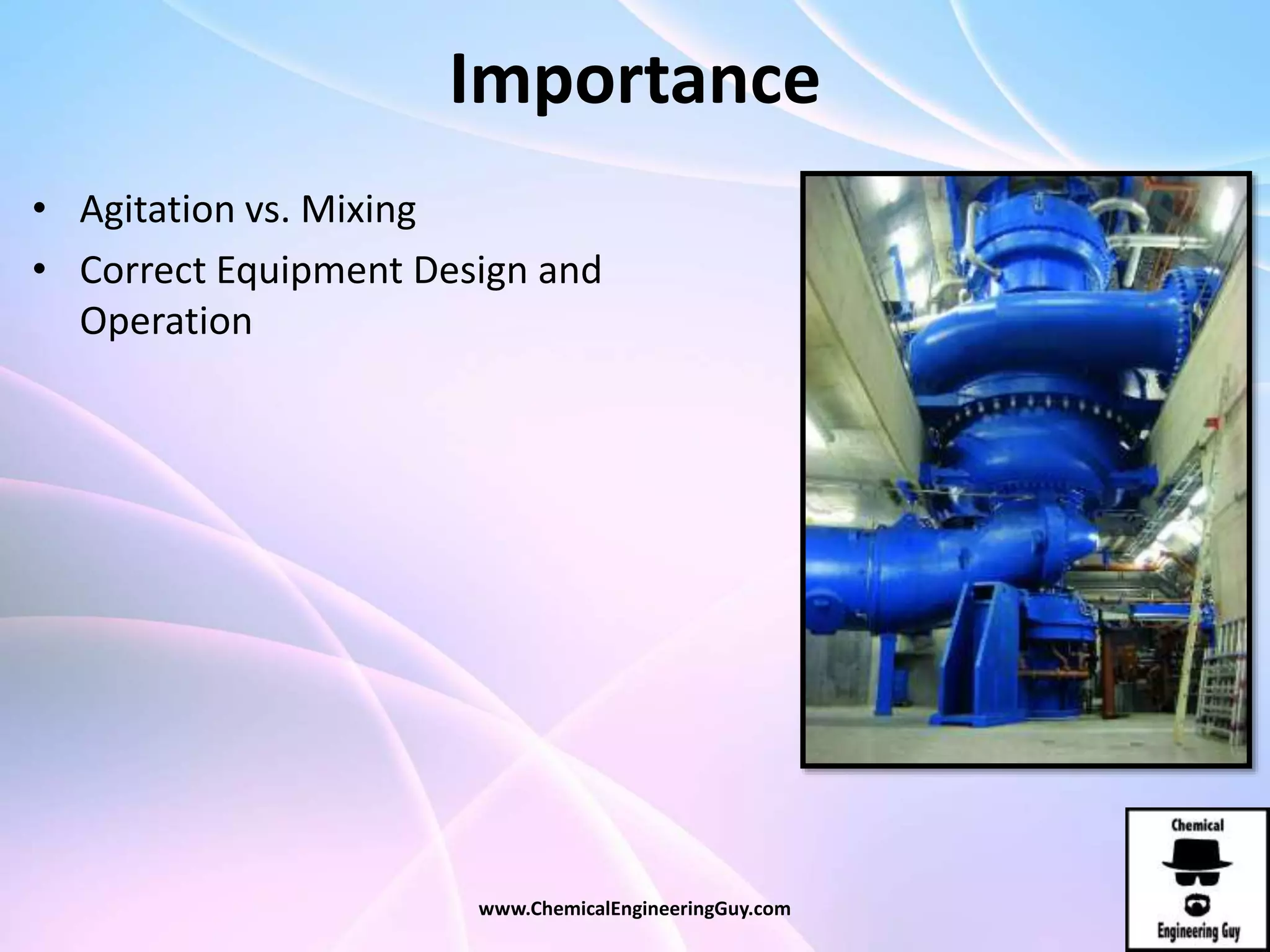

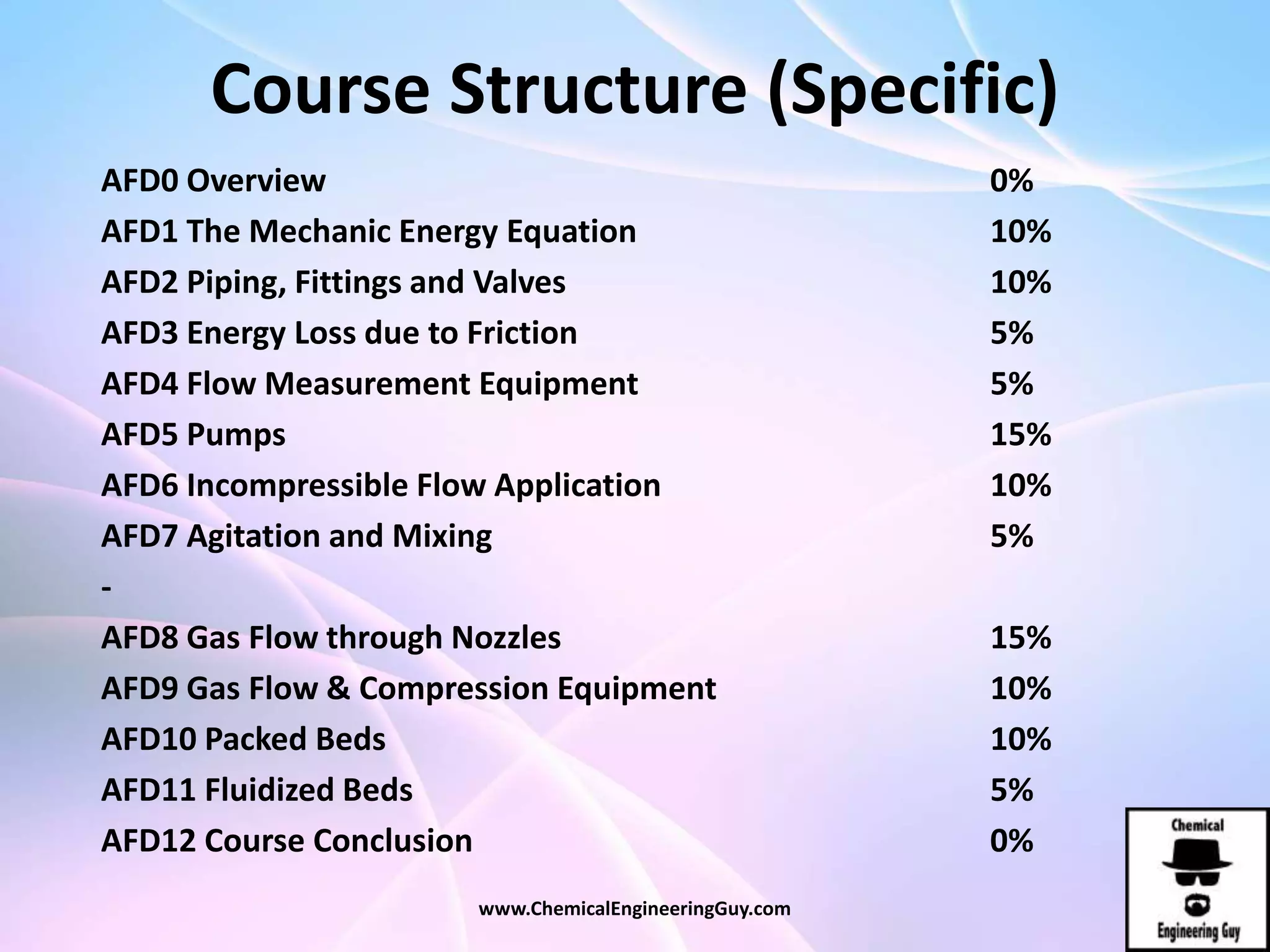

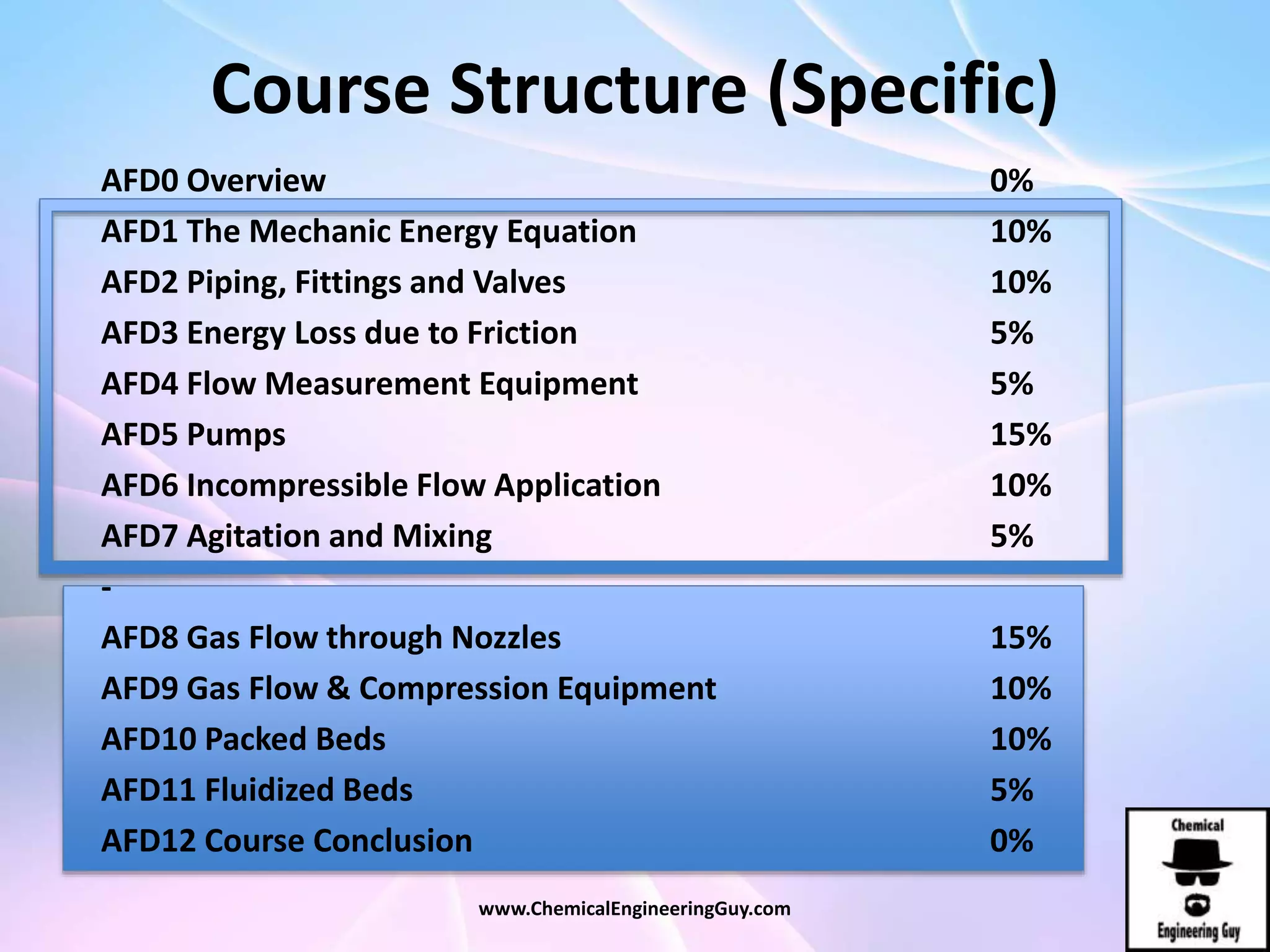

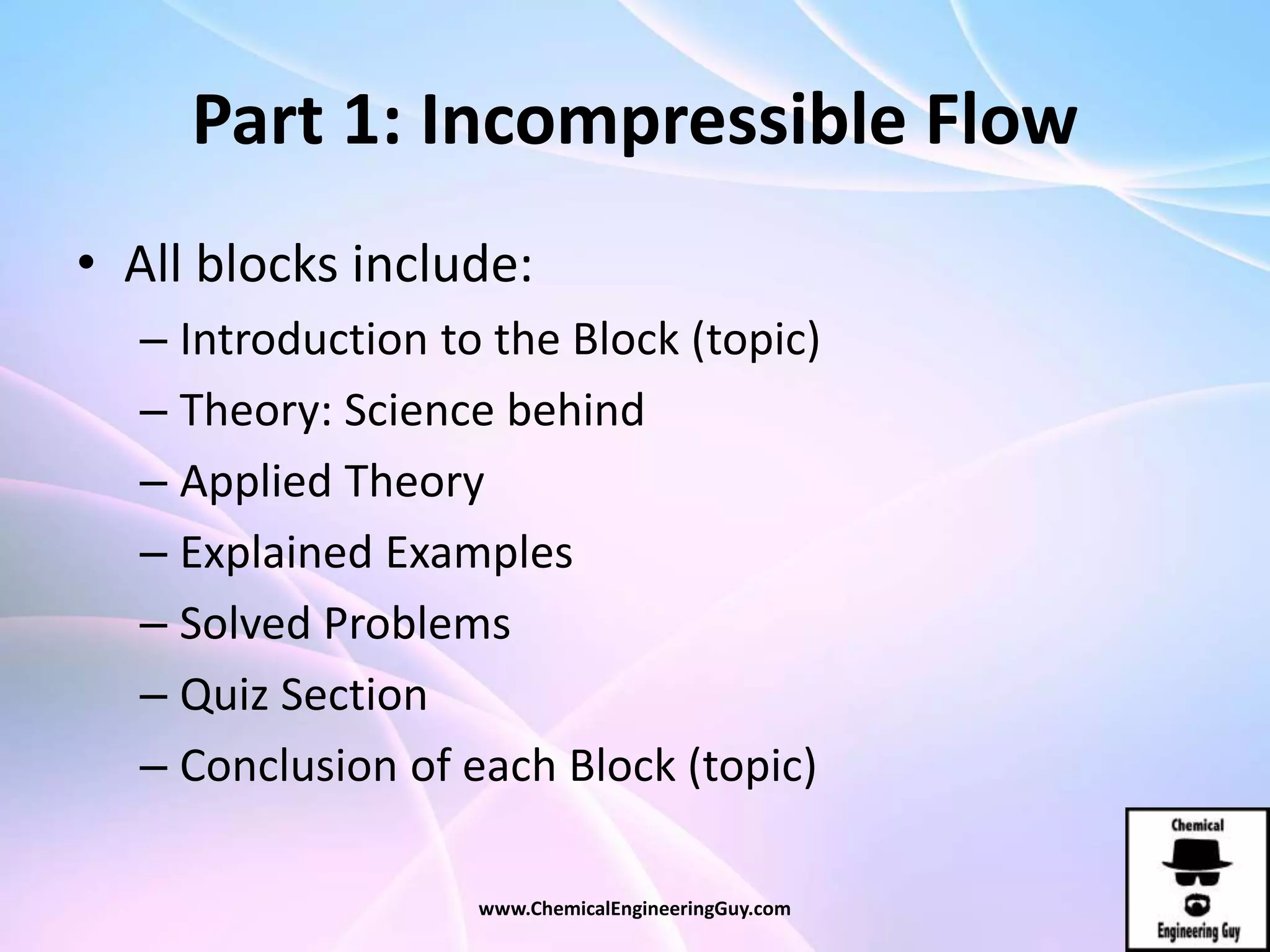

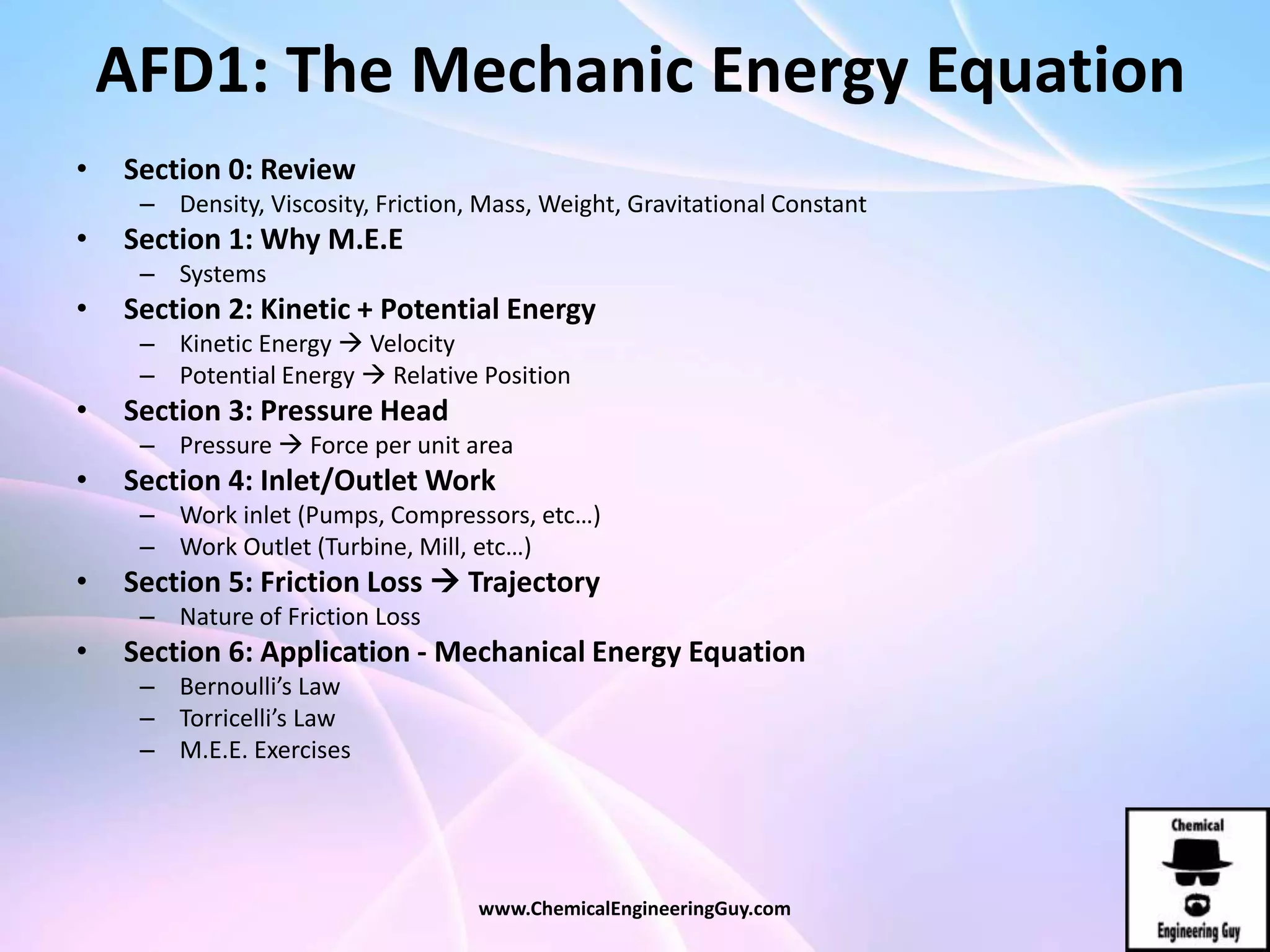

This document provides an overview of a course on applied fluid mechanics for incompressible flow. The course is divided into two parts, with part 1 focusing on incompressible flow (60%) and part 2 on compressible flow (40%). Part 1 covers topics like the mechanic energy equation, piping systems, pumps, and applications. It is designed for engineering students and professionals working with moving fluids of constant density. The document outlines the structure, content, textbooks, and importance of understanding incompressible flow for engineering design and operations.