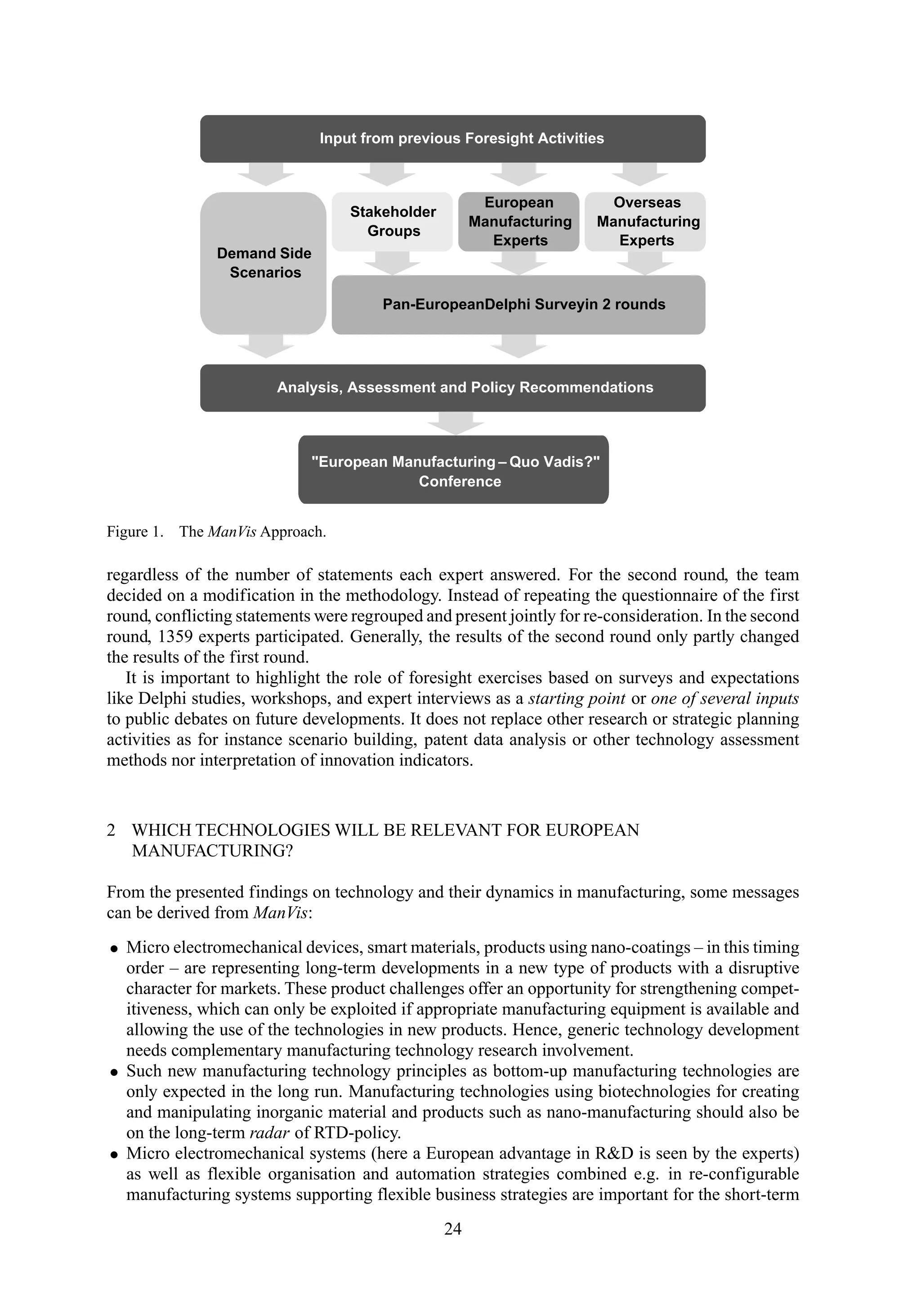

The document is about the publication 'Advanced Manufacturing: An ICT and Systems Perspective', edited by Marco Taisch and others, which summarizes findings from the IMS-NoE project on the future of manufacturing. It discusses the critical role of manufacturing in the European economy and outlines various technology foresight initiatives intended to enhance the competitiveness of the sector amidst increasing global competition. The book serves as a resource for understanding the challenges and opportunities in modern manufacturing, emphasizing ICT's impact on production systems.