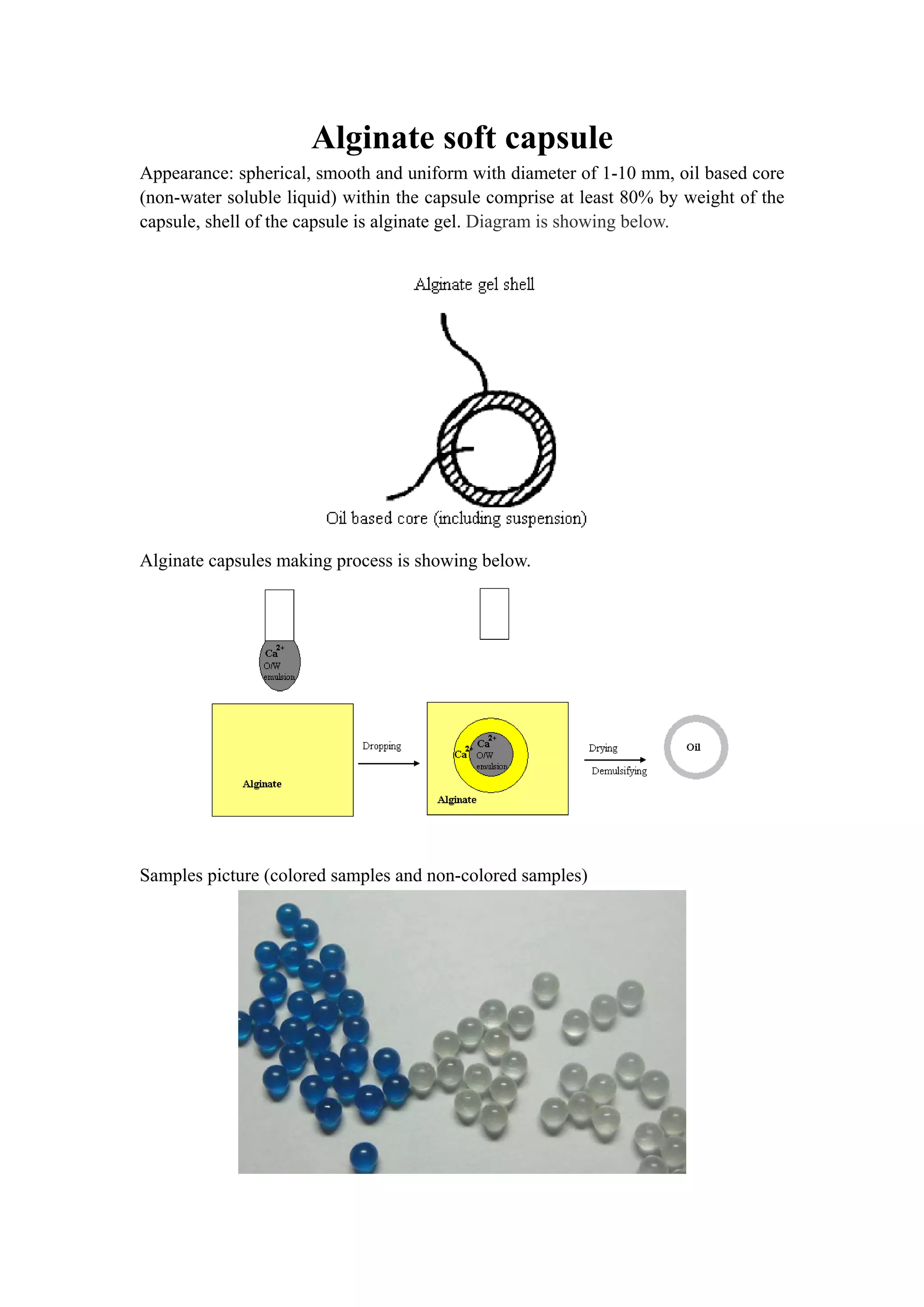

The document describes a patent for alginate soft capsules made from non-animal based materials, offering stability, safety, and cost-effectiveness compared to gelatin soft capsules. The capsules have a spherical shape, release active ingredients in a controlled manner based on various factors, and can be produced efficiently with minimal equipment. Additionally, they are suitable for various applications in pharmaceuticals, food, and industry due to their favorable properties.