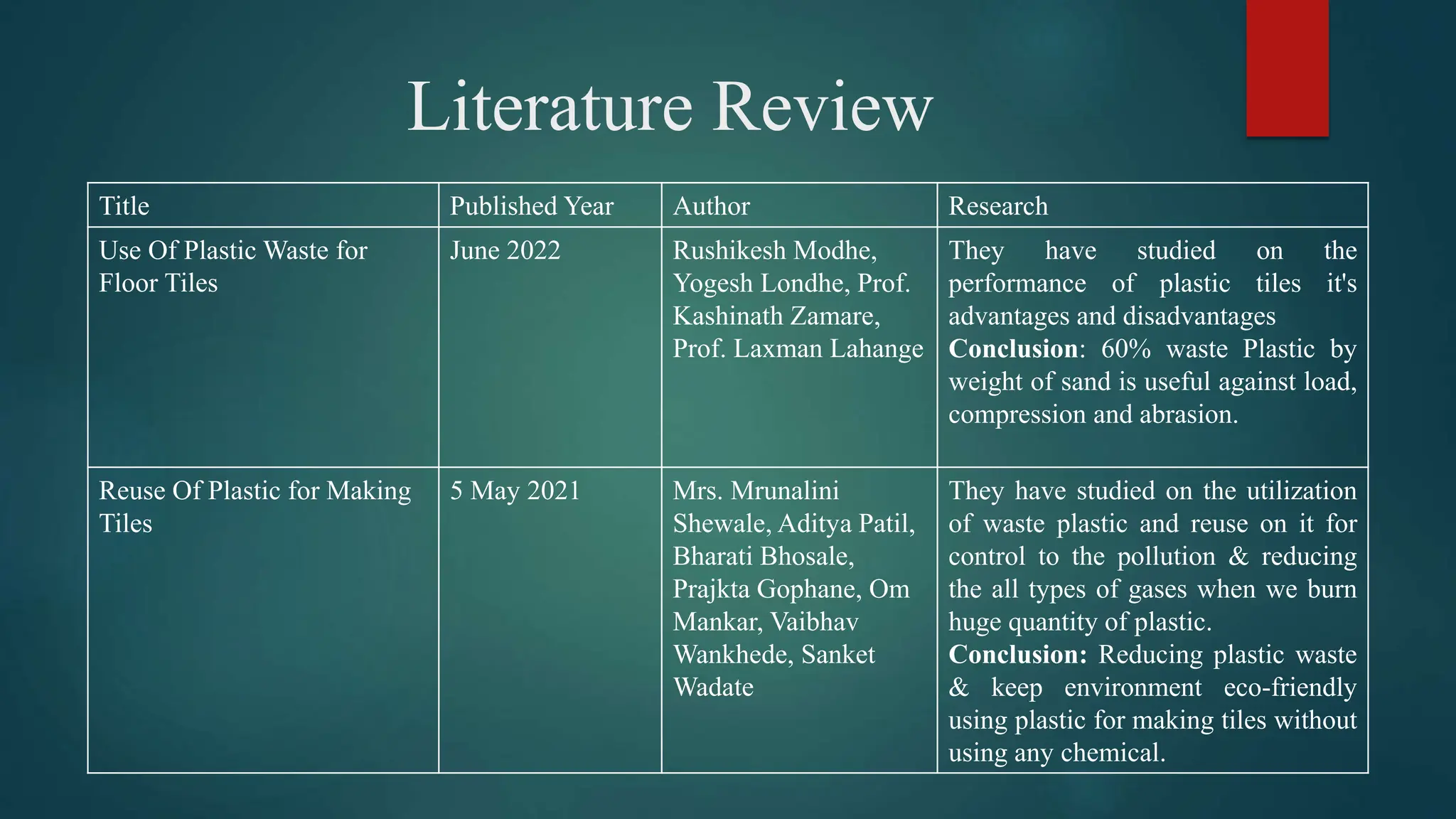

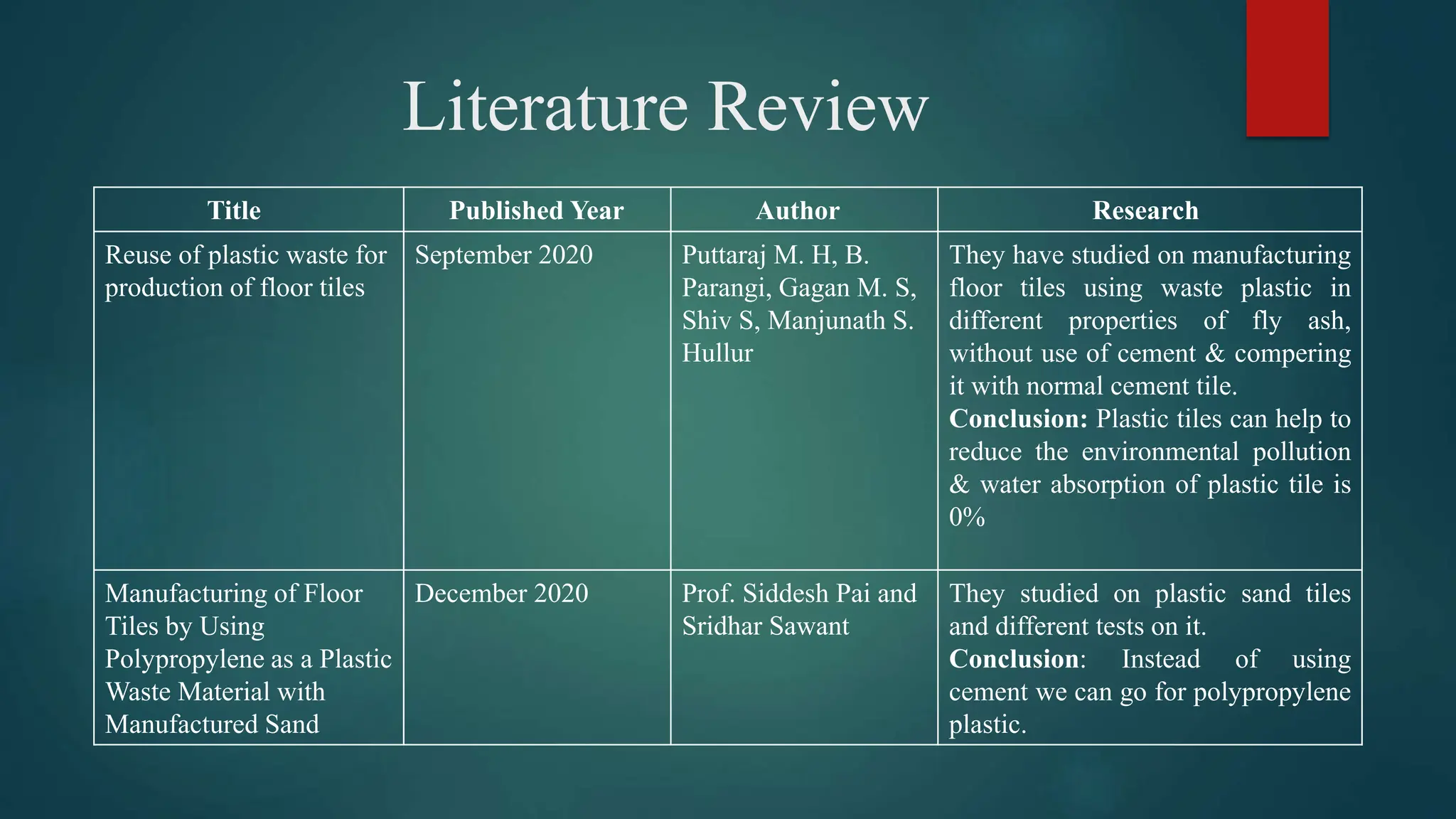

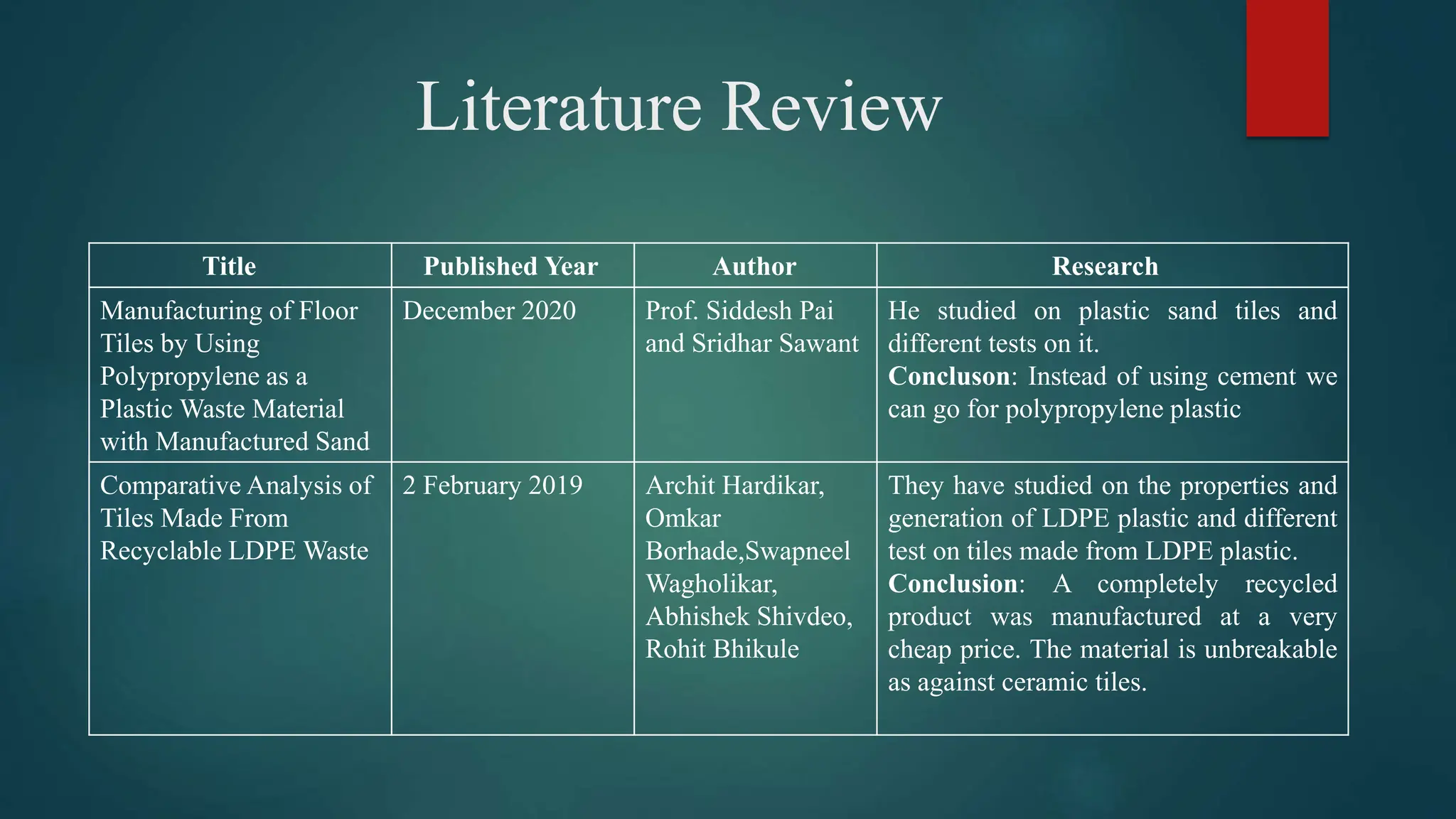

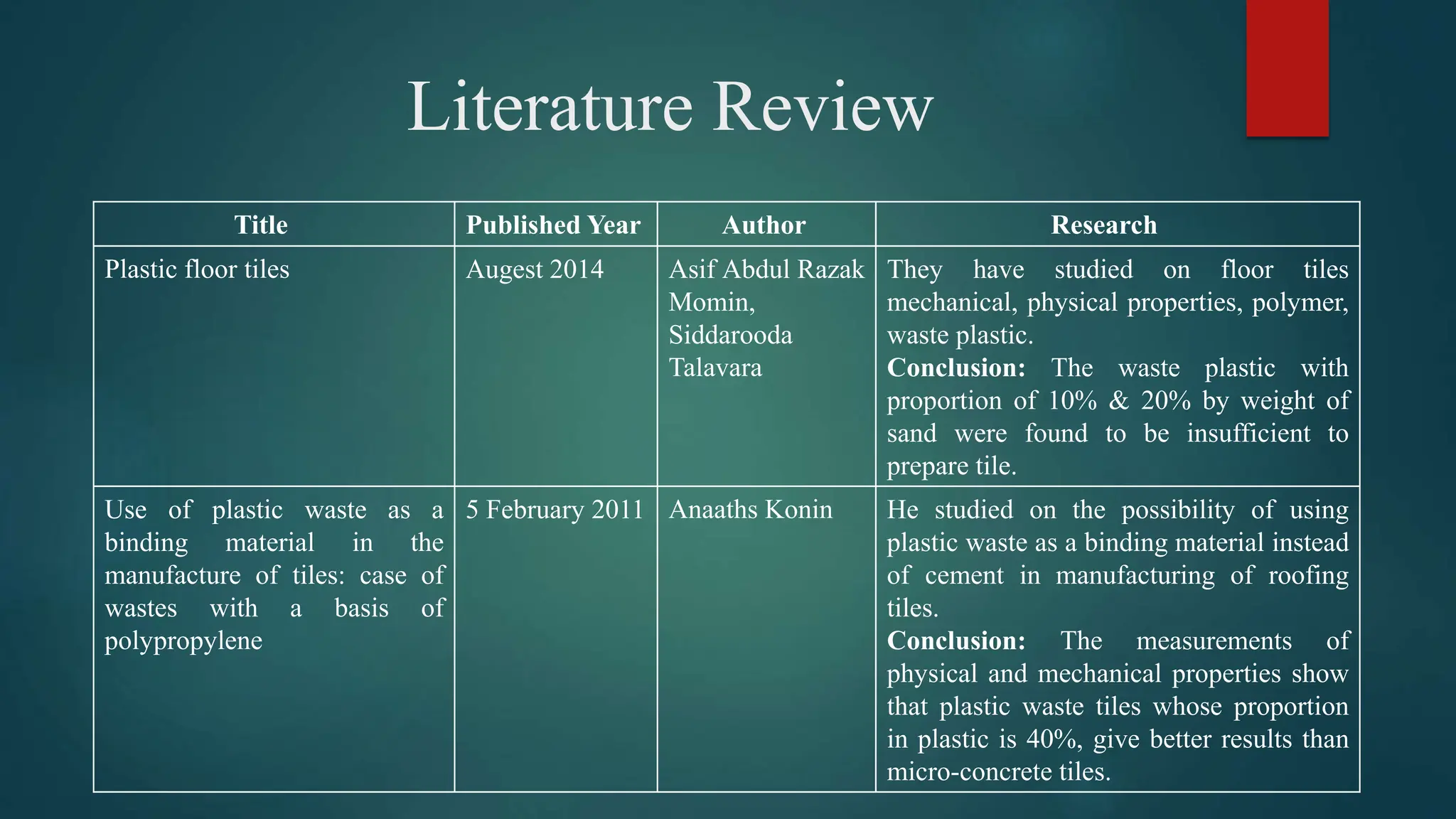

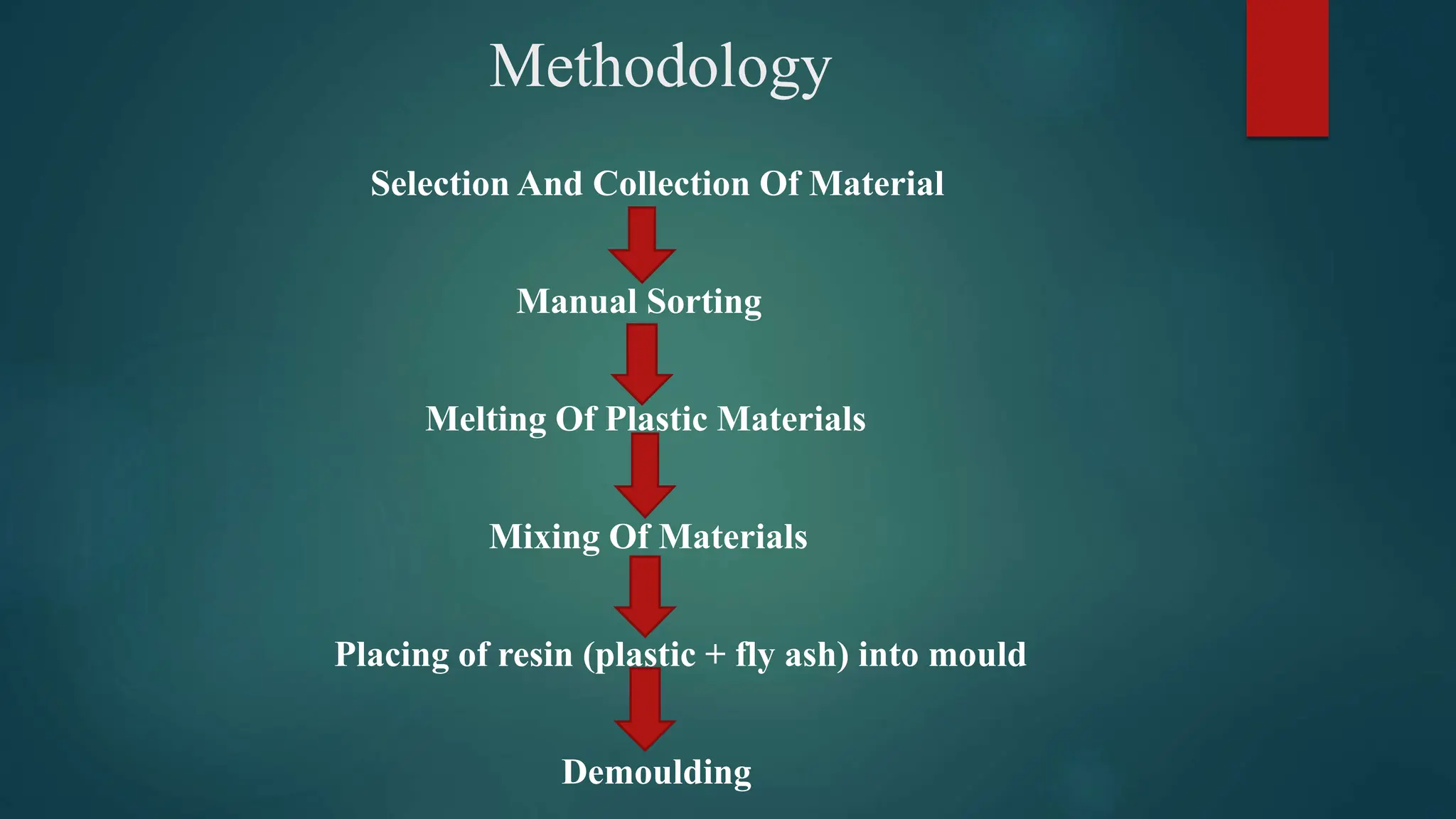

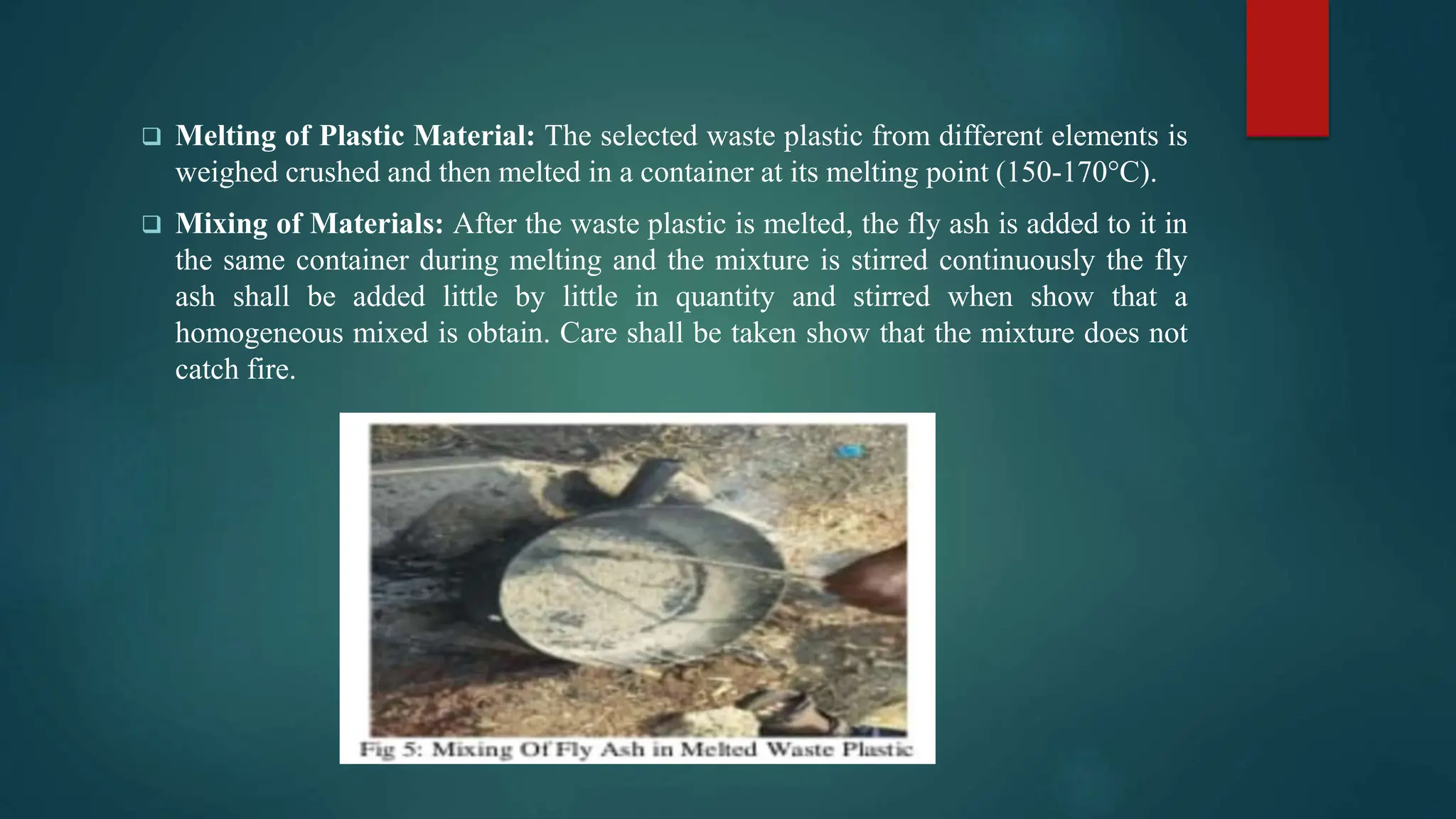

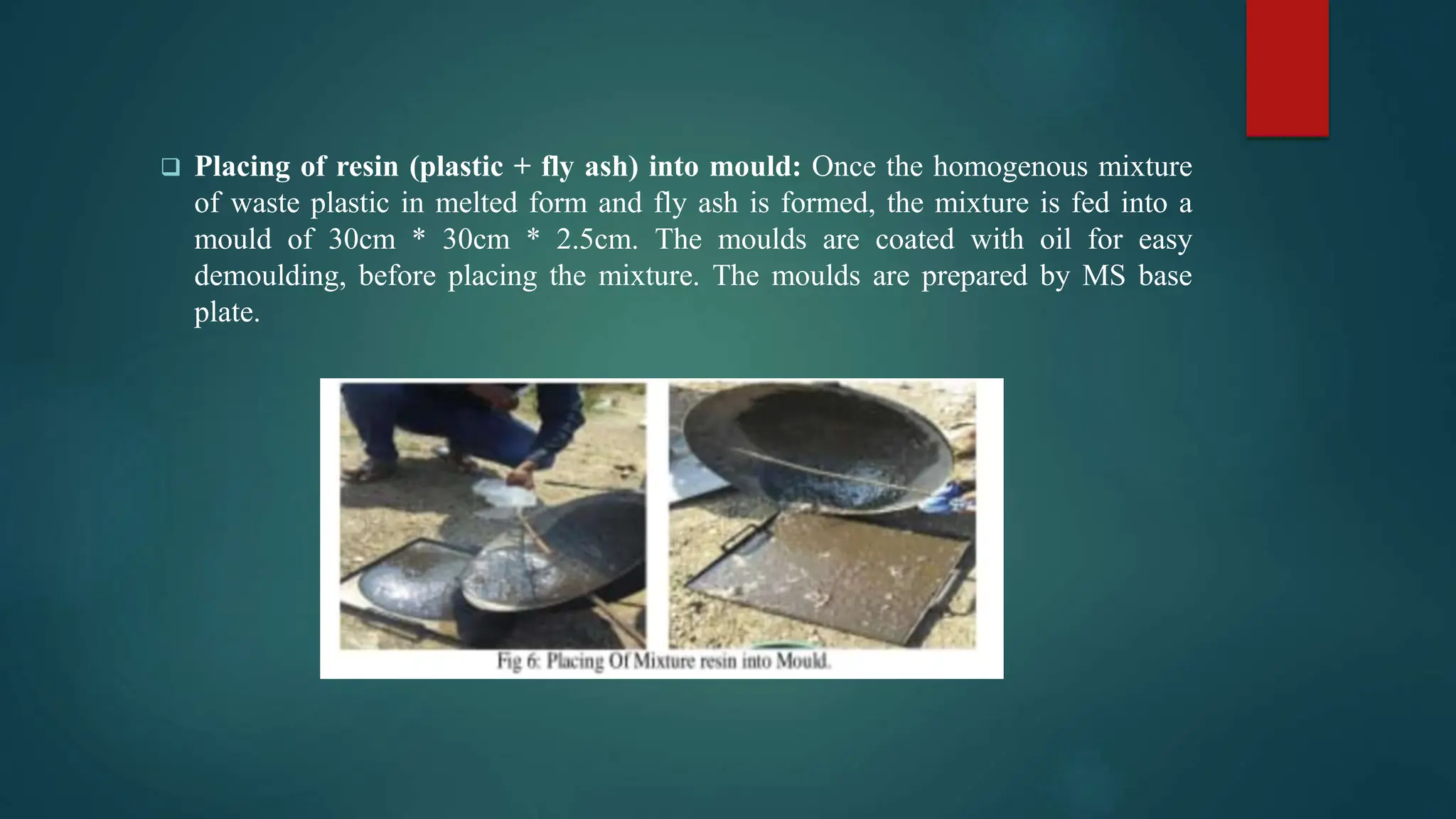

The document presents a project on the manufacturing and performance of fly-ash plastic tiles, emphasizing the environmental benefits of using waste plastic and fly ash in construction. It outlines the introduction, scope of work, problem statement, literature review, methodology, and references associated with the project. The objective is to minimize plastic waste, provide a cost-effective alternative to traditional tiles, and enhance environmental sustainability.