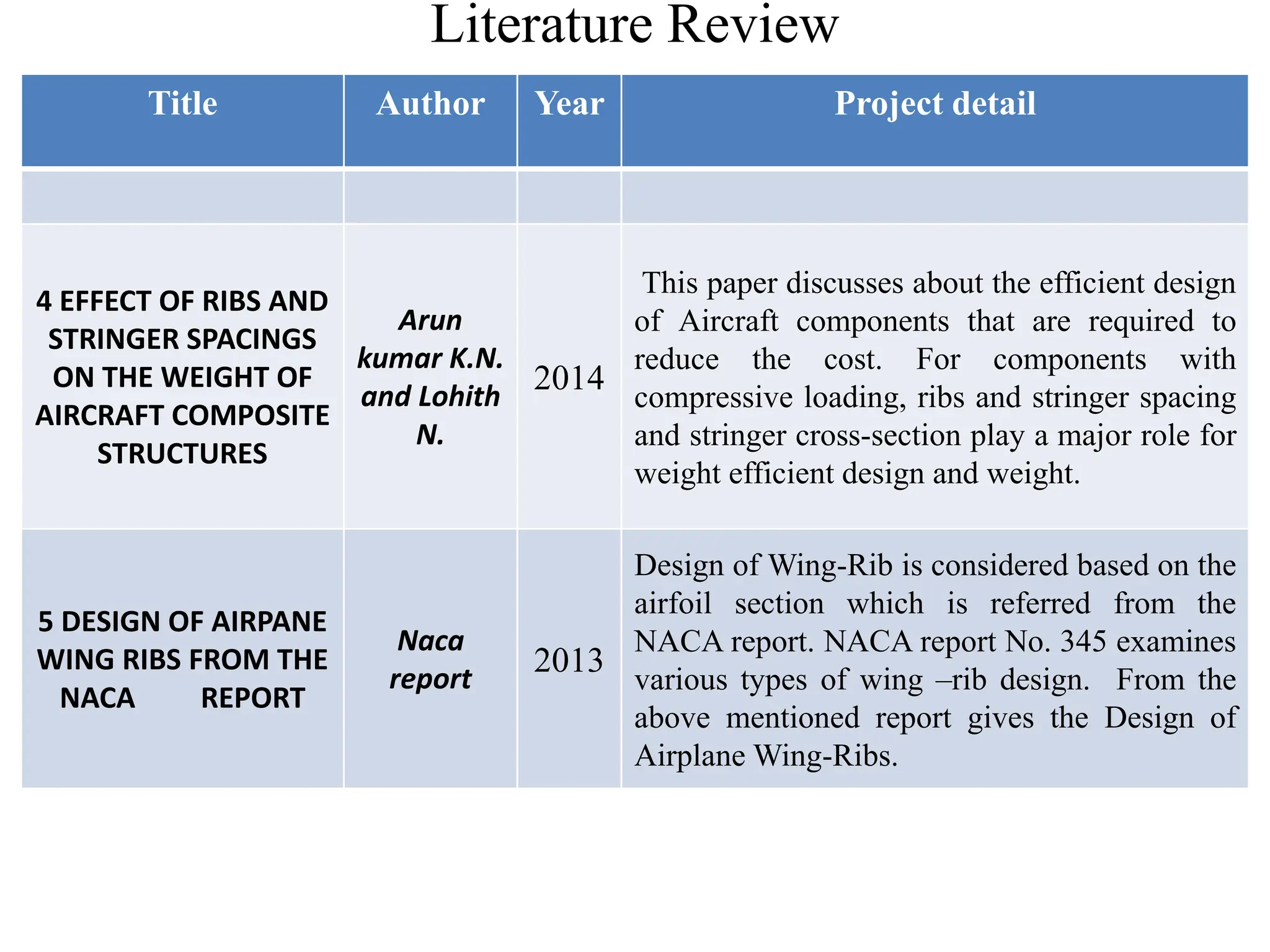

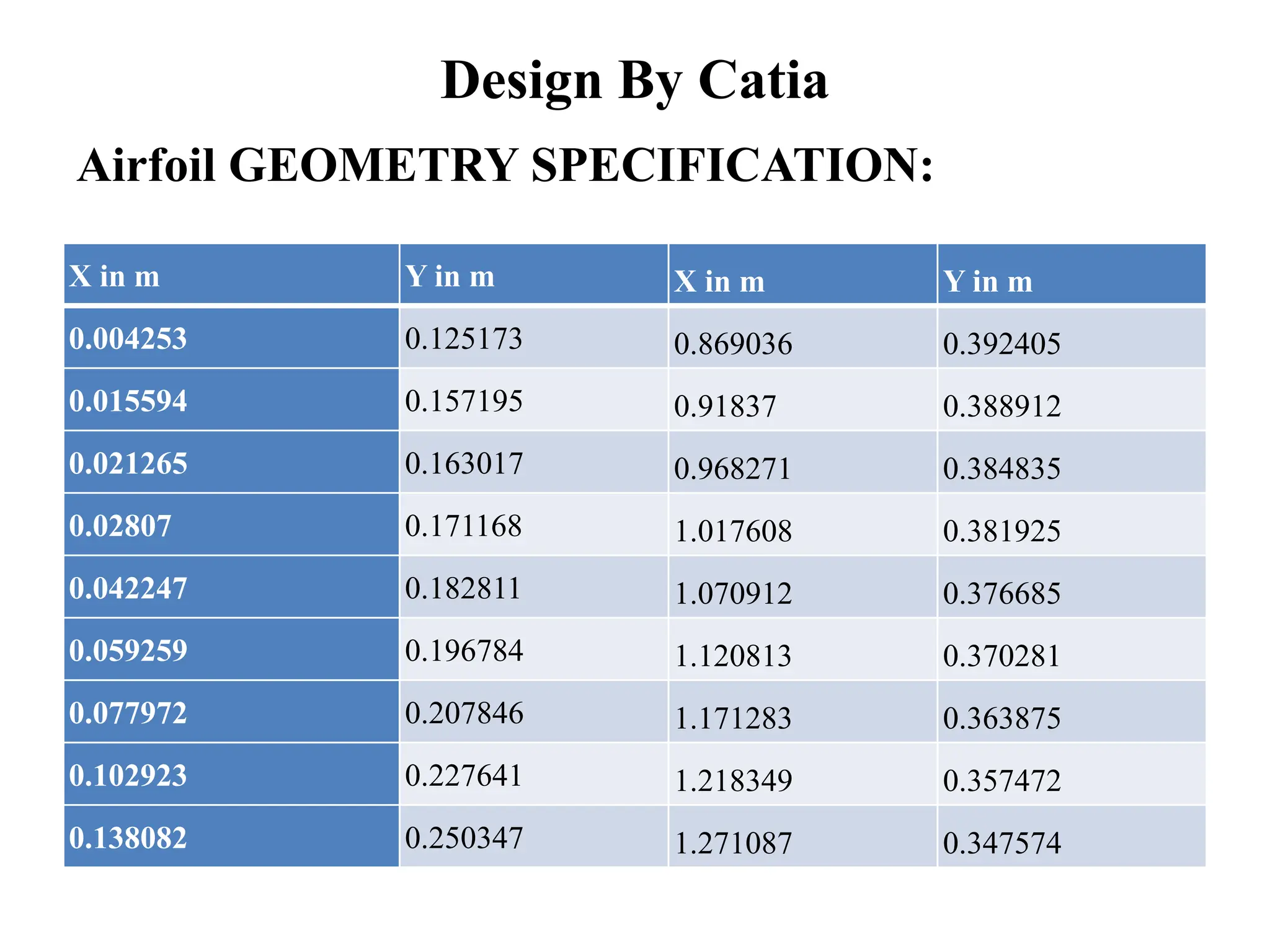

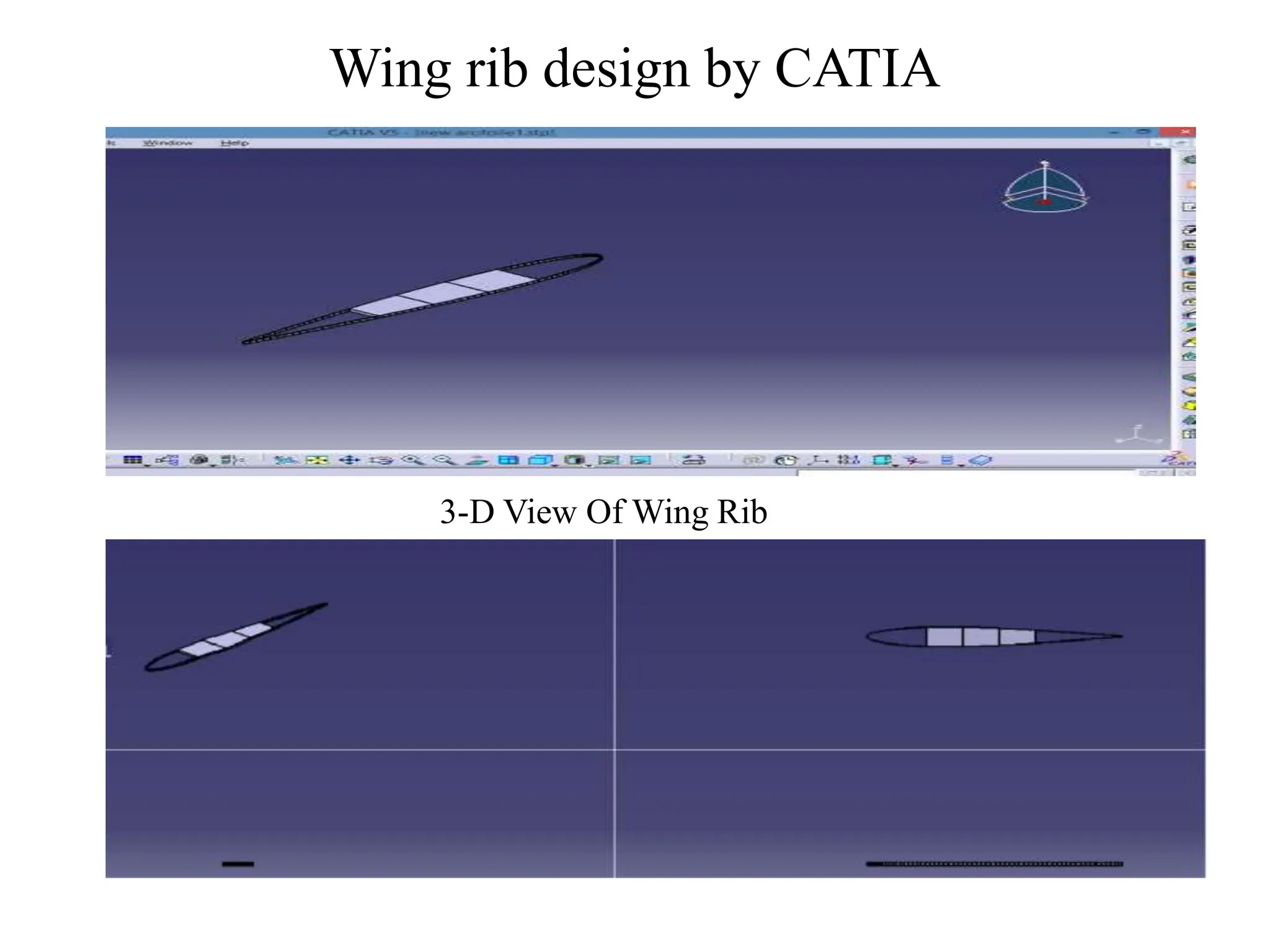

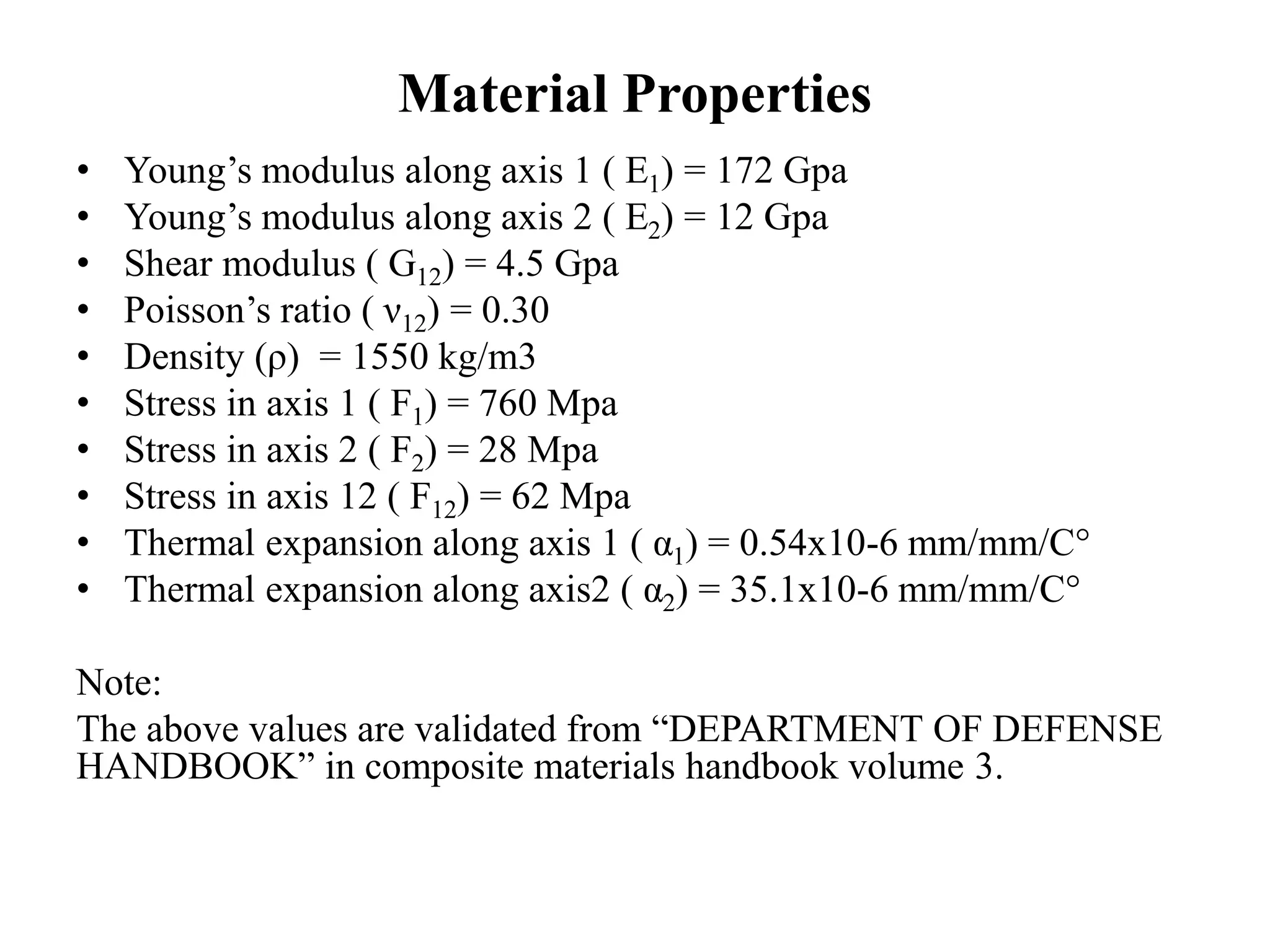

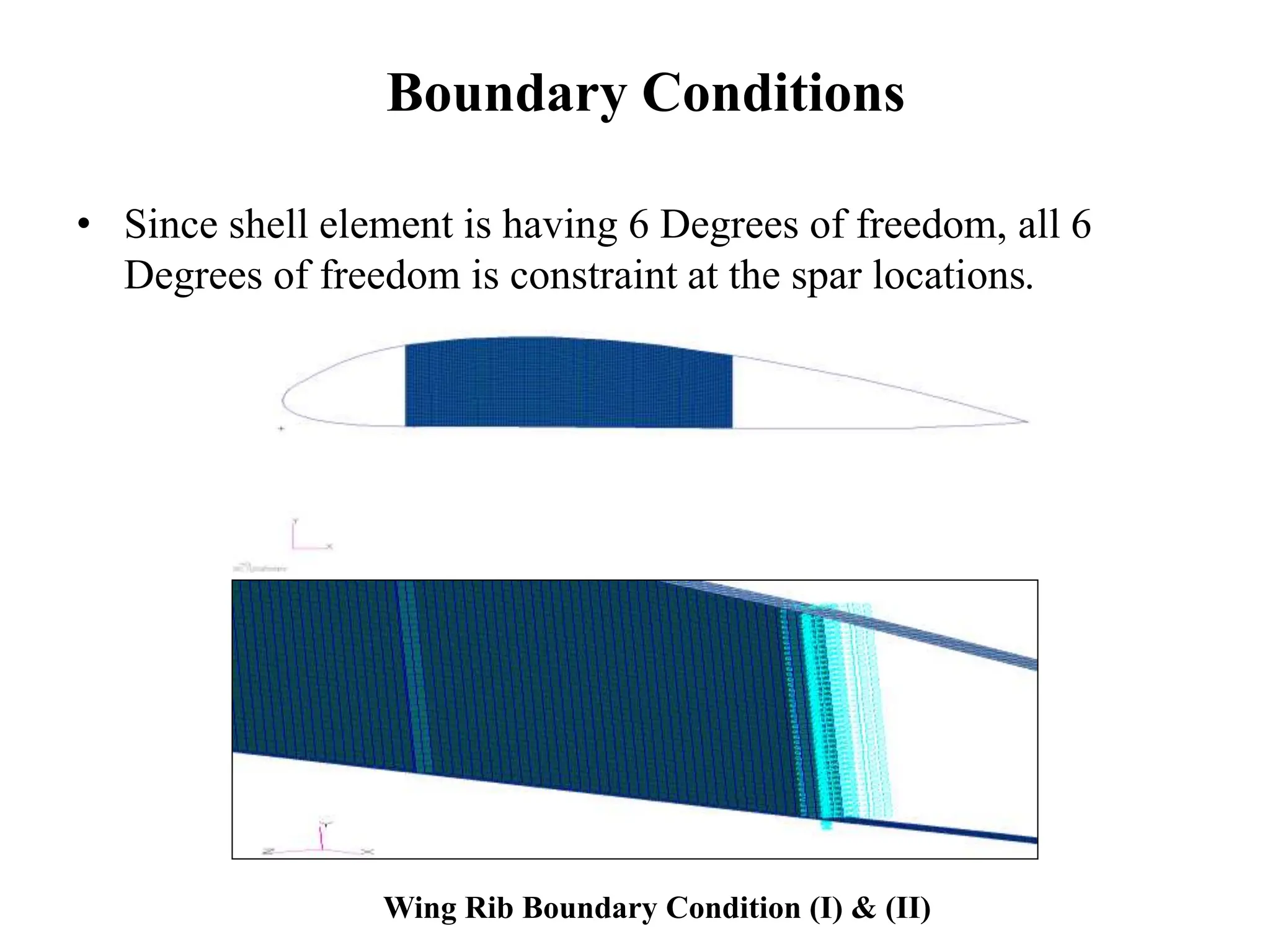

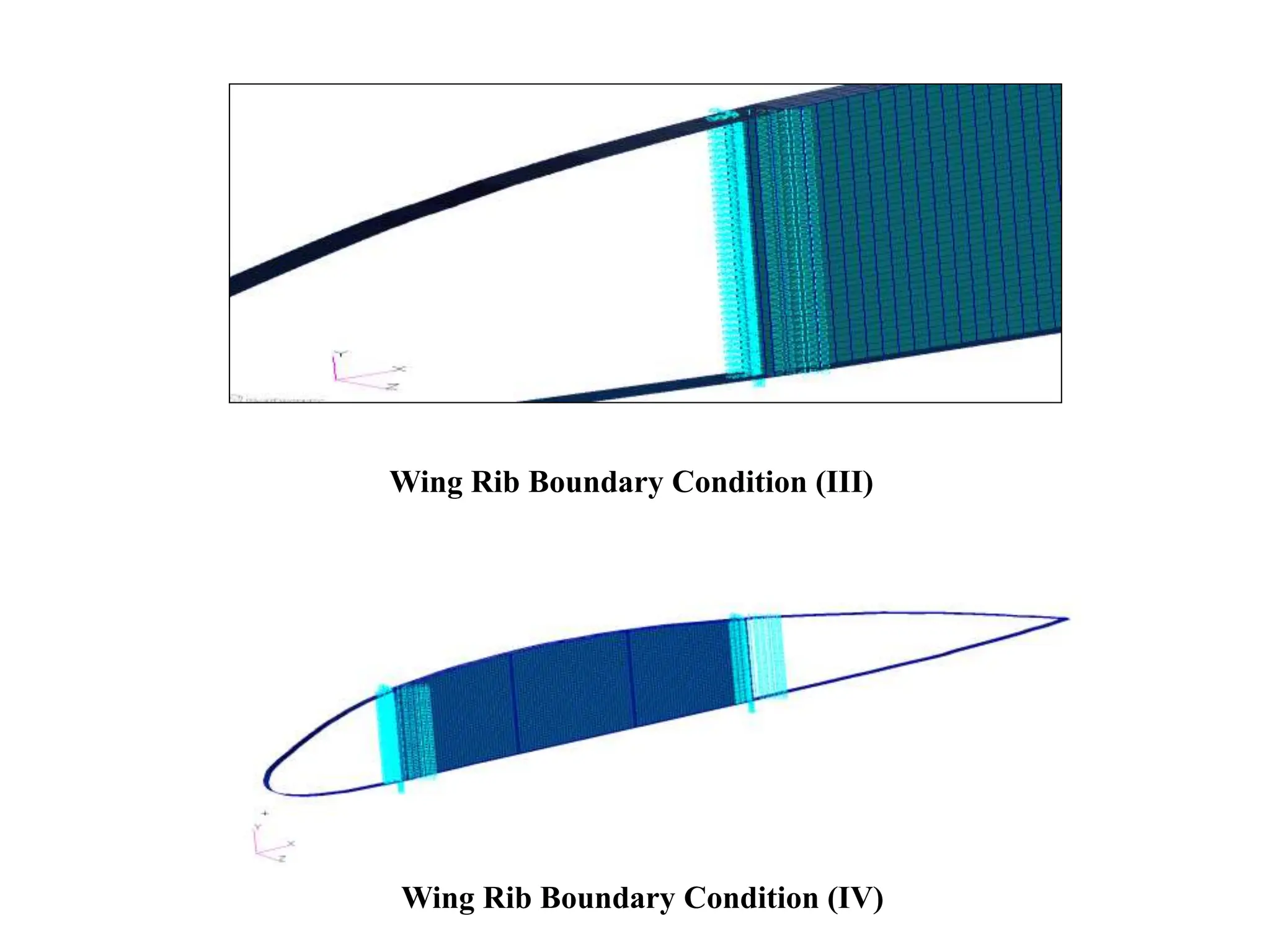

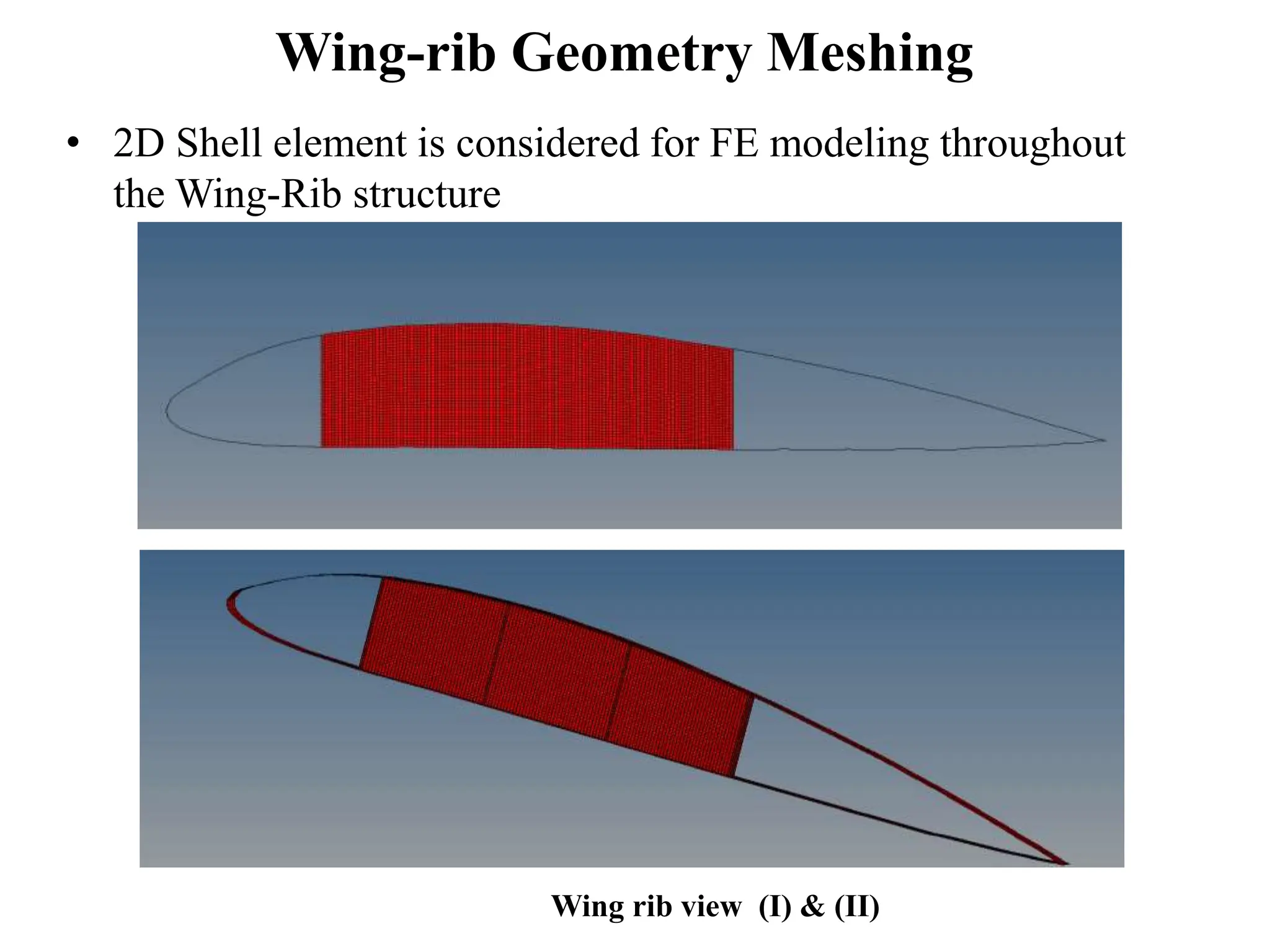

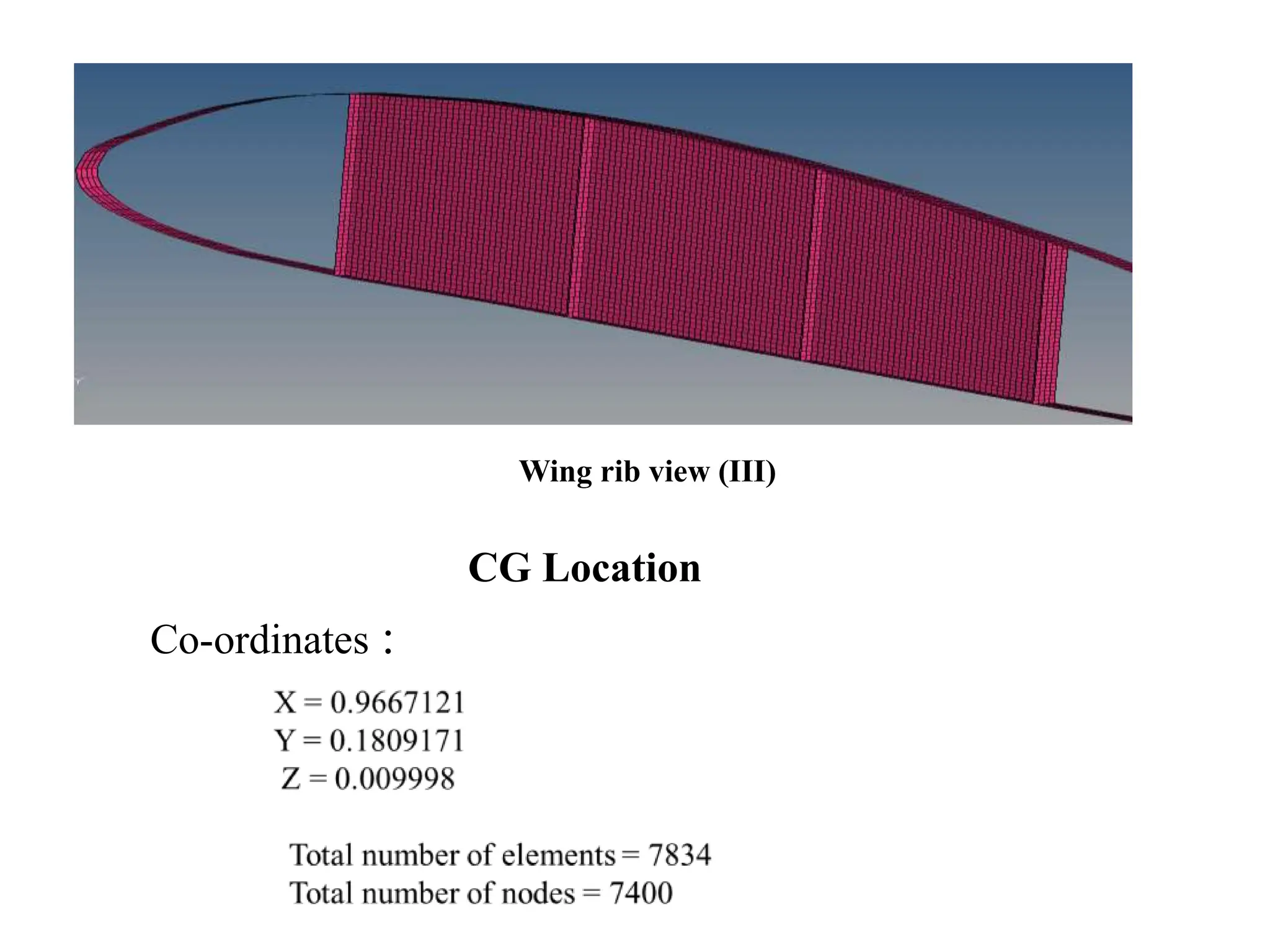

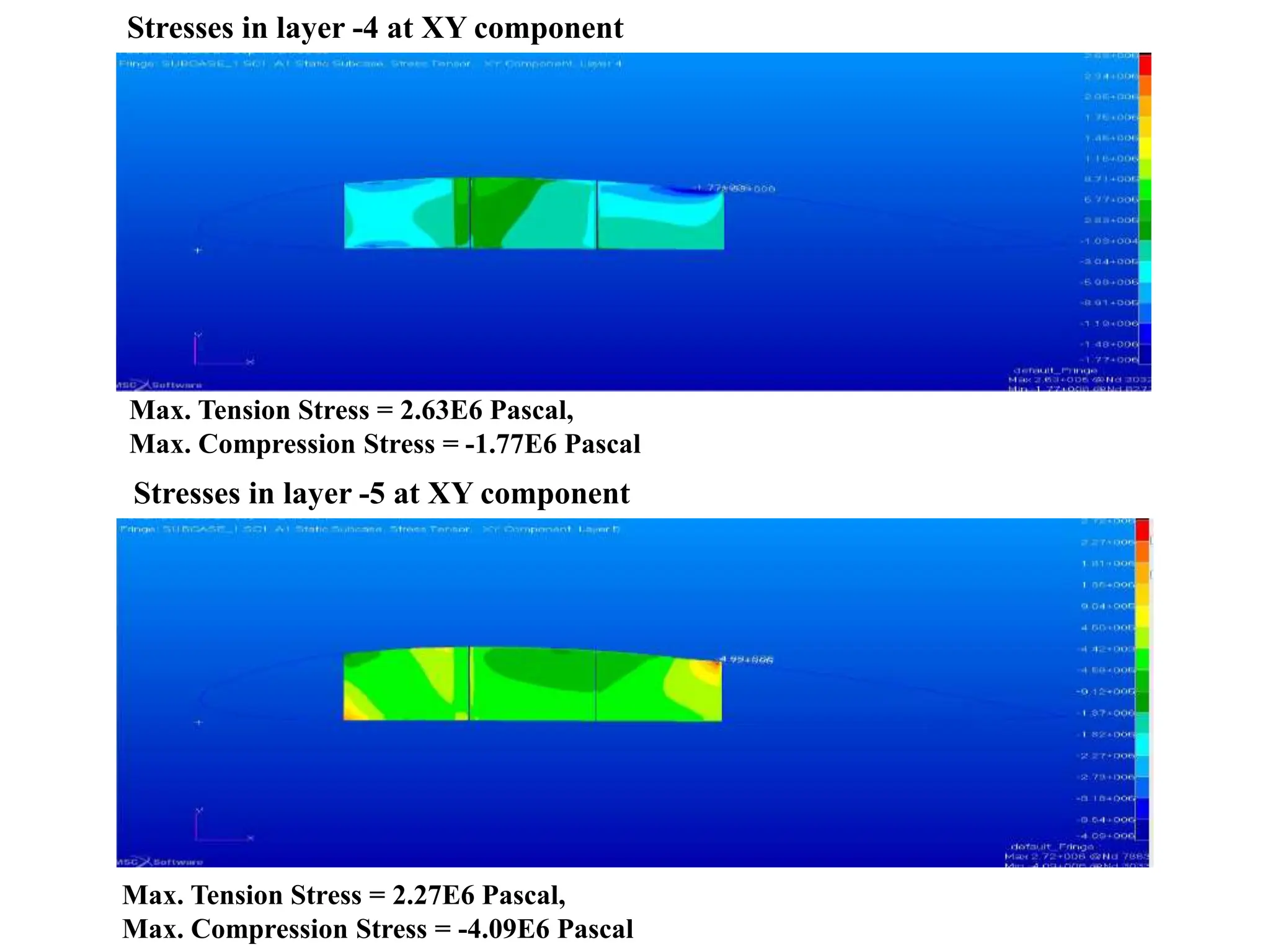

The document presents a final year project focused on the design and analysis of aircraft wing ribs using composite materials through finite element methods. It covers the impact of design parameters, material properties, and the evaluation of stresses and displacements resulting from various fiber orientations. The research utilizes CAD software for design and CAE tools for finite element modeling, leading to significant insights into the structural integrity and optimization of wing rib designs.