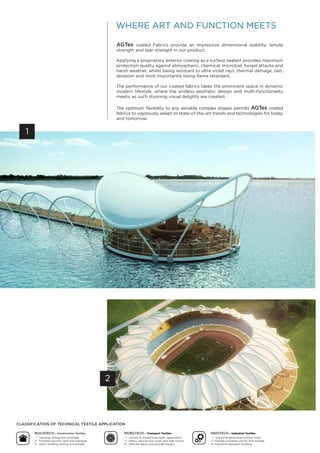

Ateja Grace Texindo specializes in high-performance technical textiles, particularly its Agtex brand composite membranes that offer superior durability, flexibility, and protection against various environmental challenges. The products are designed for a range of applications in architecture, industry, and environmental protection, boasting features like flame retardance, UV resistance, and low maintenance. The company utilizes advanced European coating technology and emphasizes customer testing for suitability of materials for specific applications.