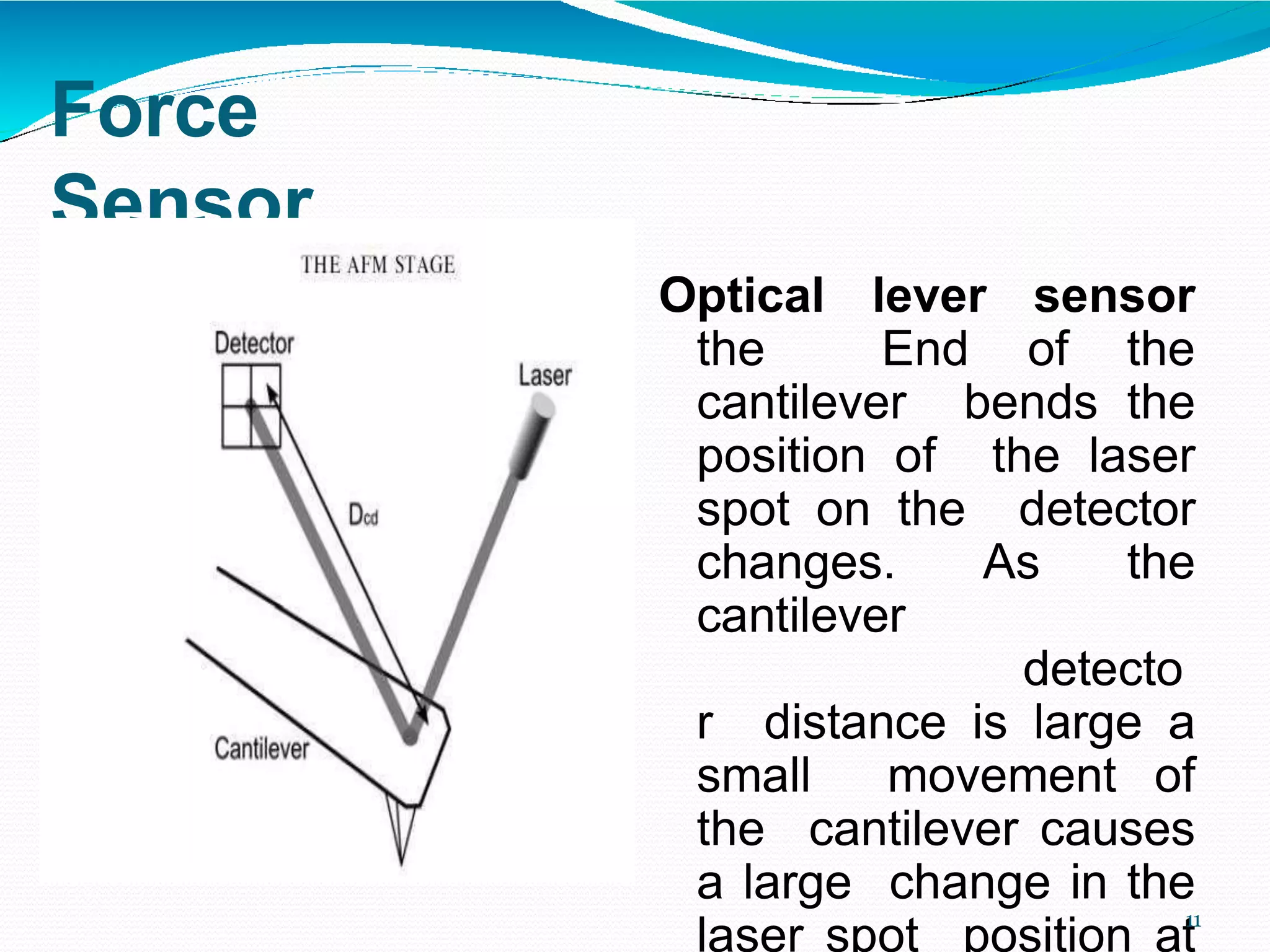

The document summarizes atomic force microscopy (AFM). It describes how AFM works by scanning a probe over a sample surface to build a topography map. The key components of an AFM are a microscope stage, control electronics, and computer. AFM uses a piezoelectric transducer to move the tip over the sample while a force transducer senses the force between them. Different scanning modes are contact, non-contact, and tapping mode. AFM provides high resolution imaging at the single atomic level and can be used to image a variety of biological and material science samples.

![Piezoelectric

transducers

amorphous lead barium

titanate,

Convert electrical potential into

mechanical

PdBaTiO3

motion

. or

lea

d

zirconate titanate, Pb[ZrxTi1–

x]O3,0<x<1

9](https://image.slidesharecdn.com/atomicforcemicroscopy-150320212250-conversion-gate011-220914102018-9798e6bd/75/atomicforcemicroscopy-150320212250-conversion-gate01-1-pptx-9-2048.jpg)