aisco profile.compressed

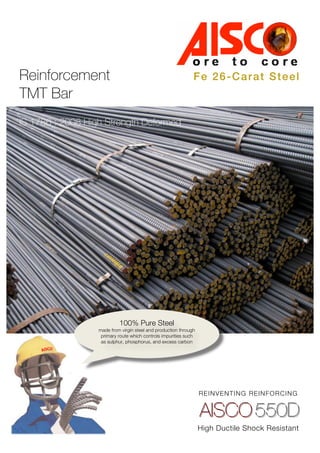

- 1. Reinforcement Fe 26-Carat Steel TMT Bar IS 1786 : 2008 High Strength Deformed AAAIIISSSCCCOOO 555555000DDD 100% Pure Steel made from virgin steel and production through primary route which controls impurities such as sulphur, phosphorus, and excess carbon High Ductile Shock Resistant Rebar REINVENTING REINFORCING

- 2. About AISCO The AISCO Group was established in the year 1990 and since its inception it has developed a strong local & International presence. Strict adherence to quality systems and commitment to continuously improve the performance standards has made AISCO to receive ISO 9001:2000 Certification and deliver products with BIS Certification. AISCO’s Steel Products are produced with the world’s best technology at the fully integrated plant having annual capacity of 2,50,000 MT, located at Rajasthan. The plant has state of the art technology and strict quality control to produce finest quality of Steel Products across the entire spectrum of the value chain from basic minerals Iron Ore, from Sponge Iron to Billets & finally to TMT Bars. The Directors of AISCO are India’s best team of highly competent & experienced professionals, comprising of Engineers from India’s prestigious Institutes and experienced professionals from India’s Steel Giant. The continuous strive for excellence, pioneering spirit; clear vision for future & commitment to achieve has made AISCO’s team one of the most innovative, productive and empowered workforces in Steel Industry. Ore to Core With the experience & expertise gathered, AISCO now introduces top quality Steel Bars using its basic concept of Ore to Core at manufacturing facilities which include Induction Furnace LRF and Continuous Casting Billet Machine (CCBM), Reheating Furnace & Automatic Rolling Mill for manufacturing Billet & TMT Bars all under one roof, where top quality Sponge Iron is sourced to cast into billets in CCBM and these billets are then rolled into TMT Bars with ferrite-pearlite core like other main producers. Raw Material The AISCO team follows the basic philosophy of “Quality Begins with Me”. The Quality Checks begin right from the stage of procurement of Raw Material like Sponge Iron & Ferro Alloys etc. and are followed till the final product is received. AISCO’s infrastructure is fully equipped to ensure quality checks at every stage. AISCO has a well- equipped laboratory for all kinds of quality tests, including the latest Spectrometer for the most accurate chemical analysis. AISCO using direct reduced iron (DRI) for the production of quality castings. Sponge Iron due to its inherent plus points like virgin nature, low sulphur and phosphorous contents and consistency of composition, procured from Primary and Large Steel Producers with good strength and high metallic contents melt in the furnace. Each heat 3 samples are drawn from beginning, middle and end of teeming of ladle analysis and adding the alloys as per desired chemical composition. The Melton Steel is tapped into a ladle and taken to the continuous casting machine for finished rolling. Unique chemistry AISCO TMT bars are produced as per specifications mentioned IS: 1786. However, carbon level is restricted to much lower than the specification, resulting in excellent ductility, bendability and weldability. Constituent Maximum Fe 500 Fe 500D Fe 550 Fe 550D Fe 600 Carbon % 0.30 0.25 0.30 0.25 0.30 Sulphur % 0.055 0.040 0.055 0.040 0.040 Phosphorous % 0.055 0.040 0.050 0.040 0.040 Sulphur & Phosphorus % 0.105 0.075 0.100 0.075 0.075

- 3. AISCO Rebar’s Uniform Rib Pattern AISCO TMT has a unique rib pattern in terms of greater rib depth & closer rib spacing. Its ribs are made using Computer Controlled CNC Notch Cutting Machine. This ensures uniform rib pattern for 100% of the bars, which allows uniformly strong bonding with concrete for the whole structure contrary to the ordinary rebar where ribs are cut using the manual method and have non-uniform rib pattern and give weaker bonding throughout the structure. Thermo Mechanical Treatment Process for Reinforcement Bars The use of Thermo Mechanical Treatment process has not only helped produce re-bars of high yield strength but also having superior ductility, weld-ability, bend-ability, better corrosion resistance and thermal resistance creating a revolution in re-enforcement engineering. AISCO’s High quality Reinforcement Bars are produced at most advanced, fully automatic, high-speed rolling mill through “Quenching and Tempering Process” with international technology. Quenching is the first stage where after leaving the final roll the bar enters the fully automatic and computerized quenching box, where water is sprayed on the surface of rebar to bring down the temperature of the surface of the bar at desired temperature. It hardens the outer surface called “Martensite”. Self-Tempering is the next stage. The bar leaves the quenching box with the temperature of the core being higher than that of the surface. This allows heat to flow from the core of surface, resulting in tempering of the surface. This gives a Strong and Tough outer surface called “Tempered Martensite”. Atmospheric Cooling is the final stage. Cooling of rebar takes place when it reaches the walking cooling bed (automatic mechanised), finally turning the austenitic core into ferrite-pearlite core, which is ductile. The process of “Quenching & Tempering” thus results in an outer rim at the surface, which is tough and strong, and a ductile center giving the rebar a combination of strength and ductility. Safe and strong AISCO TMT possesses a combination of strength and enhanced ductility that is far in excess of the minimum limits specified in the standard IS 1786. The normal yield strength for AISCO TMT is 550N/mm2 against 500N/mm2 as specified in BIS standards, which is the value engineer’s use for design. Moreover, the ductility as measured by elongation is 18% minimum against the standard value of 12% minimum. These superior values of strength and ductility are a guarantee of higher levels of safety. Mechanical Properties Unit Fe 500 Fe 500D Fe 550 Fe 550D Fe 600 Yield Stress, Min N/mm2 500 500 550 550 600 Tensile strength, Min N/mm2 545 565 585 600 660 Elongation, Min % 12 16 10.0 14.5 10.0 Product Range & Standards AISCO TMT Rebars are available in the following sizes 6, 8, 10, 12, 16, 20, 25, 28, 32, 36 & 40 mm. AISCO TMT rebars are comparable to India, America, British and Australian standards. Saving in Steel by Dimensional tolerance Each AISCO rebar is rolled as per IS 1786:2008 mass tolerance controlled between mines to Zero, which reduces overload and the quantity of steel consumed by 4 to 8%. Seismic Resistant Properties The technical team of AISCO has introduced AISCO TMT Bars with “Uniform Elongation with Enhanced Ductility” which gives strong resistance to earthquakes. Bundling & Packing Each AISCO rebar is cut in a fixed length of 12 meters to ensure better planning & less wastage during fabrication and bundles with fixed number of pieces per bundle.

- 4. Core Values of AISCO’S TMT BARS ü ISO- International Quality Certificate ü BIS Certificate IS 1786:2008 for HSD ü Integrated Steel Plant (Ore to Core) ü Sponge Iron, Raw Material (made from virgin Iron) ü Primary Route for Production ü Controlled Chemistry (low C, S, & P) ü Billets rolled rebar ü Computerised Notch Cutting Ribs ü Quenching (Intl. Tech.) ü Uniform air-cool of TMT Bars with Automatic Cooling Bed ü Up to Fe 600 grade for High Strength ü ‘D’ grade for enhanced Elongation ü Earth Quake Resistance ü High Fire Resistance ü Corrosion Resistance ü More Bendability ü Better Weldability ü 8mm to 40mm Dias product range ü 12 meter Fixed Length ü Bundles of 0.8Mt to 4.0MT ü Thickness within BIS limit (minus to zero) ü F.O.R. Site delivery in straight length ü Price remain constant for one month ü Saving: Due to controlled thickness Due to 12 meter fixed length Due to price constant for month Due to 500 & 550 grades, 20% Due to sheared cut both side Due to no need to re-test at site AISCO Metal (P) Limited A Fully Integrated Steel Plant Anatpura, Sikar Road, Balekhan, National Highway 11 Near Chomu, Rajasthan 303712 Email: aiscogroup@outlook.com Skype: aiscogroup Web: www.aisco.in