1) Akash is seeking a position that allows him to fully utilize his potential and adds value through self-development.

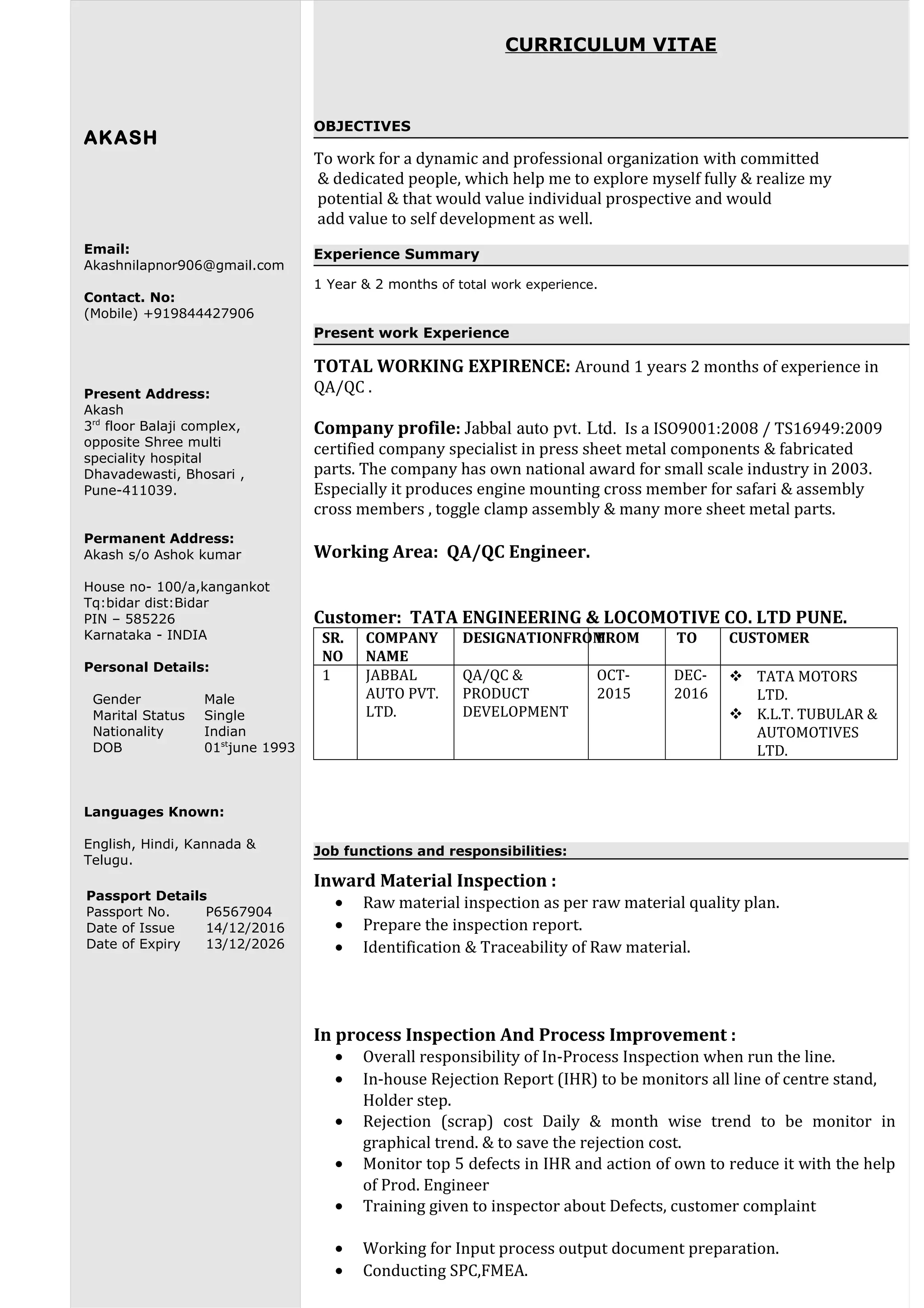

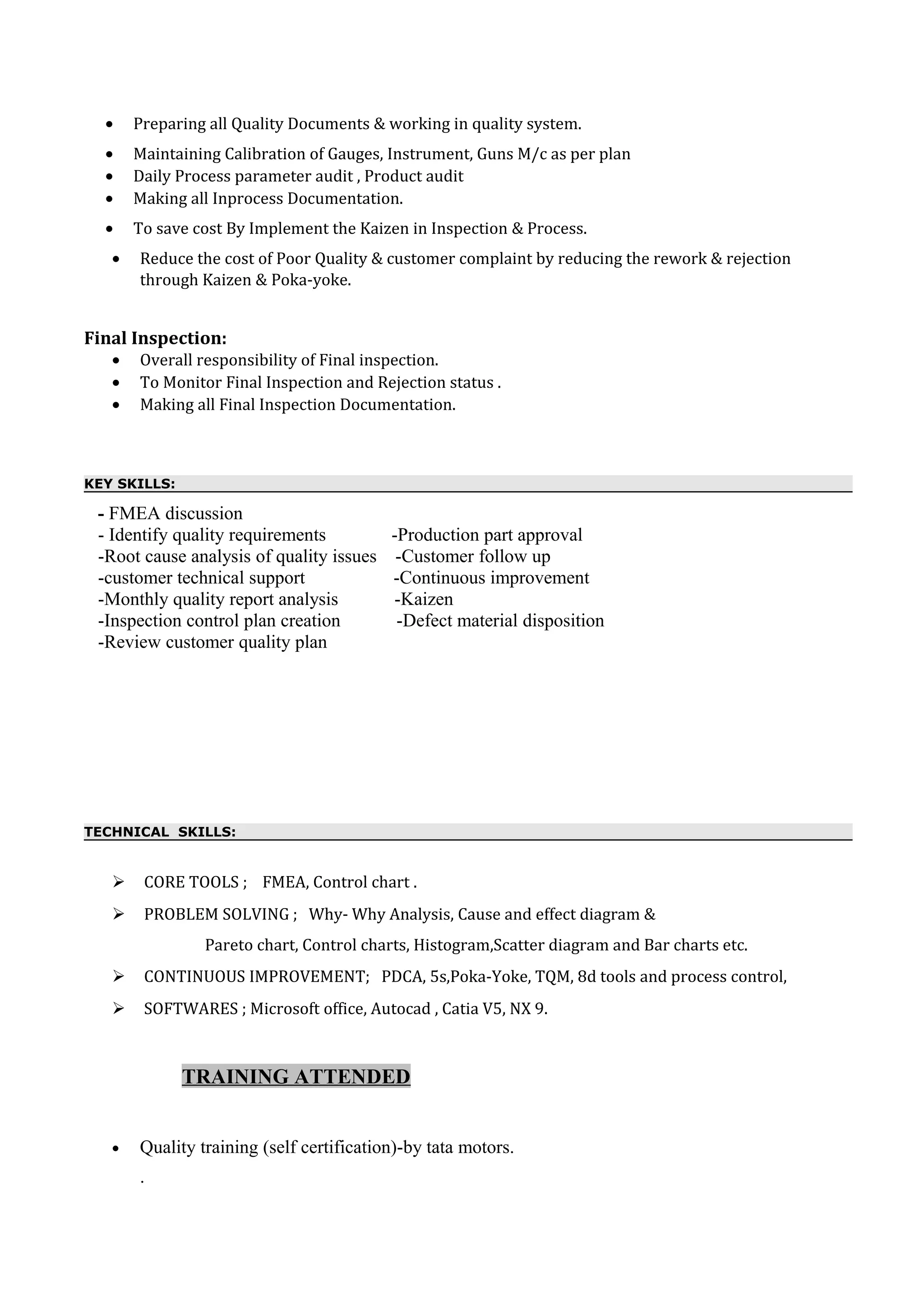

2) He has over 1 year of experience in QA/QC at Jabbal Auto Pvt. Ltd. where he performed inspection, process improvement activities, and quality documentation.

3) His education includes a B.E. in Mechanical Engineering from Guru Nanak Dev College of Engineering in Bidar, India.

![ B.E. In Mechanical Engineering from Guru Nanak Dev Collage Of Engineering Bidar.

Affiliated to V.T.U. Belgaum ( kar.) With (55.06% ).

HSC From Vidya P.U.College Bidar with ( 61.16%).

SSC From Jnana Bharati high school Hallikhed(B) With (70.72%).

Declaration:

I Akash, affirm that the information compiled above is precise and accurate in its entirety to my

knowledge.

[AKASH]

Academic Details](https://image.slidesharecdn.com/2606e670-7da3-4298-915d-e61bdfb90c57-170113120429/75/Akash-Nilapnor-cv-3-2048.jpg)