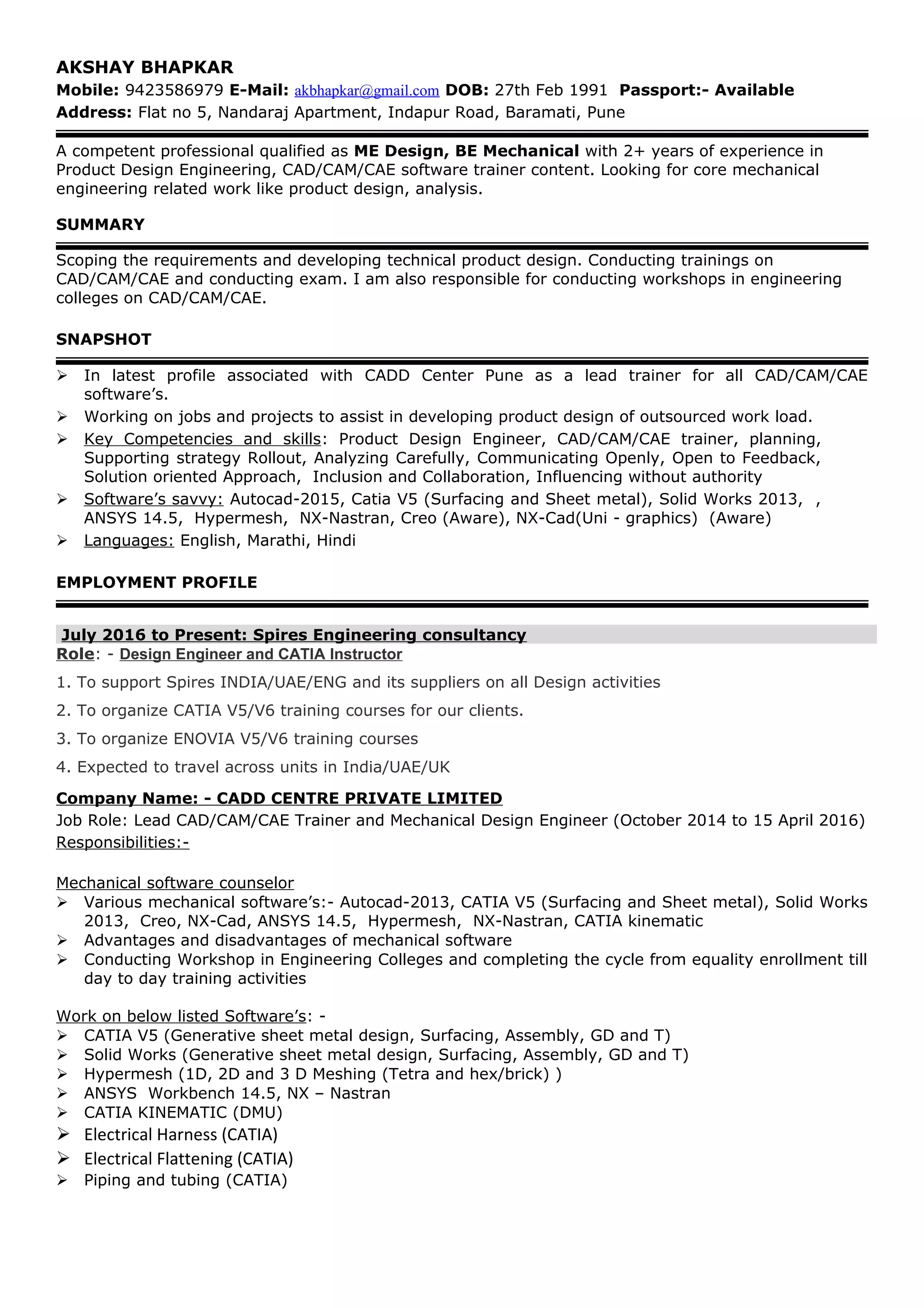

Akshay Bhapkar is a mechanical design engineer with over 2 years of experience in product design and CAD/CAM/CAE software training. Currently a lead trainer at CADD Centre Pune, he conducts workshops and training courses, and has previously worked as a project design engineer with Piaggio Vehicles Pvt. Ltd. He holds a Master's in Engineering (Design) from Pune University and has published work on automotive suspension design.