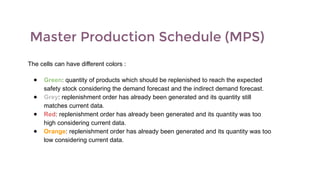

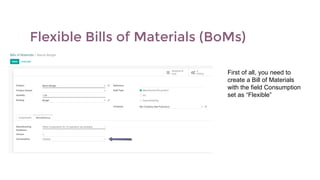

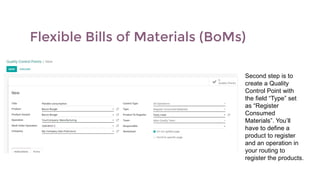

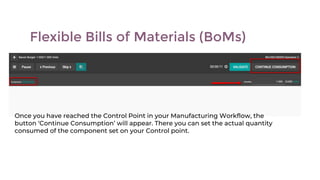

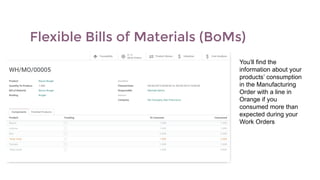

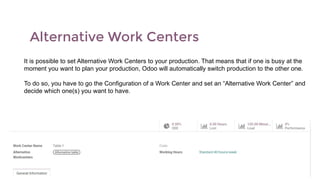

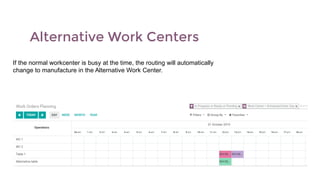

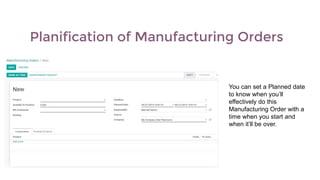

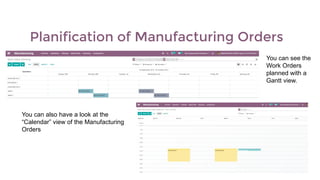

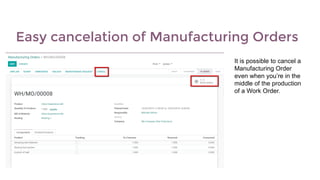

This document discusses new features in Advanced Manufacturing Planning in Odoo. It introduces updates to the Master Production Schedule (MPS) to make it more flexible and detailed. It also covers flexible bills of materials that allow adjusting consumed quantities, alternative work centers that automatically switch production between busy work centers, and new capabilities for planning manufacturing orders with a Gantt view and canceling orders in progress. The presentation concludes with a demo and Q&A section.