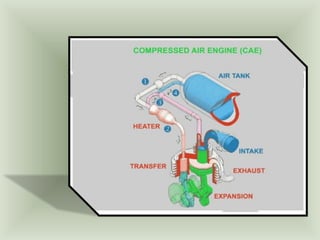

- The document describes an air car invented by Guy Nègre in 1991 that is powered by a compressed air engine instead of a gasoline engine. It produces no emissions and can be refueled quickly by compressed air tanks.

- MDI has developed both single energy compressed air engines for city use and dual energy engines that can run on both compressed air and fuel.

- The air car is projected to have a range of 100-200 miles on compressed air alone depending on traffic conditions, with refueling taking only 3 minutes.